Sludge dewatering method using microbial cracking pretreatment coupled with PAM flocculant chemical flocculation

A technology of chemical flocculation and sludge dehydration, applied in biological sludge treatment, chemical instruments and methods, sludge treatment, etc., can solve the secondary pollution of factory sludge, hygiene and safety, reduce the use of chemical flocculants, and sludge treatment Process difficulties and other problems, to achieve the effect of reducing the biological reaction time and the frequency of microbial agent dosing, increasing the dehydration capacity, and reducing the biological reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

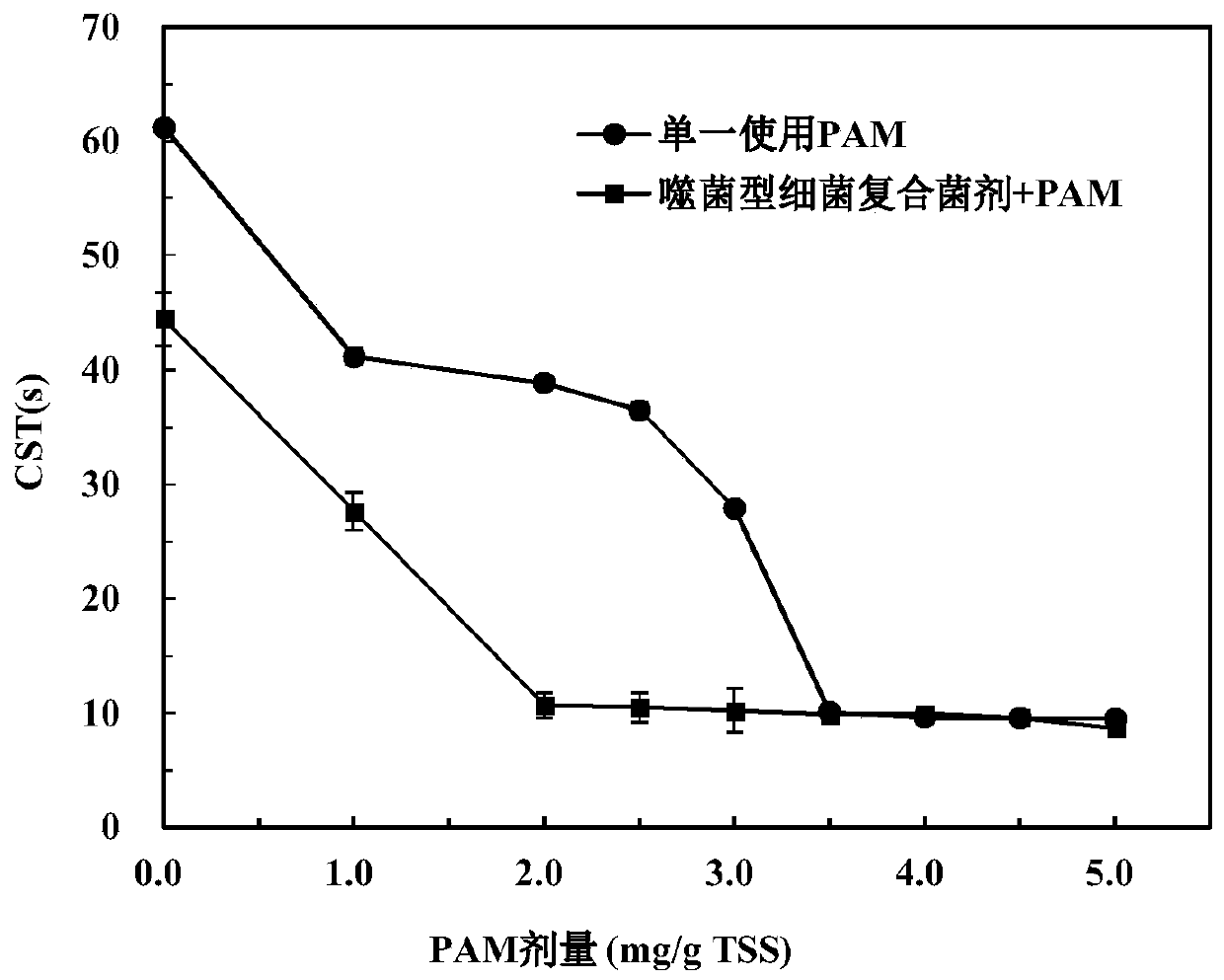

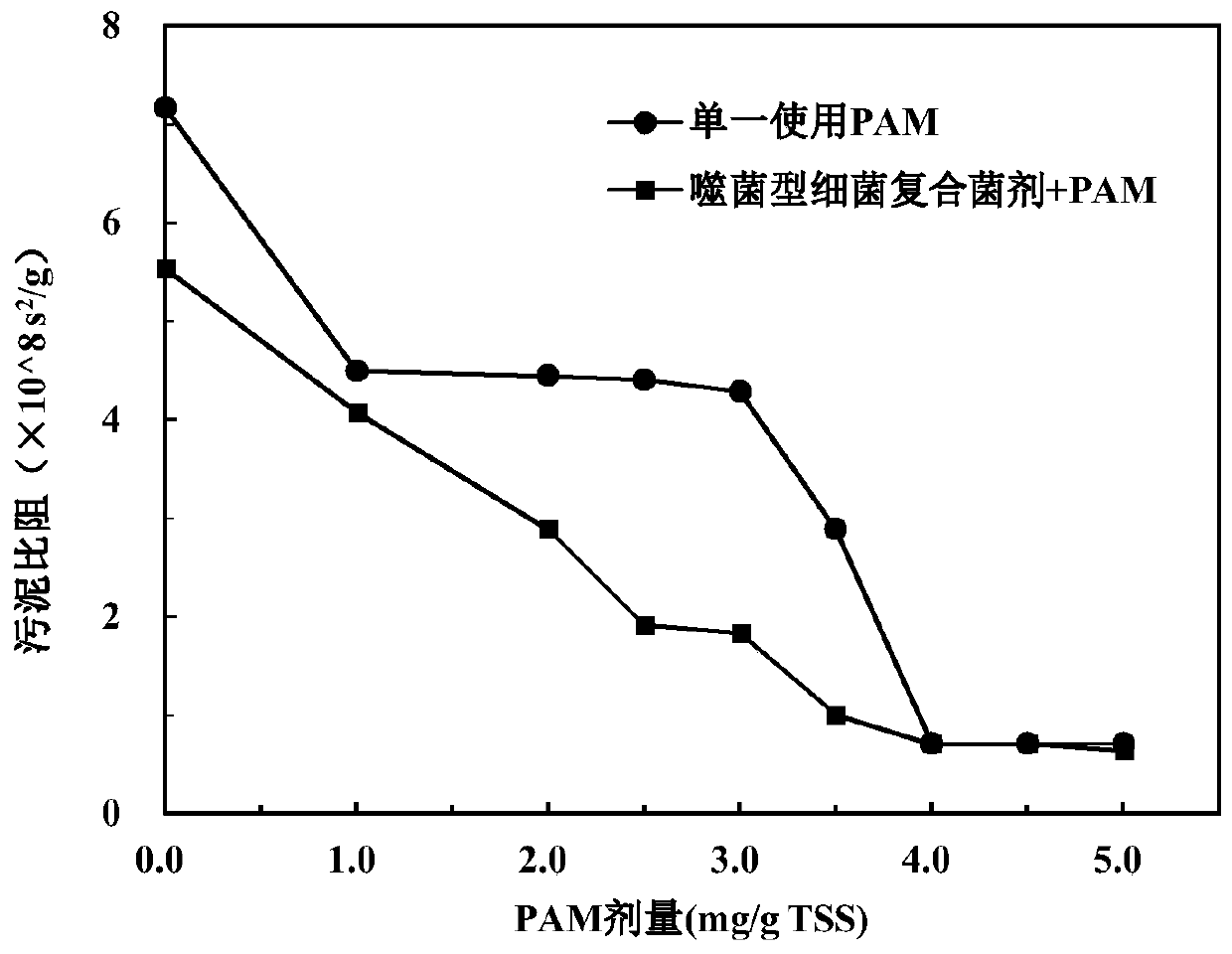

[0030] see figure 1 , figure 2 , using this process to carry out batch treatment of sludge in the laboratory, the treated sludge is the secondary sedimentation tank sludge produced by the oxidation ditch process to treat municipal sewage.

[0031] (1) Preparation of phage-type bacterial compound bacterial agent

[0032] Preparing phage-type Bdellovibrio, Bdellovibrio Stoop, and Bdellovibrio Starr in advance as a phage-type bacterial compound agent The mixed concentration is 10 8 pfu / mL order of magnitude. Among them, the phage-type Bdellovibrio strain is named SDWB01, which was deposited in the General Microbiology Center of China Committee for the Collection of Microorganisms on May 12, 2016, and the preservation number is CGMCC No. 11671.

[0033] Bdellovibrio Stoop and Bdellovibrio Starr can be obtained from common strains by routine screening in sludge.

[0034] (2) Preparation of PAM flocculant solution

[0035] Prepare the PAM flocculant solution in advance: select ...

Embodiment 2

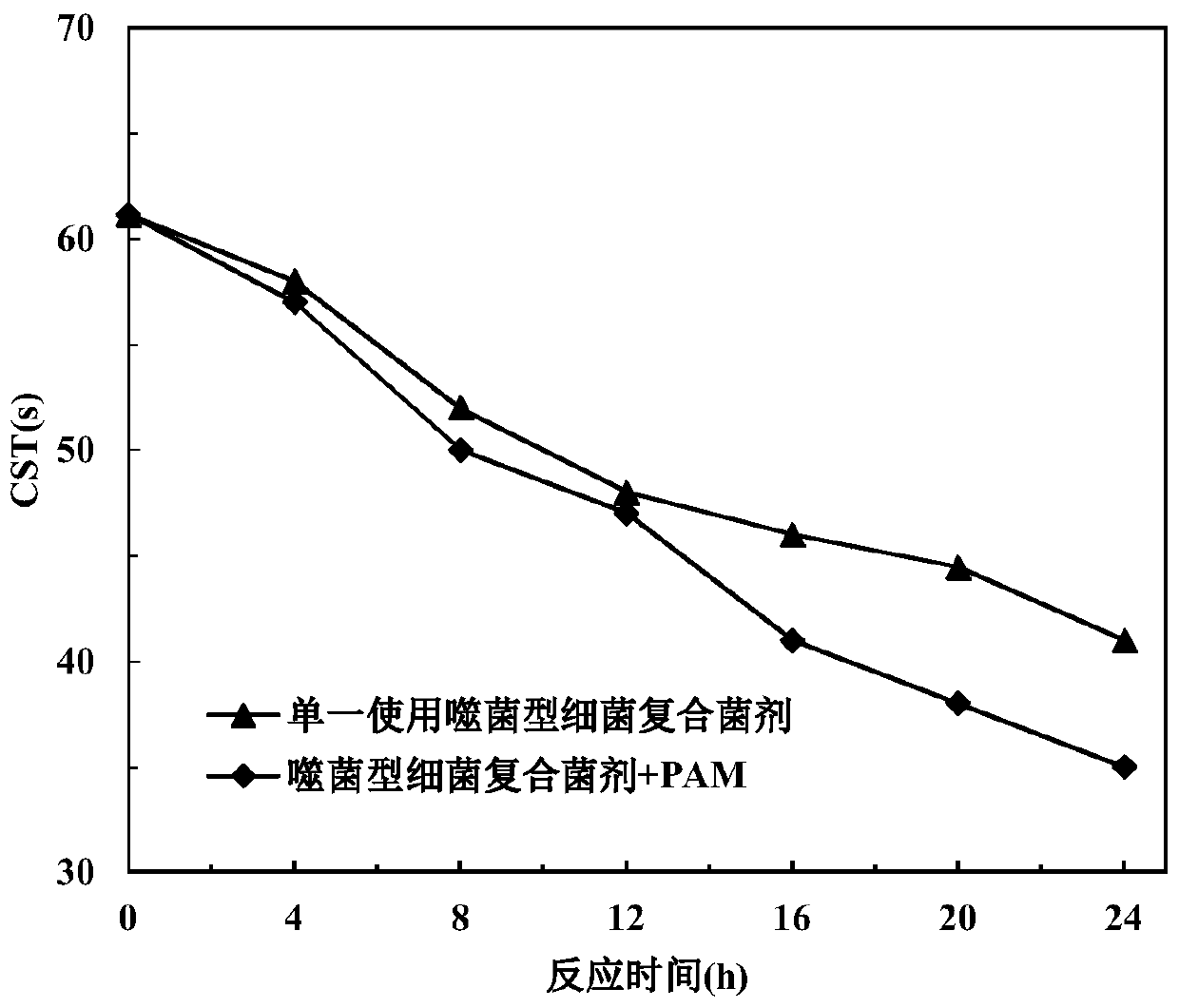

[0049] see image 3 , using this process to carry out batch treatment of sludge in the laboratory, the treated sludge is the secondary sedimentation tank sludge produced by MBR membrane bioreactor process treatment of municipal sewage.

[0050] (1) Preparation of phage-type bacterial compound bacterial agent

[0051] Prepare Bdellovibrio phage, yeast group, and Gram-positive actinomycetes in advance as a bacteriophage-type bacterial compound bacterial liquid, in which Bdellovibrio phage, yeast group, and Gram-positive actinomycetes The mixing concentration is 10 9 pfu / mL order of magnitude. Among them, the bacteriophage Bdellovibrio strain is named SDWB01, which has been preserved in the General Microorganism Center of China Committee for the Collection of Microbial Cultures on May 12, 2016, and the preservation number is CGMCC No. 11671.

[0052] Yeasts and Gram-positive actinomycetes are selected from the yeast products (product number 20205) and gram-positive actinomycet...

Embodiment 3

[0069] see Figure 4 , using this process to carry out batch treatment of sludge in the laboratory, the treated sludge is the secondary sedimentation tank sludge produced by the A2 / O process to treat municipal sewage.

[0070] (1) Preparation of phage-type bacterial compound bacterial agent

[0071] Prepare Bdellovibrio phage, Gram-positive actinomycetes, and filamentous bacteria of the fermentation system in advance as a bacteriophage-type bacterial compound bacterial agent, in which Bdellovibrio phage, Gram-positive actinomycetes , The mixed concentration of the filamentous flora of the fermentation system is 10 6 pfu / mL order of magnitude. Among them, the bacteriophage Bdellovibrio strain is named SDWB01, which has been preserved in the General Microorganism Center of China Committee for the Collection of Microbial Cultures on May 12, 2016, and the preservation number is CGMCC No. 11671. Gram-positive actinomycetes and filamentous bacteria are selected from the Gram-posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com