Phthalimide glycidyl ester epoxy resin and preparation method thereof

A technology of glyceride epoxy resin and phthalimide, which is applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., can solve the problem of unsatisfactory heat resistance and achieve good application prospects and sources Convenience, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

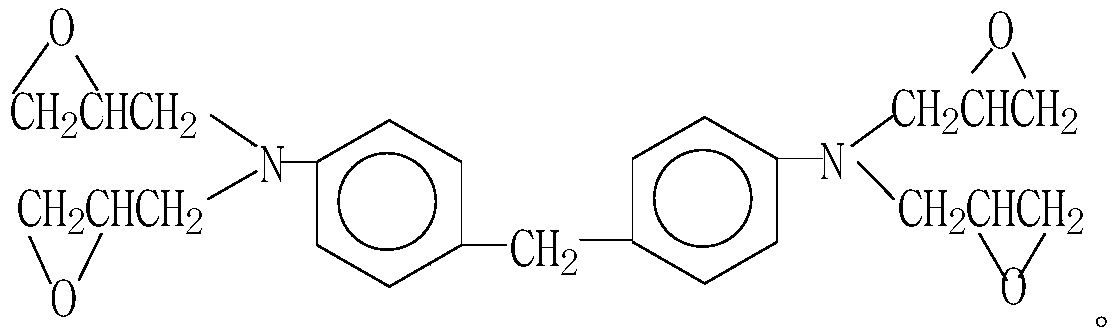

Image

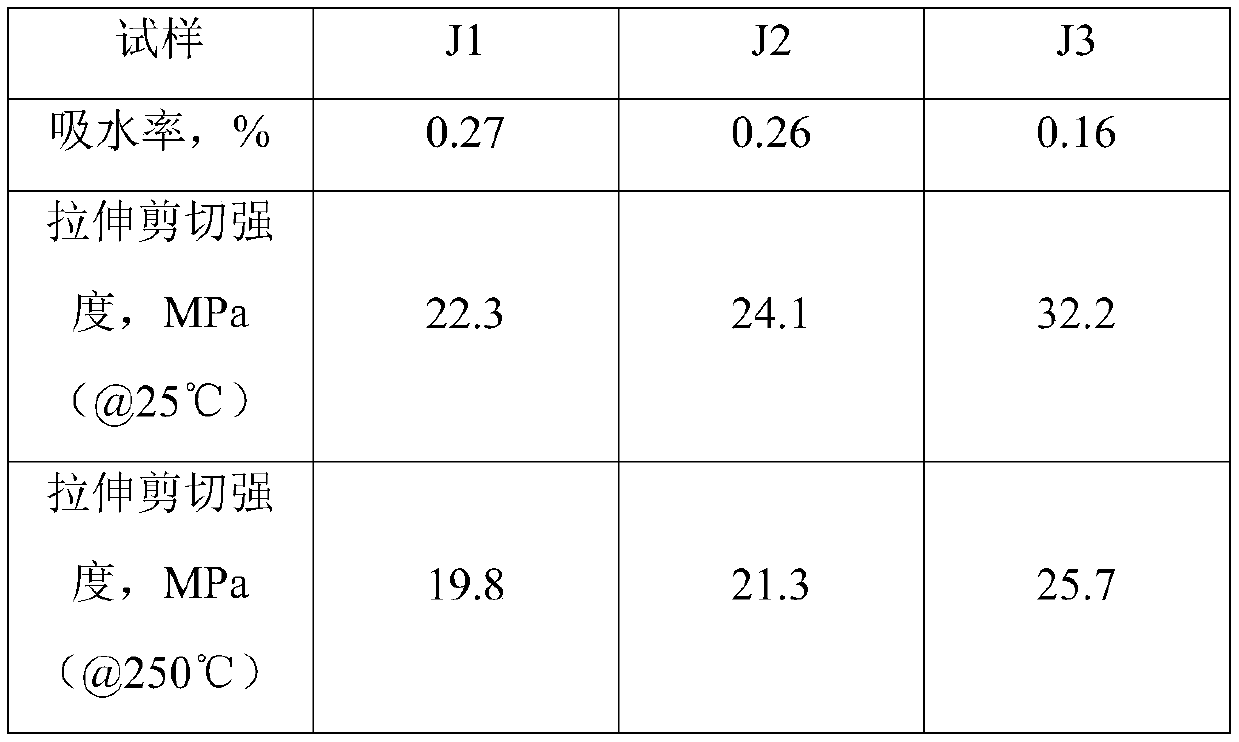

Examples

Embodiment 1

[0025] Add 192.0 grams (1.0 mol) of trimellitic anhydride and 576.0 grams of N,N-dimethylacetamide into the reaction kettle. After stirring and dissolving at room temperature, add 100.0 grams (0.5 mol) of 4,4'-diaminodiphenyl ether at room temperature. Under stirring for 0.5-2.0 hours, 1150g of toluene was added, heated to azeotropic dehydration reaction for 5-15 hours, cooled to below 80℃, then added 925.0g (10.0mol) of epichlorohydrin, at 80℃-100℃ Stir and react for 1 hour to 8 hours, distill under reduced pressure, recover the solvent and epichlorohydrin, add 40.0 g (1.0 mol) of sodium hydroxide, add 40.0 g of water, and stir and react at 80°C-100°C for 1 hour to 8 hours. Desalting, washing with water, and vacuum devolatilization to obtain 320.2 g of phthalimide glycidyl ester epoxy resin (theoretical yield is 330.0 g), which is recorded as TE1, the yield is 97.0%, and the measured epoxy value is 0.26.

Embodiment 2

[0027] Add 192.0 grams (1.0 mol) of trimellitic anhydride and 1455 grams of N,N-dimethylformamide into the reaction kettle. After stirring and dissolving at room temperature, add 99.0 grams (0.5 mol) of 4,4'-diaminodiphenylmethane at room temperature. Under stirring for 0.5-2.0 hours, 150g of toluene was added, heated to azeotropic dehydration reaction for 5-15 hours, cooled to below 80℃, and 111.0g (1.2 moles) epichlorohydrin was added at 80℃-100℃ Stir and react for 1 hour to 8 hours, distill under reduced pressure, recover the solvent and epichlorohydrin, add 80.0 g (2.0 moles) of sodium hydroxide, add 400.0 g of water, and stir and react at 80°C-100°C for 1 hour to 8 hours. Desalting, washing with water, and vacuum devolatilization, to obtain 296.7 g of phthalimide glycidyl ester epoxy resin (theoretical yield is 329.0 g), denoted as TE2, the yield is 90.1%, and the measured epoxy value is 0.21.

Embodiment 3

[0029] Add 192.0 g (1.0 mol) of trimellitic anhydride, 352 g of N-ethyl-2-pyrrolidone and 1000 g of N,N-dimethylformamide into the reaction kettle. After stirring and dissolving at room temperature, add 146.0 g (0.5 mol) 1 ,3-Bis(4-aminophenoxy)benzene, stir and react at room temperature for 0.5-2.0 hours, then add 1000 g of toluene and 352 g of xylene, heat and increase azeotropic dehydration reaction for 5-15 hours, cool to 80°C Then add 462.5 grams (5.0 moles) of epichlorohydrin, stir and react at 80℃-100℃ for 1 hour to 8 hours, distill under reduced pressure, recover the solvent and epichlorohydrin, and add 60.0 grams (1.5 moles) of sodium hydroxide , Add 180.0 grams of water, stir and react at 80℃-100℃ for 1 hour-8 hours, remove the salt, wash with water, and vacuum devolatilize to obtain 365.2 grams of phthalimide glycidyl epoxy resin (theoretical yield is 376.0 grams) , Recorded as TE3, the yield was 97.1%, and the measured epoxy value was 0.25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com