Green and environmental-friendly heat insulation board

A technology of green environmental protection and thermal insulation board, applied in the direction of thermal insulation, climate change adaptation, insulation improvement, etc., can solve the problems of fire hazards, expensive materials, inability to cut, etc., and meet the requirements of installation thickness and thermal resistance value, production The process and use process are simple, and the effect of reducing the transfer of heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

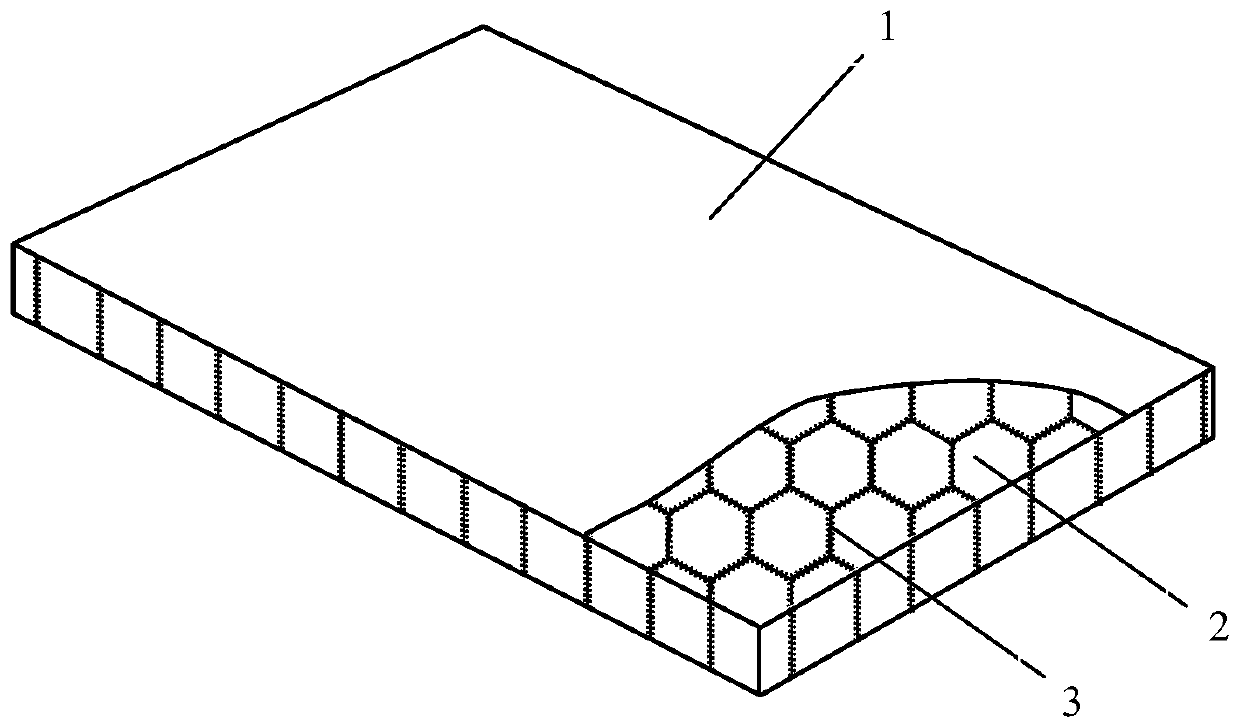

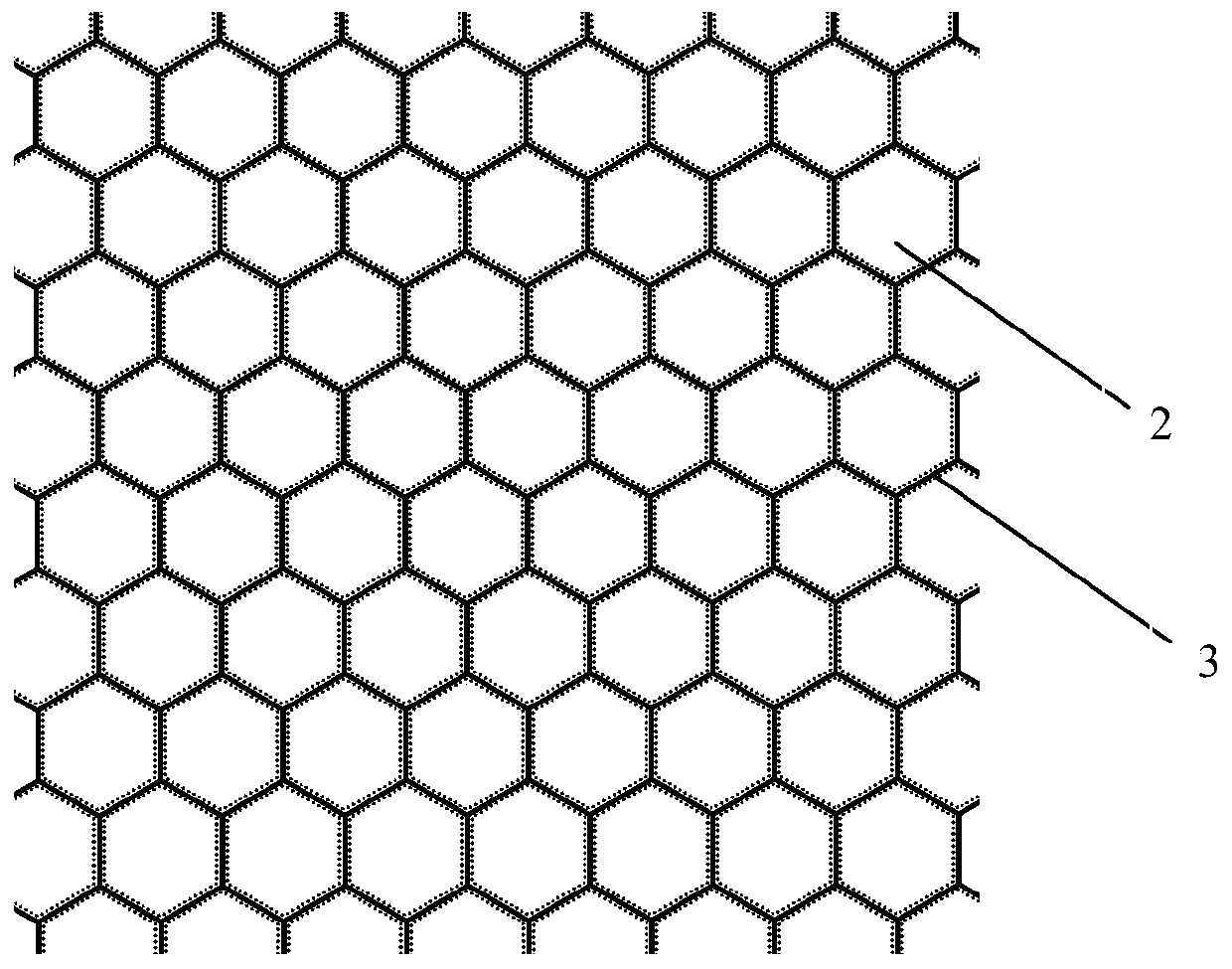

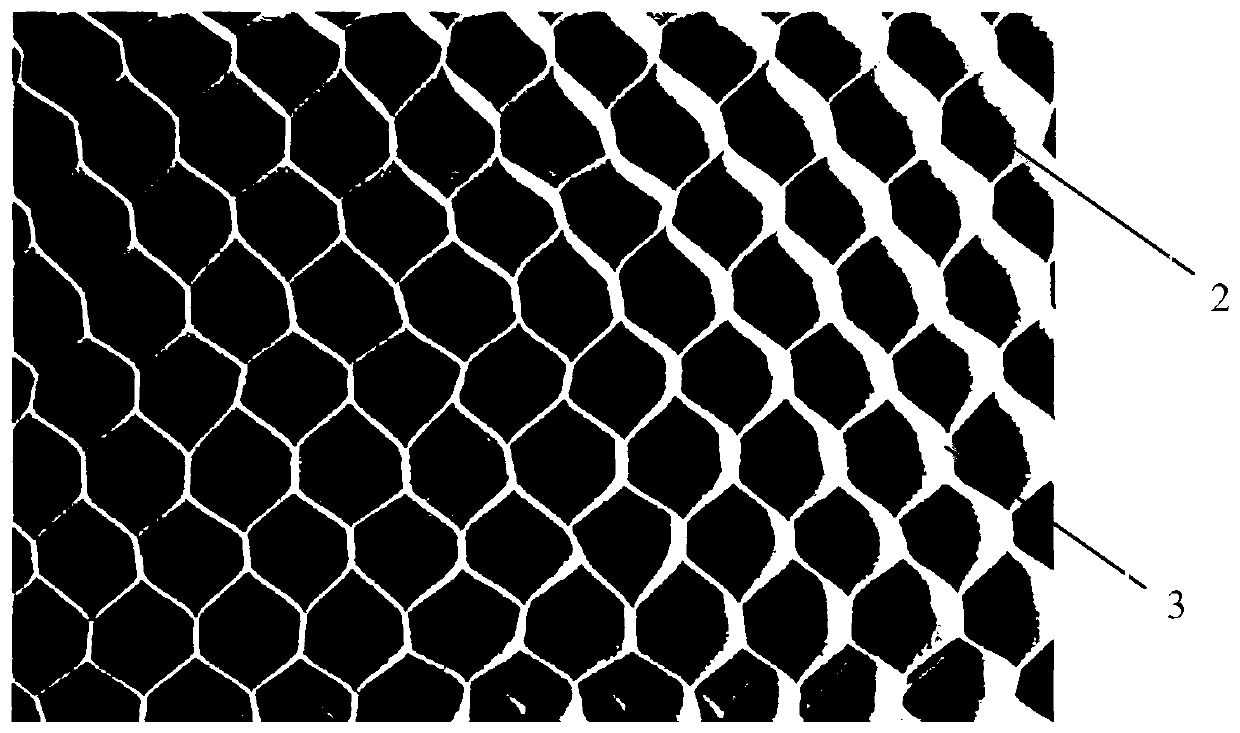

[0044] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0045] As shown in the accompanying drawings, the green environmental protection thermal insulation board of the present invention includes an intermediate support material 3 having a honeycomb hole 2 structure, both sides of the intermediate support material 3 are wrapped with a high gas barrier material layer 1, and the inner surface of the high gas barrier material layer 1 A low-emissivity surface 5 is provided, and the honeycomb holes 2 of the intermediate support material 3 are filled with air, argon, carbon dioxide or a mixture thereof, or vacuumized, and the phonon eutectic 4 is coated on the low-emissivity surface 5, the intermediate support material 3 may be mixed with the intermediate support material, and the high gas barrier material layer 1 and the intermediate support material 3 are bonded by glue.

[0046] The high gas barrier materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com