Composite material formula based on graphene powder

A graphene powder and composite material technology, applied in the field of plastics, can solve the problems of low-temperature-resistant modified plastics, such as the decrease of impact toughness and thermal stability, the influence of molding processing performance, and the brittle cracking of parts, so as to improve impact resistance and cold resistance. Good performance, good corrosion resistance, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

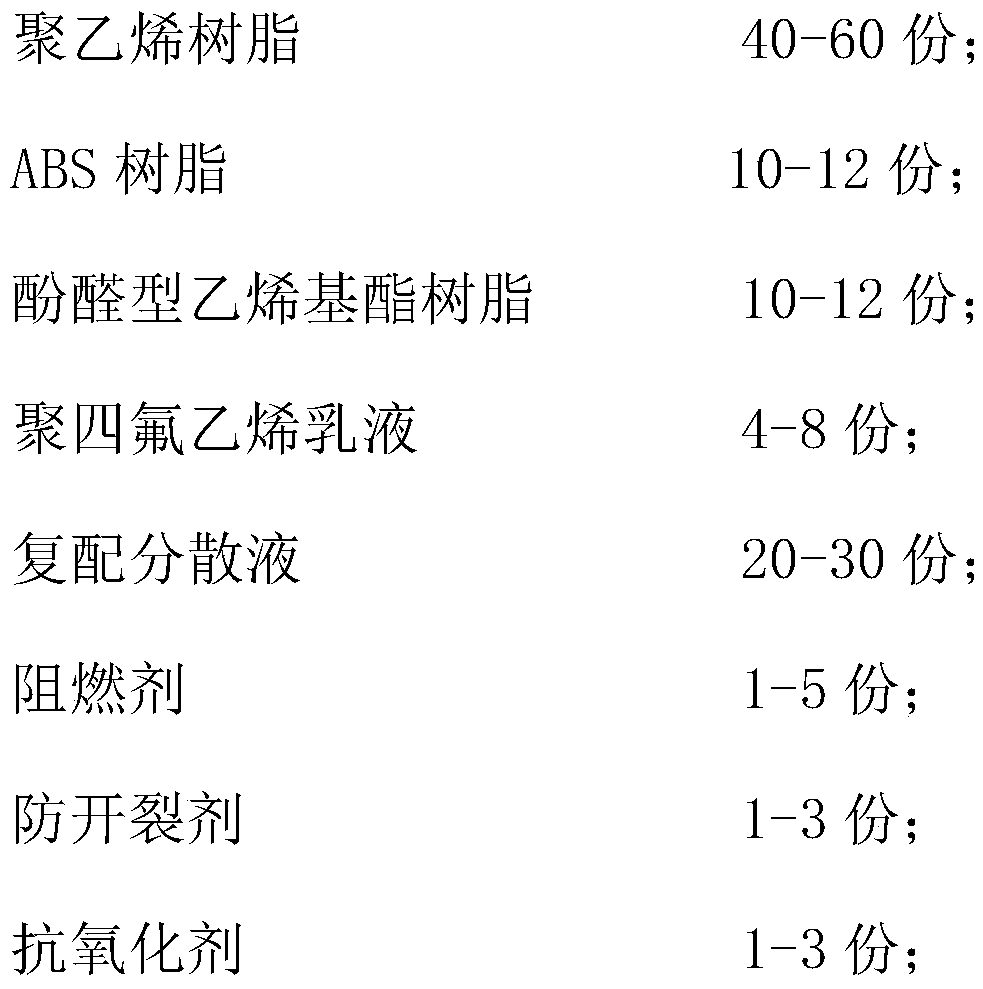

[0033] A kind of composite material formula based on graphene powder, comprises following weight component formula:

[0034]

[0035] The compound dispersion liquid is made of modified graphene powder and modified sepiolite with a mass ratio of 1:1, which are respectively placed in deionized water for graft modification, and the reaction conditions for the graft modification are as follows: 70-120°C, under normal pressure, stirred and reacted for 3h.

[0036] The flame retardant is one of metal compound flame retardants, borosilicate flame retardants, silane coupling agents and combinations thereof.

[0037] The anti-cracking agent is a block copolymer of hydrogenated styrene and butadiene.

[0038] The antioxidant is N-isopropyl-N'-phenyl-p-phenylenediamine.

[0039] The method for preparing plastics by adopting the above-mentioned composite material formula comprises the following steps:

[0040] Step 1. Mixing and stirring the polytetrafluoroethylene emulsion and the ...

Embodiment 2

[0046] The difference from Example 1 is: the difference in formula weight components.

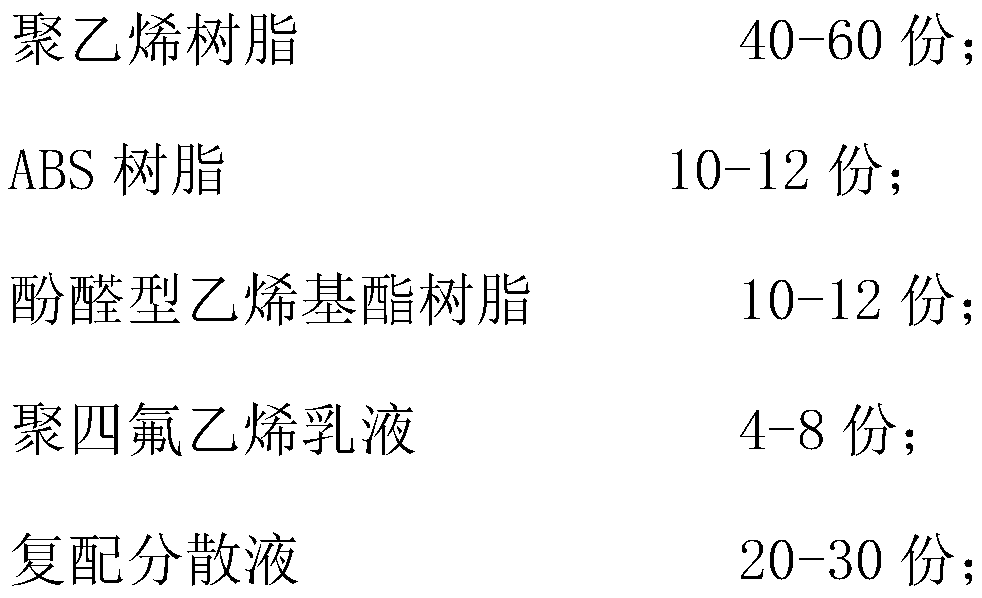

[0047] A kind of composite material formula based on graphene powder, comprises following weight component formula:

[0048]

Embodiment 3

[0050] The difference from Example 1 is: the difference in formula weight components.

[0051] A kind of composite material formula based on graphene powder, comprises following weight component formula:

[0052]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com