Desert improver and processing technology thereof

A processing technology and improver technology, applied in the field of desert improver and its processing technology, can solve the problems of serious water evaporation, difficult water storage, water retention and fertilizer storage, large particle gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

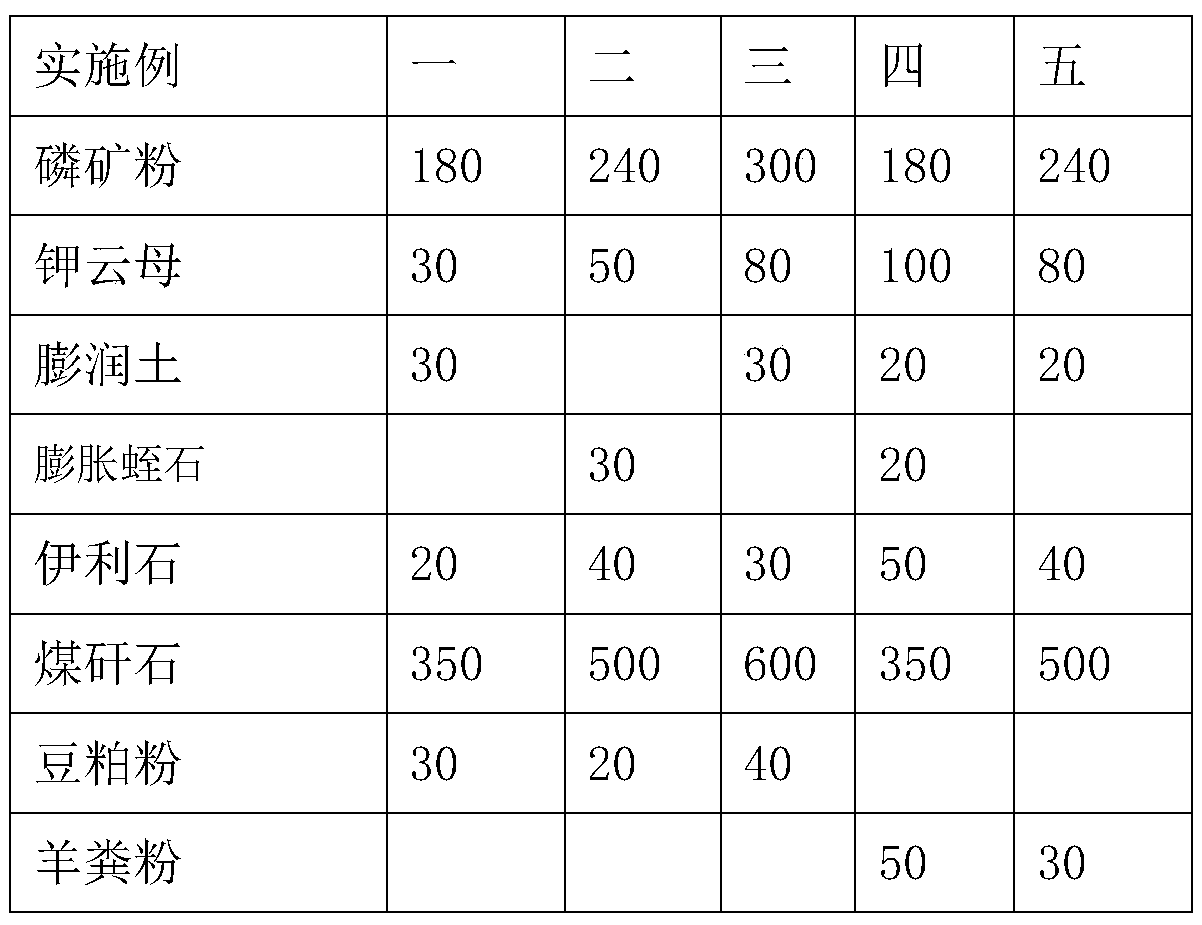

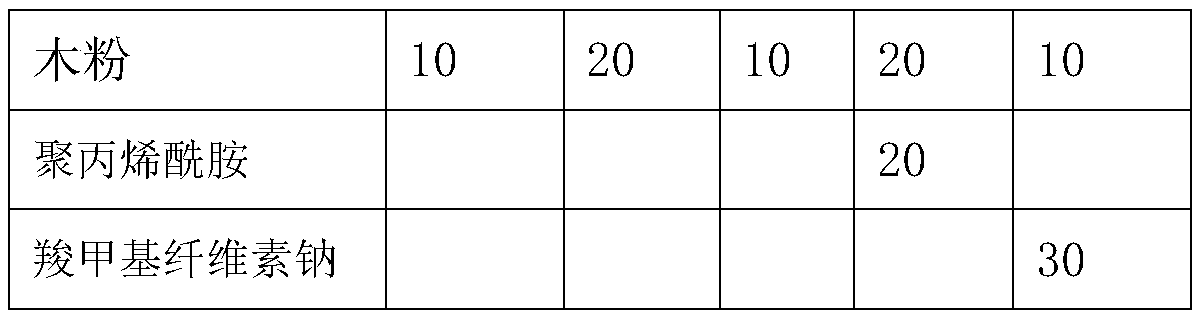

Embodiment 1

[0085] Follow the steps below:

[0086] A, in the ball mill 1, 400kg of phosphate rock powder is processed by the microcrystal activation method, and ground for 8 hours under the energy density condition of 20KW per cubic meter of space, to obtain microcrystal activated phosphate rock powder, and its particle size distribution and volume percentage are: :

[0087] -800~+1300 mesh: 17%;

[0088] -1300~+2000 mesh: 65%;

[0089] -2000 mesh: 15%;

[0090] All the microcrystalline activated phosphate rock powder is discharged and stored in bags;

[0091] B, 50kg of potassium mica and 50kg of bentonite were added to stirring mill 2, and the microcrystal activation method was used to grind for 4 hours under the energy density condition of 45KW per cubic meter of space to obtain potassium-containing microcrystal activated composite mineral powder, its particle size distribution and volume The percentage is:

[0092] -800~+1300 mesh: 50%;

[0093] -1300~+2000 mesh: 32%;

[0094]...

Embodiment 2

[0100] Follow the steps below:

[0101] A, in the ball mill 1, 400kg of phosphate rock powder is processed by the microcrystal activation method, and ground for 6 hours under the energy density condition of 30KW per cubic meter of space, to obtain microcrystal activated phosphate rock powder, and its particle size distribution and volume percentage are: :

[0102] -800~+1300 mesh: 13%;

[0103] -1300~+2000 mesh: 64%;

[0104] -2000 mesh: 20%;

[0105] All the microcrystalline activated phosphate rock powder is discharged and stored in bags;

[0106] B, 100kg of potassium mica and 60kg of expanded vermiculite were added to stirring mill 2, and the microcrystal activation method was used to grind for 4 hours under the condition of an energy density of 55KW per cubic meter of space to obtain a potassium-containing microcrystal activated composite mineral powder with a particle size distribution and volume percentages are:

[0107] -800~+1300 mesh: 51%;

[0108] -1300~+2000 ...

Embodiment 3

[0115] A, by the same operation of embodiment 1 step A, microcrystalline activated phosphate rock powder is obtained;

[0116] B, 120kg of potassium mica and 45kg of bentonite were added to stirring mill 2, and the microcrystal activation method was used to grind for 4 hours under the energy density condition of 55KW per cubic meter of space to obtain potassium-containing microcrystal activated composite mineral powder, its particle size distribution and volume The percentage is:

[0117] -800~+1300 mesh: 60%;

[0118] -1300~+2000 mesh: 22%;

[0119] -2000 mesh: 10%;

[0120] All the potassium-containing microcrystalline activated composite mineral powders are discharged and stored in bags;

[0121] E, in ball mill 1, add 180kg of microcrystalline activated phosphate rock powder that step A makes, 66kg of potassium-containing microcrystalline activated composite mineral powder, illite powder 36kg, wood powder 12kg that step B makes, 15KW in every cubic meter of space Grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com