Weight-loss composition and preparation method thereof

A technology of composition and inoculation amount, applied in the directions of bacteria, food science, and application used in food preparation, can solve the problems of people's life and health threats, unclear weight loss mechanism, disturbed metabolic function, etc., and achieves overcoming weight loss mechanism. Single effect, improving habitat environment and increasing satiety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0031] 1. Preparation of modified MRSC medium

[0032] Add the following raw materials to a 30L automatic fermenter: 150g peptone, 150g beef extract, 75g yeast extract, 72g anhydrous sodium acetate, 30g diammonium citrate, 1.5g Tween-80, 8.7g magnesium sulfate, 4.2g manganese sulfate , 30g of dipotassium hydrogen phosphate, 8L of deionized water, and adjust the pH to 6.2-6.4 with liquid caustic soda. Sterilize at 121°C for 20 minutes, then cool down to 37°C. Then add 0.3L of 50% glucose solution that has been sterilized separately, 1.5L of tomato juice that has been sterilized separately, and 100ml of L-cysteine solution with a concentration of 15% that has been sterilized. , the final volume of the fermentation broth is 15L.

[0033] 2. Preparation of inactivated AKK bacteria

[0034] Nitrogen was introduced into the fully automatic fermenter equipped with 15L modified MRSC medium for air replacement. After the dissolved oxygen display value was zero and stable, the repla...

Embodiment example 2

[0048] 1. Preparation of modified MRSC medium

[0049] Add the following raw materials to a 30L automatic fermenter: 150g peptone, 150g beef extract, 75g yeast extract, 72g anhydrous sodium acetate, 30g diammonium citrate, 1.5g Tween-80, 8.7g magnesium sulfate, 4.2g manganese sulfate , 30g of dipotassium hydrogen phosphate, 8L of deionized water, and adjust the pH to 6.2-6.4 with liquid caustic soda. Sterilize at 121°C for 20 minutes, then cool down to 37°C. Then add 0.3L of 50% glucose solution that has been sterilized separately, 1.5L of tomato juice that has been sterilized separately, and 100ml of L-cysteine solution with a concentration of 15% that has been sterilized. , the final volume of the fermentation broth is 15L.

[0050] 2. Preparation of inactivated AKK bacteria

[0051] Nitrogen was introduced into the fully automatic fermenter equipped with 15L modified MRSC medium for air replacement. After the dissolved oxygen display value was zero and stable, the repla...

Embodiment example 3

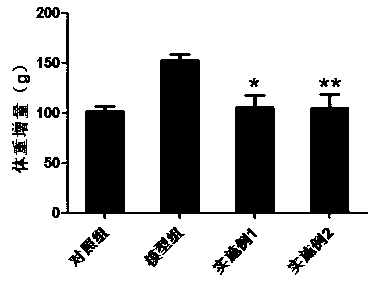

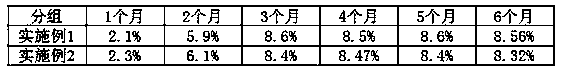

[0065] Animal grouping and dosing:

[0066] Select 40 healthy adult animals (male SD rats, 170±20g), and feed them with common maintenance feed for 7 days, and randomly select 10 animals as blank group respectively. 30 mice were given high-fat model feed (10% sucrose, 12% lard, 10% egg yolk, 1% cholesterol, 0.5% sodium cholate, 66.5% basal feed) and grouped after 1 week, and the suspension was configured according to the implementation case 1-2 liquid (according to the administration of rat body weight per kg, the dose of the weight loss composition is 0.52g / kg), the experimental animals were randomly divided into model group, implementation case 1 group, and implementation case 2 group according to body weight, with 10 animals in each group. The blank control group and the model group were intragastrically administered with the same volume of solvent, that is, deionized water; the remaining groups were intragastrically administered with corresponding weight loss compositions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com