Method for improving mechanical properties of calcium sand through fiber reinforced and microbial curing

A fiber-reinforced, microbial technology, applied in the geotechnical-biological-chemical-interdisciplinary field, can solve the problems of poor ductility and brittle failure of the solidified body, reduce brittleness, improve unconfined compressive strength and resistance Tensile strength, the effect of increasing ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In practical application: the 8mm long monofilament chopped basalt fiber and calcareous sand are mixed according to the weight ratio of 1% (the percentage of fiber accounts for sand weight), for example, the quality m of calcareous sand is 27.6g, and the fiber is 0.276g, The mixture is 27.876 grams in total. Stir with a mixer until the fibers are evenly distributed, then fill in 10mm, stop and tamp, then take 8mm long monofilament chopped basalt fibers and mix them with calcareous sand at a ratio of 1%, and stir until the fibers are evenly distributed , stop and tamp after filling 10mm, repeat 10 times until the filling is complete.

[0027] The lyophilized powder of Bacillus pasteurianum was adjusted to pH 7.3 by adjusting the pH to 7.3, and the obtained bacterial liquid was stored in a refrigerator at 4°C and used within 7 days.

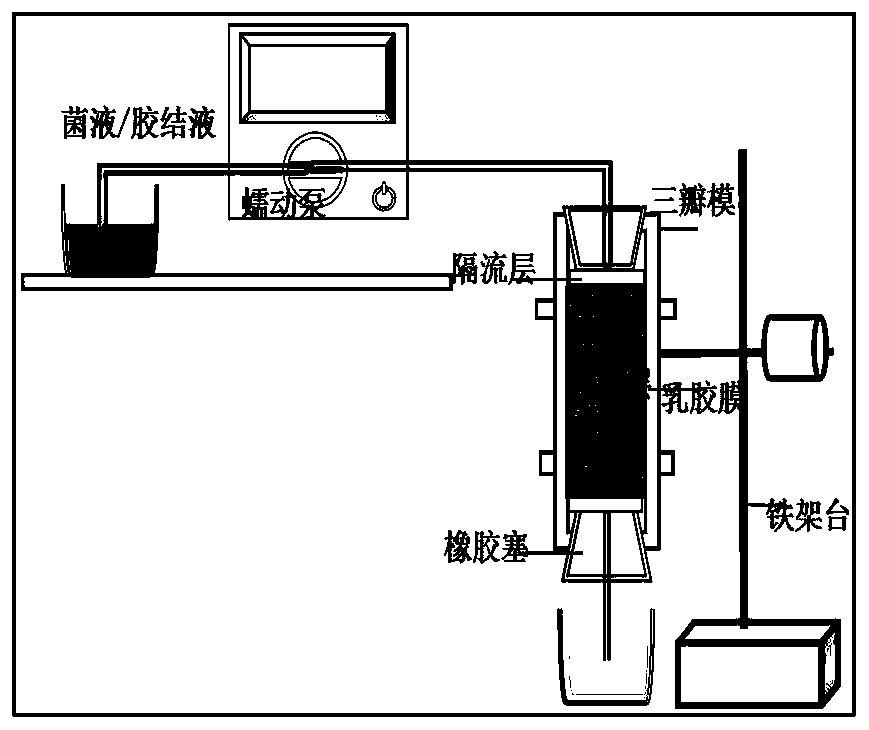

[0028] Into the mixture of loose fibers and sand, use a peristaltic pump to pass the bacterial solution from the upper end and let it stand...

Embodiment 2

[0039] Sample preparation

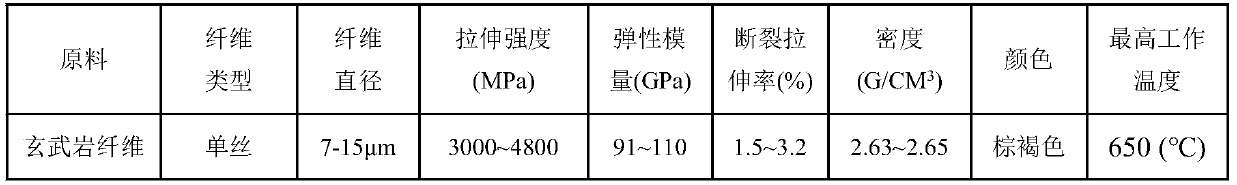

[0040]Take a sample mold with a height of 165mm and a diameter of 50mm, cut it evenly into three pieces, then tighten it with a throat hoop, and cover the inside of the mold with the latex film used in the triaxial test to prevent water leakage; chop the monofilament Basalt fibers (see Table 1 for performance parameters) were mixed into the sand according to the lengths of 4mm, 8mm, 12mm and 18mm, and the fiber contents were 0%, 0.4%, 0.8%, 1% and 1.2% (the percentage of fiber to sand weight) In the calcareous sand, use the method of manual stirring until the fibers are evenly distributed, stop and tamp after filling 10mm, then take new fibers and sand, mix and fill 10mm, stop and tamp, fill 10 times in total, in the sand samples to be solidified The upper and lower ends are respectively equipped with 20mm thick 2-5mm coarse gravel as a barrier layer.

[0041] Table 2 Performance parameters of basalt fiber

[0042]

[0043] A total of 17 groups...

Embodiment 3

[0047] The Activation Culture and Preservation of Bacillus Pasteurella

[0048] The culture medium was prepared, the composition of the culture medium was shown in Table 4, and the solvent was distilled water.

[0049] Table 4 Medium composition

[0050] Element tryptone Peptone Sodium chloride urea content 15g / L 5g / L 5g / L 20g / L

[0051] Dissolve the lyophilized powder of Bacillus pasteurianus (ATCC 11859) in deionized water, then inoculate it into the solid slant medium prepared according to Table 4, cultivate it in a constant temperature incubator at 30°C for 24 hours, and prepare it into a glycerol tube for storage; The glycerol tube was thawed in a water bath and poured into the liquid medium, and then the liquid medium was placed in a constant temperature gyratory shaking incubator with a rotation speed of 130rmp / min and a temperature of 30°C until OD 600 = 1.205, the bacterial solution obtained by adjusting the pH to 7.3 was stored in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com