Chicken manure-fermented fertilizer and preparation method thereof

A chicken manure and fertilizer technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of complex production process, low level of fertilizer utilization, long fermentation time, etc., to shorten fermentation time, improve fertilizer efficiency, The effect of simple fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

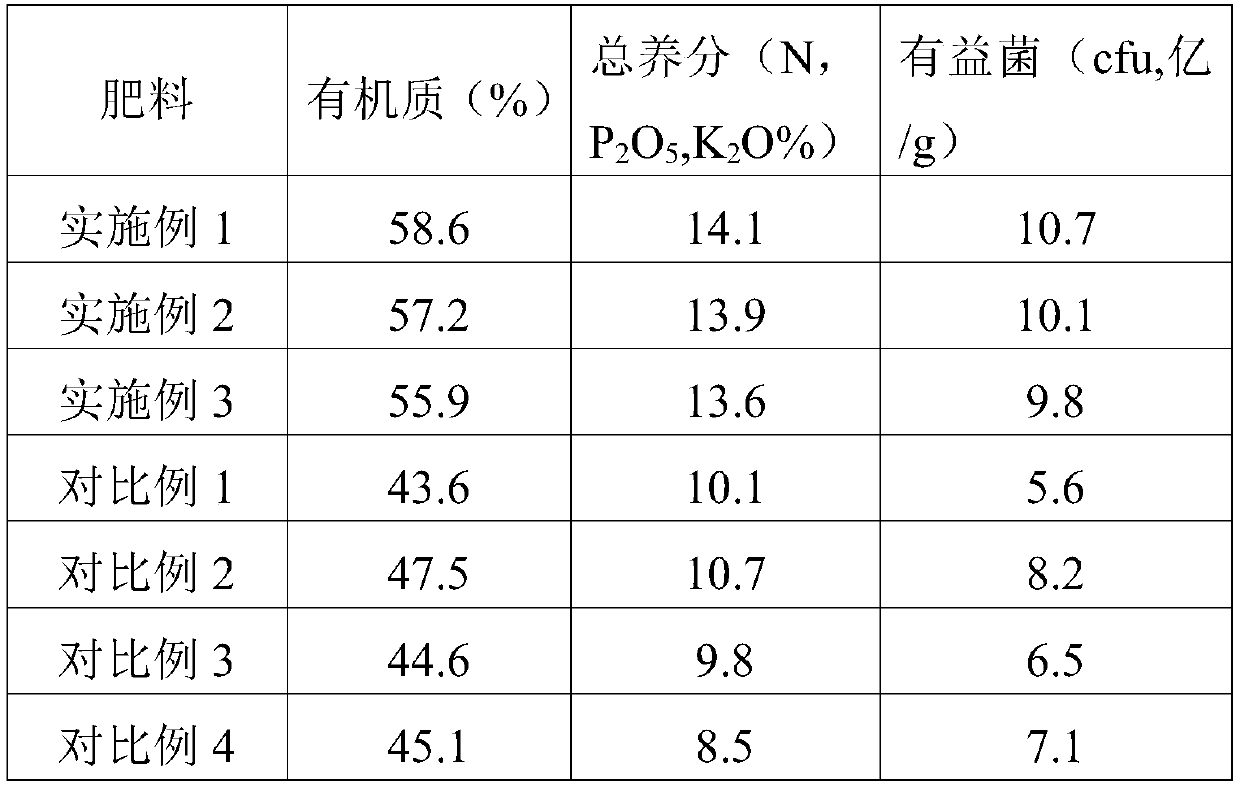

Examples

Embodiment 1

[0023] A fermented chicken manure fertilizer, which is fermented from the following raw materials by weight: 0.2 parts of fermenting bacteria I, 0.1 parts of fermenting bacteria II, 149.8 parts of wood bran, 5 parts of molasses, 2 parts of zeolite powder, and a moisture content of less than 65% 850 pieces of chicken manure.

[0024] Fermentation bacteria I is composed of the following parts by weight: 5 parts of Bacillus subtilis, 5 parts of actinomycetes, 8 parts of thermophilic heterotrophic ammonia oxidizing bacteria, 4 parts of Bacillus licheniformis; fermentation bacteria II is composed of the following parts by weight Strain composition: 4 parts of Bacillus subtilis, 3 parts of lactic acid bacteria, 3 parts of yeasts, 2 parts of Aspergillus oryzae.

[0025] The preparation method of chicken manure fermented fertilizer in this embodiment includes the following steps:

[0026] (1) Dilute the molasses with deionized water to a concentration of 20% solution, add 0.2% superphosphat...

Embodiment 2

[0032] A fermented chicken manure fertilizer, which is fermented from the following raw materials by weight: 0.4 parts of fermenting bacteria I, 0.2 parts of fermenting bacteria II, 199.6 parts of wood bran, 5 parts of molasses, 2 parts of zeolite powder, and a product with a moisture content of more than 65% 800 pieces of chicken manure.

[0033] Fermentation bacteria I consist of the following parts by weight: 8 parts of Bacillus subtilis, 4 parts of actinomycetes, 6 parts of thermophilic heterotrophic ammonia oxidizing bacteria, 2 parts of Bacillus licheniformis; fermentation bacteria II consists of the following parts by weight Strain composition: 3 parts of Bacillus subtilis, 2 parts of lactic acid bacteria, 2 parts of yeast, 1.5 parts of Aspergillus oryzae.

[0034] The preparation method of chicken manure fermented fertilizer in this embodiment includes the following steps:

[0035] (1) Dilute the molasses with deionized water to a concentration of 25% solution, add 0.24% sup...

Embodiment 3

[0041] A fermented chicken manure fertilizer is made by fermenting the following raw materials in parts by weight: 0.5 parts of fermenting bacteria I, 0.2 parts of fermenting bacteria II, 160 parts of wood bran, 7 parts of molasses, 3 parts of zeolite powder, and 900 parts of chicken manure.

[0042] Fermentation bacteria I is composed of the following parts by weight: 5 parts of Bacillus subtilis, 3 parts of actinomycetes, 4 parts of thermophilic heterotrophic ammonia oxidizing bacteria, 2 parts of Bacillus licheniformis; fermentation bacteria II is composed of the following parts by weight Strain composition: 3 parts of Bacillus subtilis, 1 part of lactic acid bacteria, 1 part of yeast, 1 part of Aspergillus oryzae.

[0043] The preparation method of chicken manure fermented fertilizer in this embodiment includes the following steps:

[0044] (1) Dilute the molasses with deionized water to a concentration of 20%, add 0.2% superphosphate, 0.13% ammonium sulfate and 0.02% magnesium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com