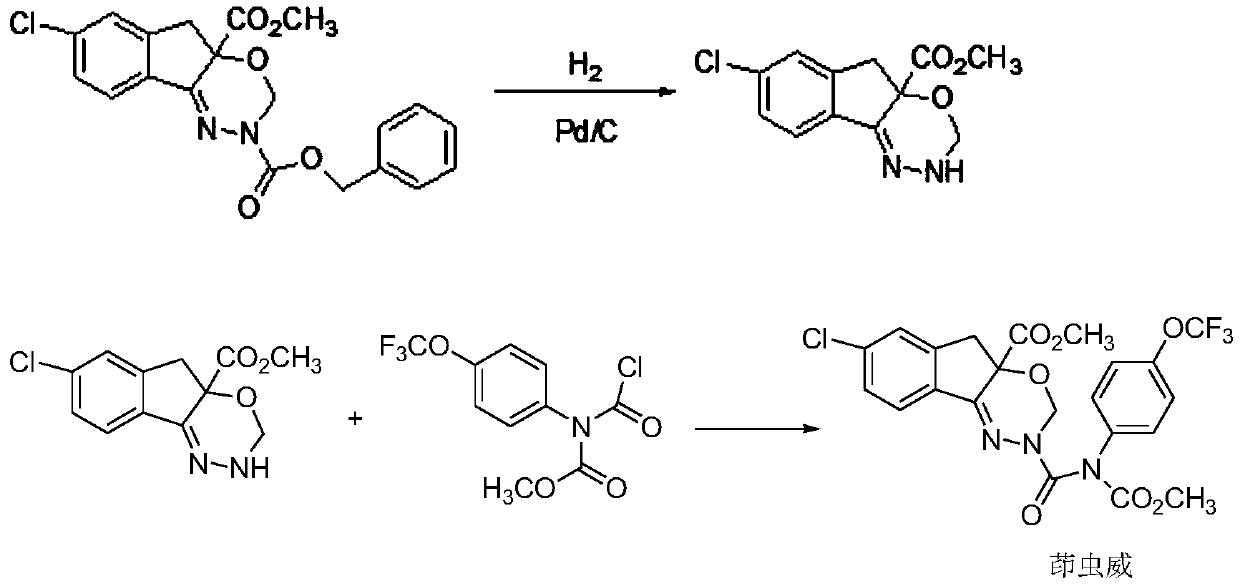

Palladium catalyst for synthesis of indoxacarb intermediates and preparation method

The technology of a palladium catalyst and an intermediate is applied in the field of palladium catalyst for synthesizing indoxacarb intermediates and its preparation, and can solve the problems of reducing catalyst activity, lengthening reaction time, difficulty in operation and the like, achieving enhanced selectivity and stability, The effect of hindering migration and aggregation, reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

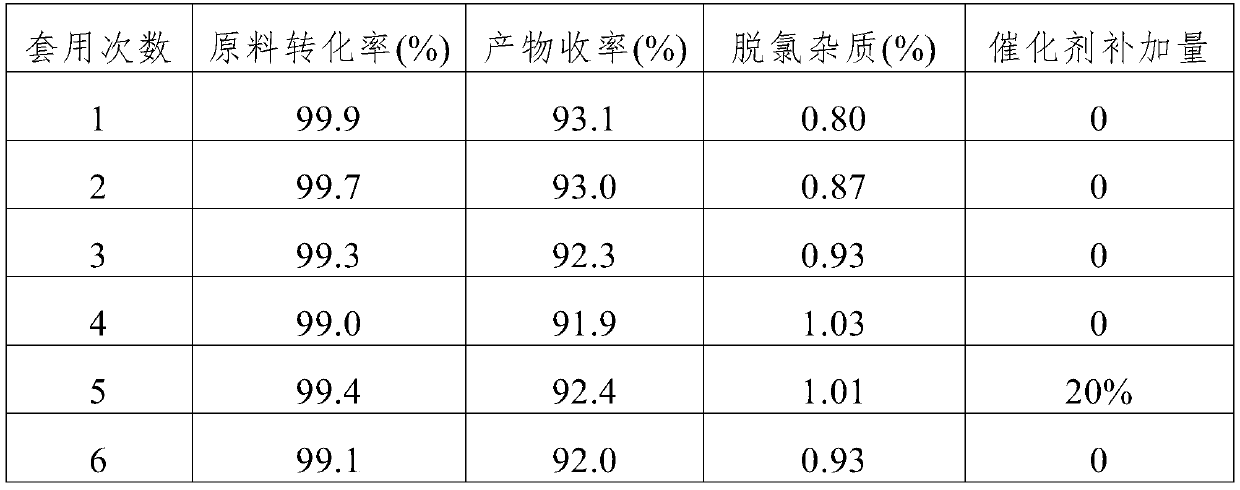

Examples

Embodiment 1

[0033] The palladium catalyst for the synthesis of indoxacarb intermediates of the present embodiment includes a carrier and an active component and a metal-helping component loaded on the carrier; the carrier is a mixture of activated carbon and carbon nanotubes, and the activated carbon is wood powder activated carbon. Surface area is 1000m 2 / g, the mass percentage of carbon nanotubes in the mixture of activated carbon and carbon nanotubes is 0.5%; the active component is Pd, the metal-helping component is Fe, and the mass percentage of Pd in the catalyst is 5%, and the mass percentage of Fe is 0.5%.

[0034] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0035] Step 1, adding 19.9g of activated carbon and 0.1g of carbon nanotubes to deionized water and ultrasonic treatment for 30min, then adding 0.1g of dopamine hydrochloride to obtain a slurry; adjusting the pH of the slurry with a tris buffer solution to 8.5, stirred...

Embodiment 2

[0041] The palladium catalyst for the synthesis of indoxacarb intermediates of the present embodiment includes a carrier and an active component and a metal-helping component loaded on the carrier; the carrier is a mixture of activated carbon and carbon nanotubes, and the activated carbon is wood powder activated carbon. Surface area is 1400m 2 / g, the mass percentage of carbon nanotubes in the mixture of activated carbon and carbon nanotubes is 2%; the active component is Pd, the metal-helping component is Fe, and the mass percentage of Pd in the catalyst is 5%, and the mass percentage of Fe is 1.5%.

[0042] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0043] Step 1, adding 19.6g of activated carbon and 0.4g of carbon nanotubes to deionized water and ultrasonic treatment for 20min, then adding 0.35g of dopamine hydrochloride to obtain a slurry; adjusting the pH of the slurry with tris buffer solution to 8, stirred and ...

Embodiment 3

[0049] The palladium catalyst for the synthesis of indoxacarb intermediates of the present embodiment includes a carrier and an active component and a metal-helping component loaded on the carrier; the carrier is a mixture of activated carbon and carbon nanotubes, and the activated carbon is wood powder activated carbon. Surface area is 1800m 2 / g, the mass percentage of carbon nanotubes in the mixture of activated carbon and carbon nanotubes is 5%; the active component is Pd, the metal-helping component is Fe, and the mass percentage of Pd in the catalyst is 5%, and the mass percentage of Fe is 2.5%.

[0050] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0051] Step 1, adding 19.0 g of activated carbon and 1.0 g of carbon nanotubes into deionized water and ultrasonically treating it for 40 min, then adding 0.6 g of dopamine hydrochloride to obtain a slurry; adjusting the pH of the slurry with tris buffer solution to 9.0,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com