Preparation method and application of complex microbial agent for straw degradation

A technology of composite bacterial agent and straw, applied in the direction of microorganism-based methods, biochemical equipment and methods, applications, etc., can solve the problems of poor treatment effect of straw, unstable adaptability and reproduction of straw-decomposing bacteria, and achieve reduction Preparation cost, improvement of fertilizer utilization rate, effect of activating potential nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

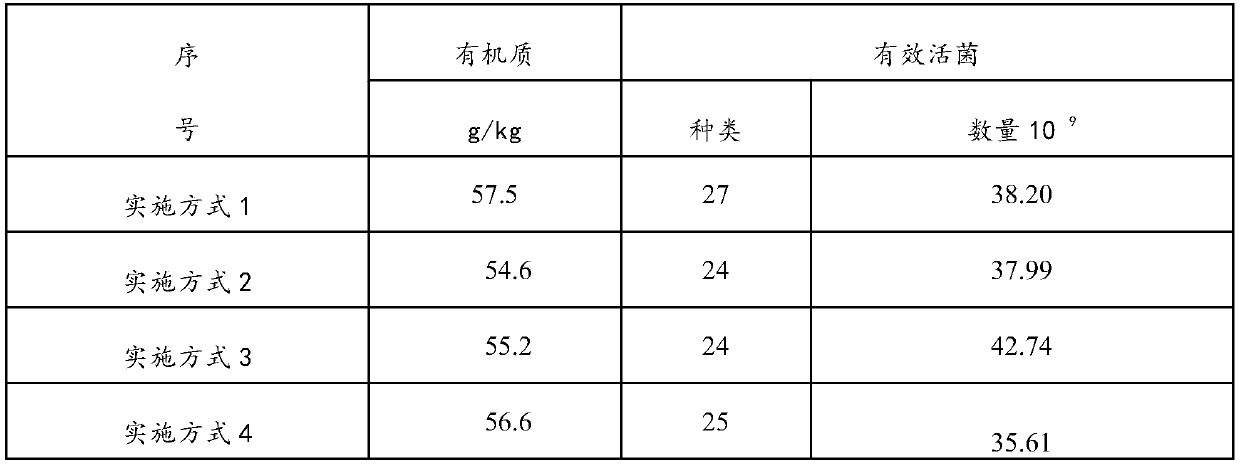

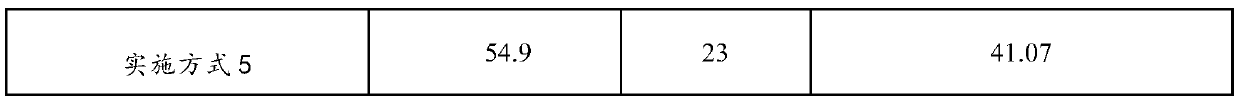

Examples

Embodiment approach 1

[0044] This embodiment provides a method for preparing a straw-degrading composite microbial agent, which includes the following steps:

[0045] S1 collects vegetable stalks and cuts them into sections to obtain straw waste A with a length of ≤2 cm;

[0046] S2 mix the straw waste A obtained in step 1, cultivated soil, decomposed sheep manure, lemon peel and water evenly to obtain a mixture B with a water content of 60%, wherein the mass ratio of straw waste A, cultivated soil and decomposed sheep manure The ratio is 2:1:2, the culture soil is soil with an organic matter content of 1.75%, no pests and diseases, and a granular structure, and the lemon peel is 0.2%-2% of the mass of the straw waste A;

[0047]S3 gets the mixture B obtained in step 2 of 100 parts by weight, and inoculates 1 part by weight of EM bacterium liquid, 1 part by weight of saccharomyces liquid, 1 part by weight of Bacillus subtilis bacterium liquid and 0.5 Trichoderma harzianum bacterium liquid of weigh...

Embodiment approach 2

[0051] This embodiment provides a method for preparing a straw-degrading composite microbial agent, which includes the following steps:

[0052] S1 collects vegetable stalks and cuts them into sections to obtain straw waste A with a length of ≤2 cm;

[0053] S2 Mix the straw waste A, cultivated soil, decomposed duck manure, orange peel and water obtained in step 1 to obtain a mixture B with a water content of 70%, wherein the mass ratio of straw waste A, cultivated soil and decomposed duck manure 1.8:0.8:2.2, the culture soil is soil with an organic matter content of 1.82%, no pests and diseases, and a granular structure, and the orange peel is 1.8% of the mass of the straw waste A;

[0054] S3 gets the mixture B obtained in step 2 of 100 parts by weight, and inoculates 0.8 parts by weight of EM bacterium liquid, 0.8 parts by weight of saccharomyces liquid, 1.2 parts by weight of Bacillus subtilis bacterium liquid and 0.65 Trichoderma harzianum bacterium liquid of weight part...

Embodiment approach 3

[0058] This embodiment provides a method for preparing a straw-degrading composite microbial agent, which includes the following steps:

[0059] S1 collects vegetable stalks and cuts them into sections to obtain straw waste A with a length of ≤2 cm;

[0060] S2 mix the straw waste A, cultivated soil, decomposed chicken manure, pomelo peel and water obtained in step 1 to obtain a mixture B with a water content of 50%, wherein the mass ratio of straw waste A, cultivated soil and decomposed chicken manure The ratio is 2.2:1.2:2, the culture soil is soil with an organic matter content of 1.68%, no pests and diseases, and a granular structure, and the pomelo peel is 1.2% of the mass of the straw waste A;

[0061] S3 takes 100 parts by weight of the mixture B obtained in step 2, and inoculates 1.2 parts by weight of EM bacterium liquid, 1 part by weight of saccharomyces liquid, 1 part by weight of Bacillus subtilis bacterium liquid and 0.35 Trichoderma harzianum bacterium liquid of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com