Preparation method of polypropylene imine modified magnetic nanocrystalline cellulose molecular imprinted polymer

A technology of nanocrystalline cellulose and polypropylene imine, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low utilization rate of imprinted polymer molecules, and achieve the effect of improving utilization rate and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

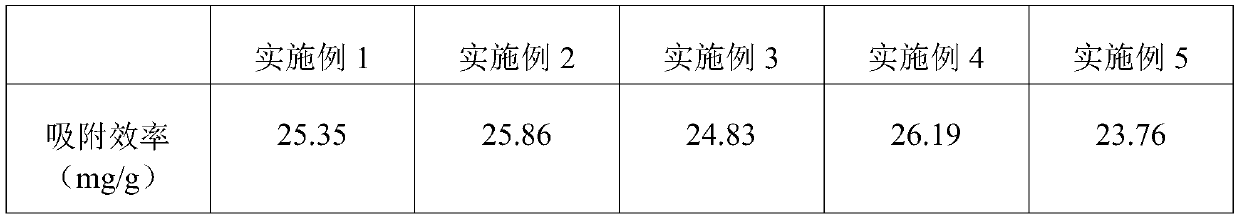

Examples

Embodiment 1

[0021] A method for preparing a polypropyleneimine-modified magnetic nanocrystalline cellulose molecularly imprinted polymer, comprising the following steps:

[0022] 1) Add 3g nanocrystalline cellulose to 150mL deionized water and ultrasonically disperse to form a dispersion liquid, add 2g FeCl to the dispersion liquid 3 ·6H 2 O and 5g FeCl 2 4H 2 O, dropwise adding sodium hydroxide with a concentration of 10 wt% to adjust the pH to 9.5, react at 35° C. for 3 h, separate the product from the solution with a magnet, wash, and dry to obtain magnetic nanocrystalline cellulose;

[0023] 2) Add 3-(2,3-epoxypropoxy)propyltrimethoxysilane into toluene solvent and stir to dissolve to obtain 2wt% 3-(2,3-epoxypropoxy)propyltrimethoxysilane Silane solution, adding the magnetic nanocrystalline cellulose obtained in step 1) to the solution, stirring and reacting, separating the solid product, washing, and drying to obtain alkylated magnetic nanocrystalline cellulose;

[0024] 3) addin...

Embodiment 2

[0027] A method for preparing a polypropyleneimine-modified magnetic nanocrystalline cellulose molecularly imprinted polymer, comprising the following steps:

[0028] 1) Add 3g nanocrystalline cellulose to 150mL deionized water and ultrasonically disperse to form a dispersion liquid, add 2g FeCl to the dispersion liquid 3 ·6H 2 O and 6g FeCl 2 4H 2 O, dropwise adding sodium hydroxide with a concentration of 10 wt% to adjust the pH to 10, react at 40° C. for 2 h, separate the product from the solution with a magnet, wash, and dry to obtain magnetic nanocrystalline cellulose;

[0029] 2) Add 3-(2,3-epoxypropoxy)propyltrimethoxysilane into toluene solvent and stir to dissolve to obtain 3-(2,3-epoxypropoxy)propyltrimethoxysilane with a concentration of 4wt%. Silane solution, adding the magnetic nanocrystalline cellulose obtained in step 1) to the solution, stirring and reacting, separating the solid product, washing, and drying to obtain alkylated magnetic nanocrystalline cellu...

Embodiment 3

[0033] A method for preparing a polypropyleneimine-modified magnetic nanocrystalline cellulose molecularly imprinted polymer, comprising the following steps:

[0034] 1) Add 3g nanocrystalline cellulose to 150mL deionized water and ultrasonically disperse to form a dispersion liquid, add 2g FeCl to the dispersion liquid3 ·6H 2 O and 4g FeCl 2 4H 2 O, dropwise adding sodium hydroxide with a concentration of 10 wt% to adjust the pH to 9.5, react at 30° C. for 5 h, separate the product from the solution with a magnet, wash, and dry to obtain magnetic nanocrystalline cellulose;

[0035] 2) Add 3-(2,3-epoxypropoxy)propyltrimethoxysilane into toluene solvent and stir to dissolve to obtain 3-(2,3-epoxypropoxy)propyltrimethoxysilane with a concentration of 1.5wt%. base silane solution, adding the magnetic nanocrystalline cellulose obtained in step 1) to the solution, stirring and reacting, separating the solid product, washing, and drying to obtain alkylated magnetic nanocrystalline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com