Outdoor type water-based corrosion-resistant finish paint and preparation method thereof

A water-based, outdoor technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems that cannot meet long-term anti-corrosion, anti-rust, impact resistance, etc., and achieve bright and full appearance, smooth paint film, and excellent anti-corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

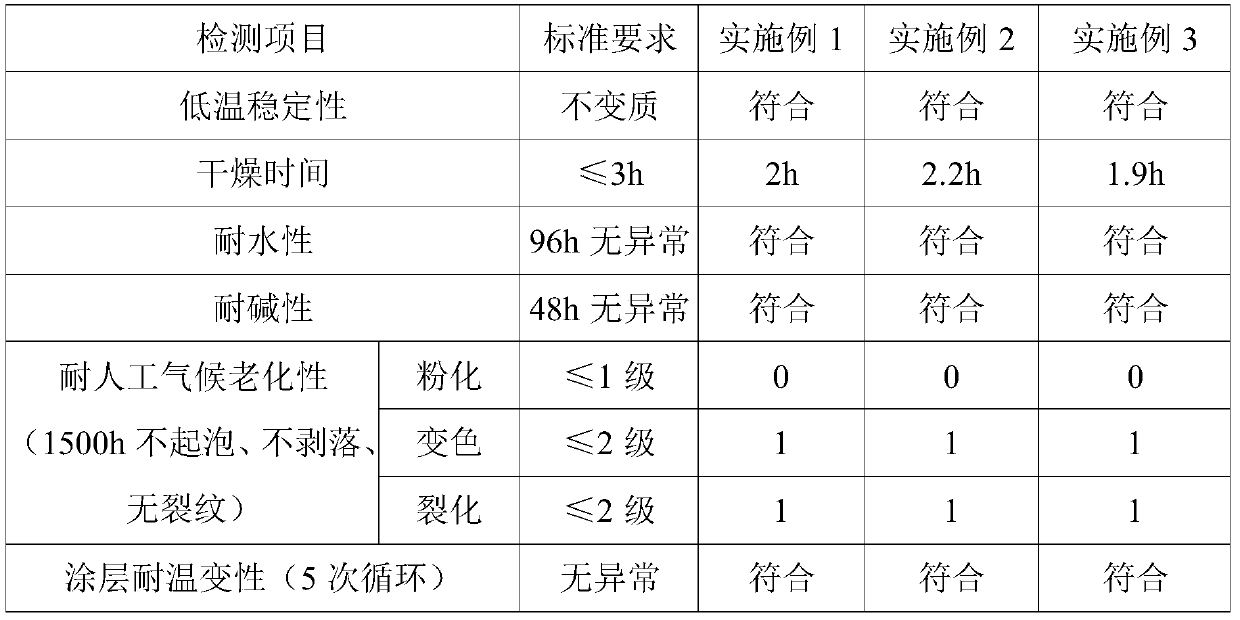

Embodiment 1

[0019] A kind of outdoor water-based anticorrosion finish paint raw material of the present embodiment is as follows:

[0020] Polyvinyl alcohol 220kg, water-based acrylic resin 400kg, water-based epoxy resin 150kg, distilled water 300kg, low-molecular-weight polyamide 200kg, water-based polyurethane curing agent 70kg, dispersant sodium dodecylbenzenesulfonate 35kg, anti-mold agent dodecane Dimethyl benzyl ammonium bromide 25kg, leveling agent organically modified polydimethylsiloxane 16kg, defoamer water-based polysiloxane 12kg, flame retardant ammonium polyphosphate 25kg, ultraviolet absorber nano dioxide 14kg of cerium, 30kg of pigment titanium dioxide.

[0021] Its preparation method is as follows:

[0022] 1. Add 220kg of distilled water into the stirred reactor, heat up to 46°C, add polyvinyl alcohol, heat while stirring, control the temperature in the kettle at 92°C, keep stirring for 0.5h, so that the polyvinyl alcohol is completely dissolved. Then add water-based ac...

Embodiment 2

[0026] A kind of outdoor water-based anticorrosion finish paint raw material of the present embodiment is as follows:

[0027] Polyvinyl alcohol 210kg, water-based acrylic resin 420kg, water-based epoxy resin 140kg, distilled water 320kg, low-molecular-weight polyamide 190kg, water-based polyurethane curing agent 72kg, dispersant sodium dodecylbenzenesulfonate 34kg, anti-mold agent dodecane Dimethyl benzyl ammonium bromide 23kg, leveling agent organically modified polydimethylsiloxane 17kg, defoamer water-based polysiloxane 13kg, flame retardant ammonium polyphosphate 23kg, ultraviolet absorber nano dioxide Cerium 15kg, pigment iron oxide red 35kg.

[0028] Its preparation method is as follows:

[0029] 1. Add 230kg of distilled water into the stirred reactor, heat up to 48°C, add polyvinyl alcohol, heat while stirring, control the temperature in the kettle at 93°C, keep stirring for 0.5h to dissolve the polyvinyl alcohol. Then add water-based acrylic resin and water-based e...

Embodiment 3

[0033] A kind of outdoor water-based anticorrosion finish paint raw material of the present embodiment is as follows:

[0034] 230kg of polyvinyl alcohol, 380kg of water-based acrylic resin, 170kg of water-based epoxy resin, 330kg of distilled water, 210kg of low molecular weight polyamide, 68kg of water-based polyurethane curing agent, 38kg of dispersant sodium dodecylbenzenesulfonate, and antifungal agent dodecane Dimethyl benzyl ammonium bromide 26kg, leveling agent organically modified polydimethylsiloxane 15kg, defoamer water-based polysiloxane 11kg, flame retardant ammonium polyphosphate 26kg, ultraviolet absorber nano dioxide Cerium 16kg, pigment phthalocyanine blue 38kg.

[0035] Its preparation method is as follows:

[0036] 1. Add 240kg of distilled water into the stirred reactor, heat up to 48°C, add polyvinyl alcohol, heat while stirring, control the temperature in the kettle at 91°C, keep stirring for 0.5h to dissolve the polyvinyl alcohol. Then add water-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com