Solid phase microextraction head and preparation method and application thereof

A solid-phase microextraction head and extraction technology, which is applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of sensitivity improvement and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

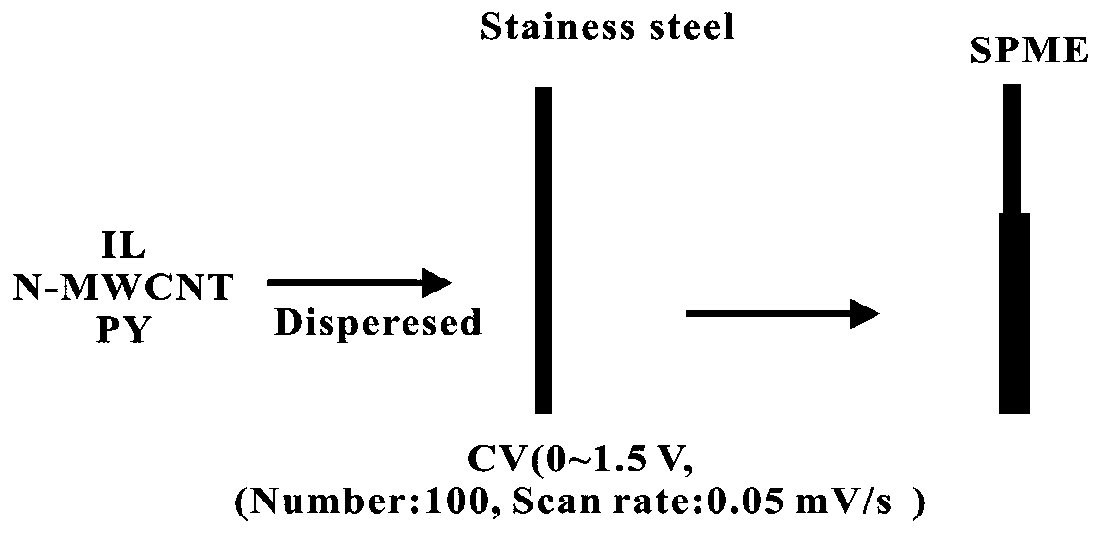

[0044] Embodiment 1: the preparation (PPY) of solid-phase microextraction head

[0045] Such as figure 1As shown, the platinum wire as the counter electrode, the saturated calomel electrode as the reference electrode and the stainless steel wire as the working electrode were assembled into a three-electrode electrochemical working system. In the range of 0-1.5V cyclic voltammetry, scan 100 cycles at a speed of 0.05mV / s, then take out the prepared SPME head, rinse with ethanol and deionized water to remove impurities on the surface, and dry it for later use. Afterwards, the extraction head was bonded to the handle of the self-made injector in this experiment with a mixed resin of epoxy resin and polyamide resin at a ratio of 1:1, and dried in the air. Extraction injector. Next, insert the SPME head into the GC inlet through the injection handle, and age the extraction head for 5 minutes at a temperature of 250°C in the inlet.

Embodiment 2

[0046] Embodiment 2: the preparation of solid phase microextraction head (PPY-IL)

[0047] Such as figure 1 As shown, the platinum wire as the counter electrode, the saturated calomel electrode as the reference electrode and the stainless steel wire as the working electrode were assembled into a three-electrode electrochemical working system, and the three electrodes were immersed in a solution containing 40.0 μL / mL pyrrole and 2.0 mg / mL In the mixed solution of 1-butyl-3-methylimidazolium hexafluorophosphate (IL) liquid, in the voltage range of 0-1.5V cyclic voltammetry, scan 100 cycles at a speed of 0.05mV / s, and then take out The prepared SPME head was rinsed with ethanol and deionized water to remove impurities on the surface, and dried for later use. Afterwards, the extraction head was bonded to the handle of the self-made injector in this experiment with a mixed resin of epoxy resin and polyamide resin at a ratio of 1:1, and dried in the air. Headspace solid phase micr...

Embodiment 3

[0048] Embodiment 3: Preparation of solid phase microextraction head (PPY-IL-N-MWCNT)

[0049] Such as figure 1 As shown, the platinum wire as the counter electrode, the saturated calomel electrode as the reference electrode and the stainless steel wire as the working electrode were assembled into a three-electrode electrochemical working system. In the mixed solution of mL carbon nanotube (N-MWCNT) and 2.0mg / mL 1-butyl-3-methylimidazolium hexafluorophosphate (IL) liquid, in the voltage range of 0-1.5V cyclic voltammetry, with Scan at a speed of 0.05mV / s for 100 cycles, then take out the prepared SPME head, rinse with ethanol and deionized water to remove surface impurities, and dry it for later use. Afterwards, the extraction head was bonded to the handle of the self-made sample injector in this experiment with a mixed resin of epoxy resin and polyamide resin at a ratio of 1:1, dried in the air, and the extraction head containing (PPY+IL+N- MWCNT) manual headspace solid-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com