A preparation method of gutta-percha tip composite material suitable for sls printing

A composite material and gutta-percha technology, which is applied in the field of preparation of gutta-percha tip composite materials, can solve the problems of lack of individuality and the accuracy of tooth roots needs to be improved, and achieve excellent antibacterial effect, good mechanical properties and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

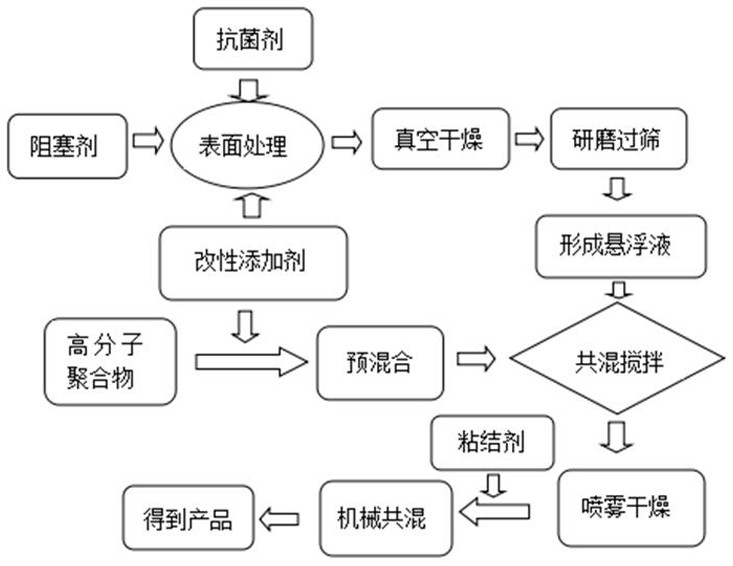

Image

Examples

Embodiment 1

[0031] A preparation method for a gutta-percha tip composite material suitable for SLS printing, comprising the following steps:

[0032] (1) Modify nano-barium sulfate and nano-zinc oxide respectively, and then make suspensions according to the mass ratio of modified nano-barium sulfate or modified nano-zinc oxide:ethylene glycol 1:20 respectively; the modification treatment includes the following Steps: first dissolve the titanate coupling agent in an appropriate amount of ethanol at 45°C, add an appropriate amount of nano barium sulfate, the mass ratio of nano barium sulfate: titanate coupling agent: absolute ethanol is 15:4:100, Set the stirring speed at 300r / min and the modification time at 60min for surface treatment and modification. After the reaction, filter with suction, wash the filter cake with absolute ethanol, and heat it in a vacuum oven set at 60°C to Drying, then pulverizing and refining with a fast pulverizer with a rotation speed of 1500r / min, and passing th...

Embodiment 2

[0039] A preparation method for a gutta-percha tip composite material suitable for SLS printing, comprising the following steps:

[0040] (2) Modify nano-zirconia and nano-silver respectively, and then make a suspension according to modified nano-barium sulfate or modified nano-silver: isopropanol = 1:20; the modification process includes the following steps: first Dissolve stearic acid in an appropriate amount of absolute ethanol at 40°C, add an appropriate amount of nano-zirconia, nano-zirconia: stearic acid: absolute ethanol = 15:6:120, set the stirring speed to 400r / min and The modification time is 40 minutes for surface treatment and modification. After the reaction is completed, suction filter, wash the filter cake with absolute ethanol, and heat to dry in a vacuum oven with a set temperature of 80°C, and then set the rotation speed to 2000r / Min’s fast pulverizer pulverizes, refines, and passes through a sieve of more than 300 meshes to finally obtain modified nano-zirc...

Embodiment 3

[0047] A preparation method for a gutta-percha tip composite material suitable for SLS printing, comprising the following steps:

[0048] (3) Modify nano-barium sulfate and nano-zinc oxide respectively, and then prepare suspensions according to modified nano-barium sulfate or modified nano-zinc oxide: ethylene glycol = 1:20; modification includes the following steps : First dissolve oleic acid in an appropriate amount of ethanol at 40°C, add appropriate amount of nano-barium sulfate and nano-zinc oxide, nano-barium sulfate: oleic acid: absolute ethanol = 15:4:100, set the stirring speed to Surface treatment and modification under the conditions of 400r / min and modification time of 70min. After the reaction, filter with suction, wash the filter cake with absolute ethanol, and heat to dry in a vacuum oven with a set temperature of 80°C. The fast pulverizer set at 3000r / min pulverizes, refines, and passes through a sieve of more than 300 meshes to finally obtain modified nano-bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com