Room-temperature solid polymer electrolyte and preparation method thereof, and electrode/electrolyte compound and preparation method and application thereof

A solid polymer and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of low ionic conductivity, potential safety hazards, and inapplicability to mass production, etc., to improve volumetric energy density, solve large interface impedance, and design multiple shapes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing a room temperature solid polymer electrolyte described in the above technical solution, comprising the following steps:

[0052] (1) mixing lithium salt, polyethylene oxide, crosslinking agent, additive and photoinitiator to obtain a precursor blend;

[0053] (2) After casting the precursor blend solution on the substrate, cover the film of polyethylene terephthalate, and perform hot-press melting and cooling in sequence to obtain a solid electrolyte precursor;

[0054] (3) The solid electrolyte precursor is irradiated with ultraviolet light to remove the substrate and the polyethylene terephthalate film to obtain a solid polymer electrolyte at room temperature.

[0055] In the present invention, all the preparation raw materials are consistent with the components in the above-mentioned technical solution, and will not be repeated here.

[0056] The invention mixes lithium salt, polyethylene oxide, crosslinking...

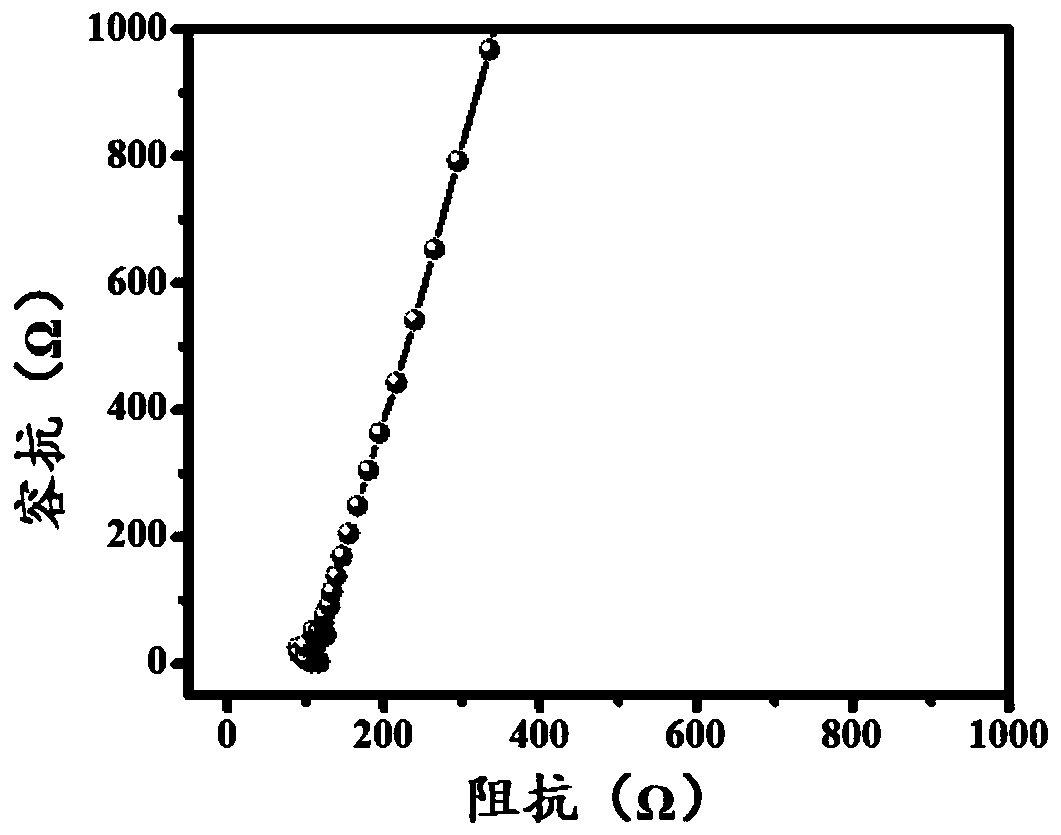

Embodiment 1

[0070] Weigh PEO according to the mass ratio of 1:1:1 (M w =10000g / mol), PEGDMA (M w =750g / mol), poly(oxyethylene siloxane)-[(CH 2 -CH 2 -O-CH 2 -CH 2 -O) 2 SiO] 2 -(M w =440g / mol), and with -EO-: Li + Weigh LiTFSI with a molar ratio of 20:1, stir the above materials for 12 hours to mix them evenly, then add the photoinitiator HMPP weighed at 3% of the total mass of the solid polymer electrolyte at room temperature, stir and mix the above materials and let stand for 6 hours , to obtain a homogeneous precursor blend;

[0071] Precursor blend liquid according to 5mg / cm 2 The casting amount is cast on the PTFE substrate, and heated at 80°C for 20 minutes to obtain the casting material;

[0072] Cover the PET film on the surface of the casting material and perform hot pressing operation. The heating temperature is 80°C and the pressure is 2MPa. Cool down under the condition of circulating water and keep the pressure until it reaches room temperature. The hot pressing tim...

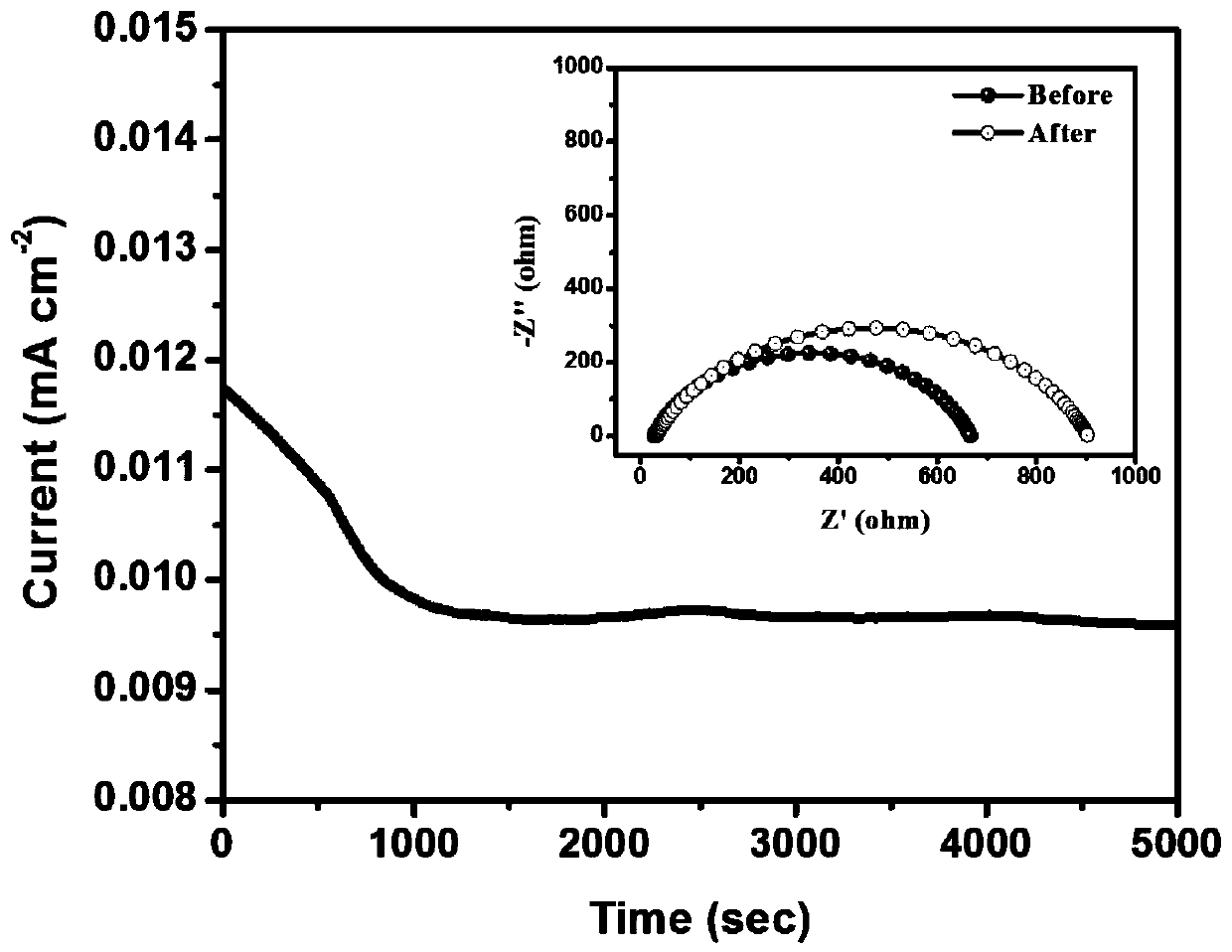

Embodiment 2

[0082] Weigh PEO according to the mass ratio of 1:1:1 (M w =100000g / mol), PEGDMA (M w =750g / mol), poly(oxyethylene siloxane)-[(CH 2 -CH 2 -O-CH 2 -CH 2 -O) 2 SiO] 2 -(M w =440g / mol), and with -EO-:Li + Weigh LiTFSI with a molar ratio of 20:1, stir the above materials for 12 hours to mix them evenly, then add the photoinitiator MBP weighed at 3% of the total mass of the solid polymer electrolyte at room temperature, stir and mix the above materials and let stand for 6 hours , to obtain a homogeneous precursor blend.

[0083] Precursor blend liquid according to 10mg / cm 2 The casting amount is cast on the PTFE substrate and heated at 70°C for 25 minutes to obtain the casting material;

[0084] Cover the surface of the casting material with a PET film and perform a hot pressing operation. The heating temperature is 80°C and the pressure is 3 MPa. Cool down under the condition of circulating water while maintaining the pressure until it reaches room temperature. The hot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar mass | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com