Peroxide vulcanized fluororubber with low Mooney viscosity and high fluorine content

A low Mooney viscosity, vulcanized fluorine rubber technology, applied in the field of fluorine chemical industry, can solve the problems of high Mooney viscosity, poor vulcanization effect, easy bubbles in the vulcanized test piece, etc., to achieve the effect of high strength and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

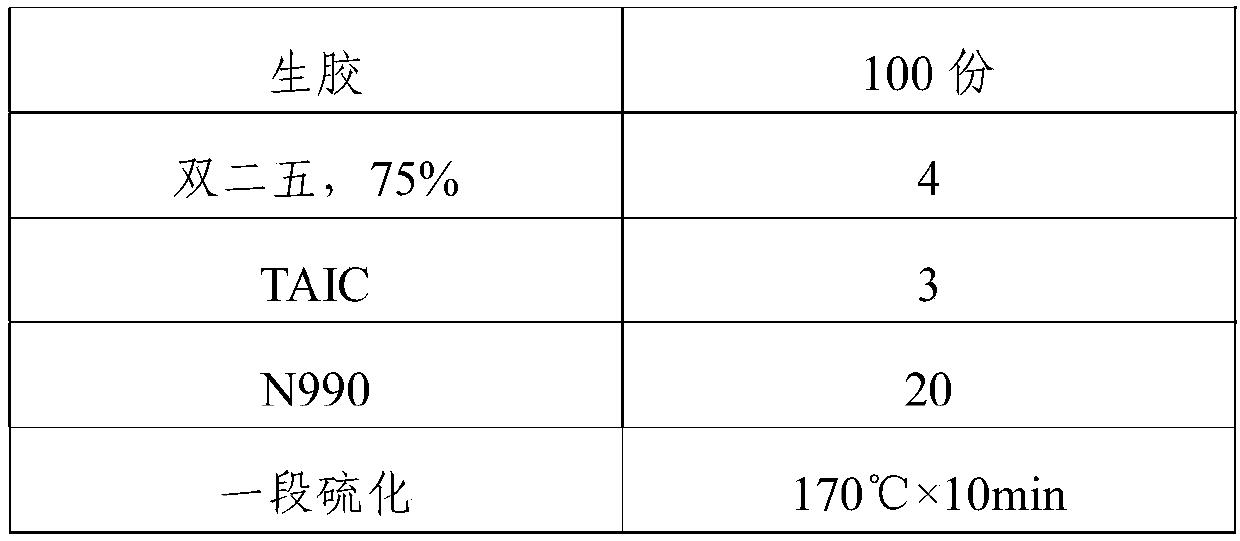

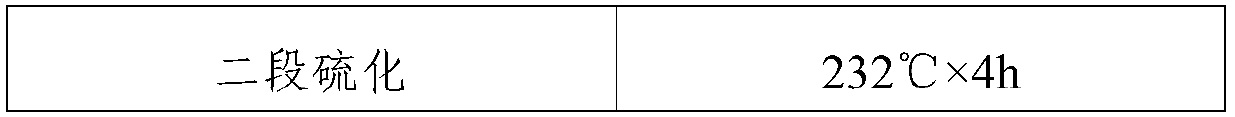

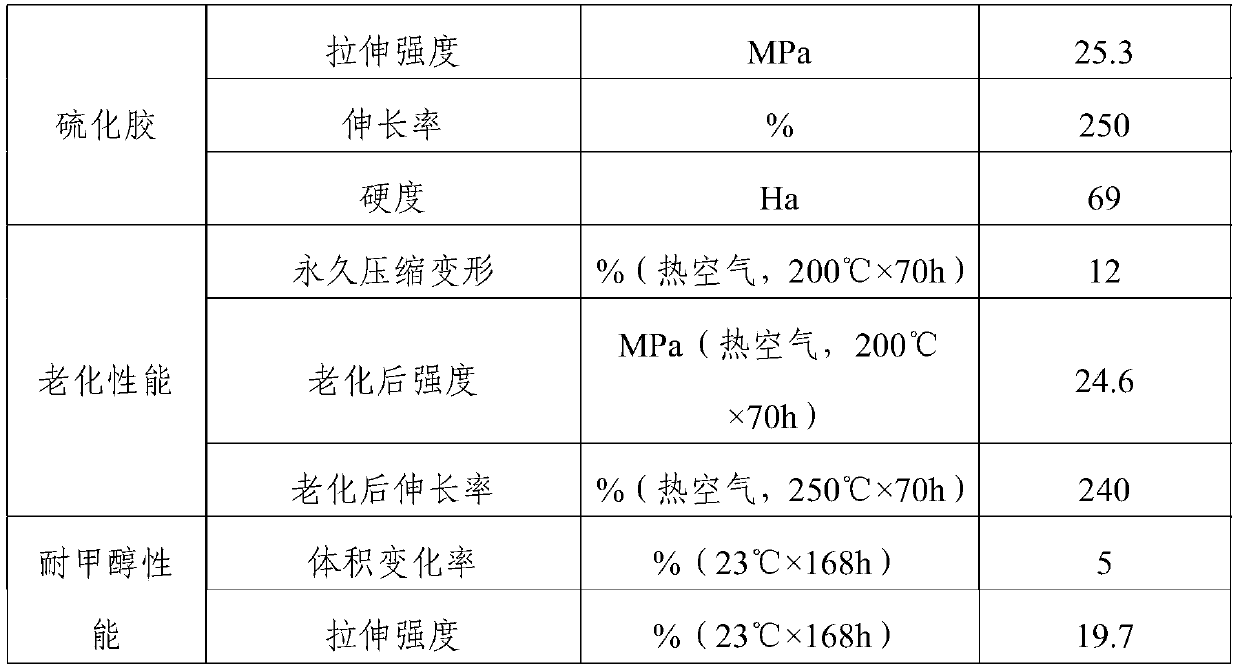

Embodiment 1

[0050] In this embodiment, VDF:TFE:HFP=65:15:20 (molar ratio).

[0051] Add 30L of non-ionized water, 60g of dipotassium hydrogen phosphate, 30g of emulsifier to a 50L stainless steel reactor with a stirrer, vacuumize the reactor until its oxygen content is ≤30ppm, and increase the temperature in the reactor to 80℃ ;

[0052] Add the three main comonomers of VDF / TFE / HFP to the reactor until the pressure in the kettle reaches 4.0MPa; add 400g of 3,3,4,4-tetrafluoro-4-iodobut-1-ene, and add initiator Potassium persulfate 10g, chain transfer agent 1,4-diiodoperfluorobutane 800g, the reaction started, and at the same time, the three main comonomers of VDF / TFE / HFP were added to make the reaction pressure of the reactor within the range of 4.0±0.1MPa.

[0053] With the progress of the reaction, when the cumulative feeding amount reaches 15kg, the feeding is stopped and the reaction is completed; the fluororubber emulsion is obtained, coagulated with magnesium chloride aqueous solution, wa...

Embodiment 2

[0060] In this embodiment, VDF:TFE:HFP=60:20:20 (molar ratio).

[0061] Add 30L of non-ionized water, 60g of dipotassium hydrogen phosphate, 30g of emulsifier to a 50L stainless steel reactor with a stirrer, vacuumize the reactor until its oxygen content is ≤30ppm, and increase the temperature in the reactor to 80℃ ;

[0062] Add the three main comonomers of VDF / TFE / HFP to the reactor until the pressure in the kettle reaches 4.0MPa; add 400g of 3,3,4,4-tetrafluoro-4-iodobut-1-ene, and add initiator Potassium persulfate 10g, chain transfer agent 1,4-diiodoperfluorobutane 700g, the reaction started, and the three main comonomers of VDF / TFE / HFP were added to make the reaction pressure of the reactor within the range of 4.0±0.1MPa.

[0063] With the progress of the reaction, when the cumulative feeding amount reaches 15kg, the feeding is stopped and the reaction is completed; the fluororubber emulsion is obtained, coagulated with magnesium chloride aqueous solution, washed with ion-free...

Embodiment 3

[0068] In this embodiment, VDF:TFE:HFP=30:20:50 (molar ratio).

[0069] Add 30L of non-ionized water, 60g of dipotassium hydrogen phosphate, 30g of emulsifier to a 50L stainless steel reactor with a stirrer, vacuumize the reactor until its oxygen content is ≤30ppm, and increase the temperature in the reactor to 80℃ ;

[0070] Add the three main comonomers of VDF / TFE / HFP to the reactor until the pressure in the kettle reaches 4.5MPa; add 400g of 3,3,4,4-tetrafluoro-4-iodobut-1-ene, and add initiator Potassium persulfate 15g, chain transfer agent 1,4-diiodoperfluorobutane 200g, the reaction started, and the three main comonomers of VDF / TFE / HFP were added to make the reaction pressure of the reactor within 4.5±0.1MPa.

[0071] With the progress of the reaction, when the cumulative feeding amount reaches 15kg, the feeding is stopped and the reaction is completed; the fluororubber emulsion is obtained, coagulated with magnesium chloride aqueous solution, washed with ion-free water, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com