Fermenting preparation method for nutritional parboiled rice

A technology of parboiled rice and nutrition, which is applied in the field of fermentation and preparation of nutritious parboiled rice, can solve the problems of not promoting parboiled rice market promotion, not satisfying consumers' dietary taste, and difficult to satisfy consumers' taste, so as to avoid Deep yellow color and oily smell, easy to promote, and the effect of improving nutrition and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

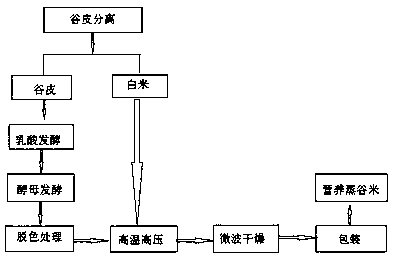

Image

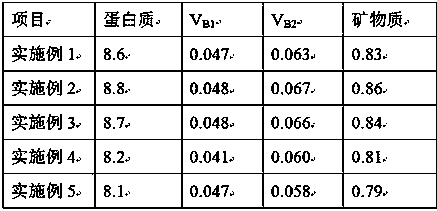

Examples

Embodiment 1

[0026] A fermentation preparation method for nutritional parboiled rice, comprising the following steps:

[0027] The rice is first screened, winnowed, and magnetically separated to remove impurities, and then husked, milled, and winnowed to facilitate the processing of white rice and bran separately in the later stage to obtain white rice and bran; soak the bran in water , the weight of water is 15 times of the weight of paddy rice, stir evenly, insert lactic acid bacteria into water, the inoculation amount is 2%, has carried out secondary activation, is made up of the bacterial strain of following parts by weight: Lactobacillus delbrueckii 6, Lactobacillus bulgaricus 11 , Bifidobacterium 15, centrifuge the strains after the secondary activation, weigh the precipitates according to the weight and mix them, and ferment them at a constant temperature of 38°C for 24 hours, so as to accelerate the destruction of the grain bark structure and facilitate the transformation of macromo...

Embodiment 2

[0029] A fermentation preparation method for nutritional parboiled rice, comprising the following steps:

[0030]The rice is first screened, winnowed, and magnetically separated to remove impurities, and then husked, milled, and winnowed to facilitate the processing of white rice and bran separately in the later stage to obtain white rice and bran; soak the bran in water , the weight of water is 18 times of the weight of paddy rice, stir evenly, insert lactic acid bacteria into water, the inoculation amount is 2.5%, has carried out secondary activation, is made up of the bacterial strain of following parts by weight: Lactobacillus delbrueckii 7, Lactobacillus bulgaricus 12 , Bifidobacterium 16, centrifuge the strains after the secondary activation, weigh the precipitates according to the weight and mix them, and ferment them at a constant temperature of 39°C for 26 hours, so as to accelerate the destruction of the grain bark structure and facilitate the transformation of macrom...

Embodiment 3

[0032] A fermentation preparation method for nutritional parboiled rice, comprising the following steps:

[0033] The rice is first screened, winnowed, and magnetically separated to remove impurities, and then husked, milled, and winnowed to facilitate the processing of white rice and bran separately in the later stage to obtain white rice and bran; soak the bran in water , the weight of water is 20 times of the weight of paddy rice, stir evenly, insert lactic acid bacteria into water, the inoculation amount is 3%, has carried out secondary activation, is made up of the bacterial strain of following parts by weight: Lactobacillus delbrueckii 8, Lactobacillus bulgaricus 13 , Bifidobacterium 17, centrifuge the strains after the secondary activation, weigh the precipitates by weight and mix them, and ferment them at a constant temperature of 40°C for 28 hours, so as to accelerate the destruction of the grain bark structure and facilitate the transformation of macromolecular nutrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com