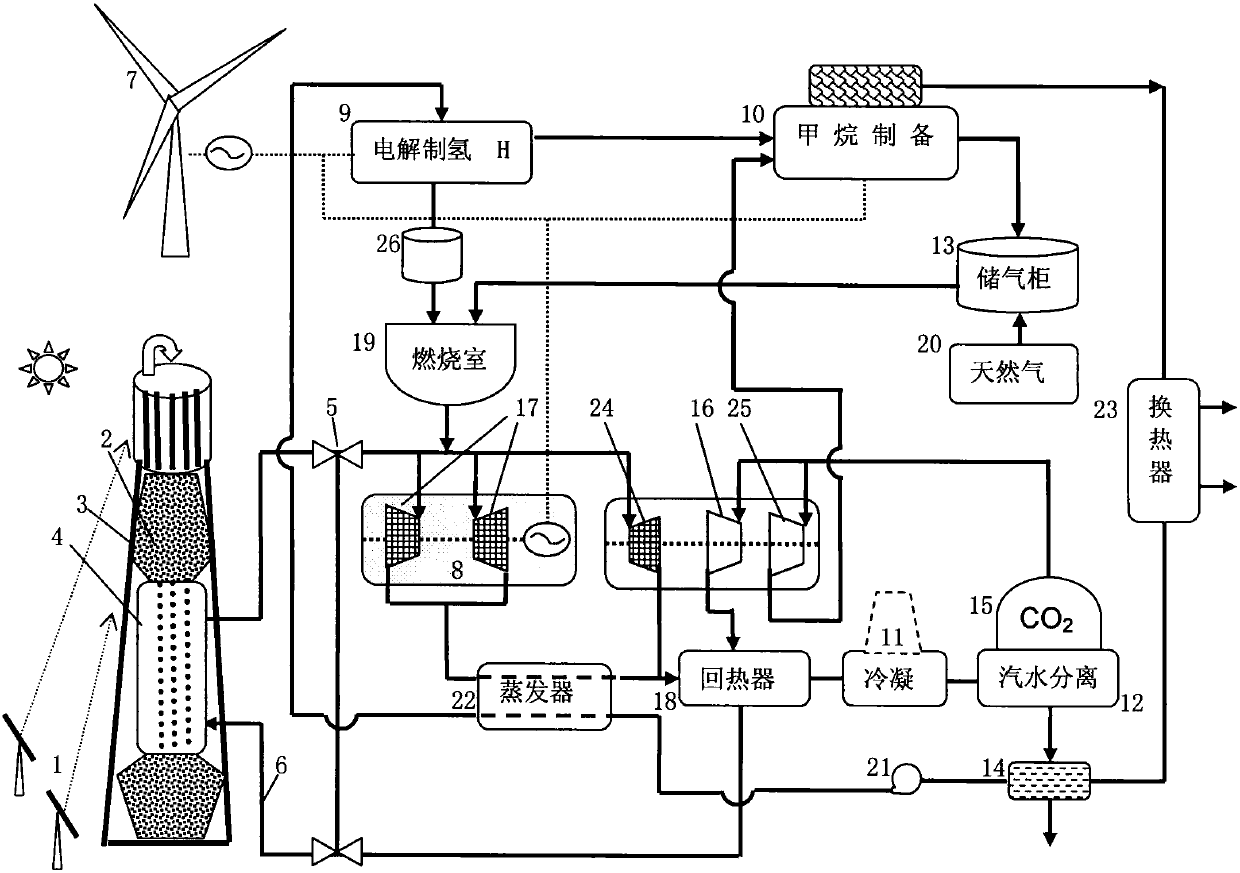

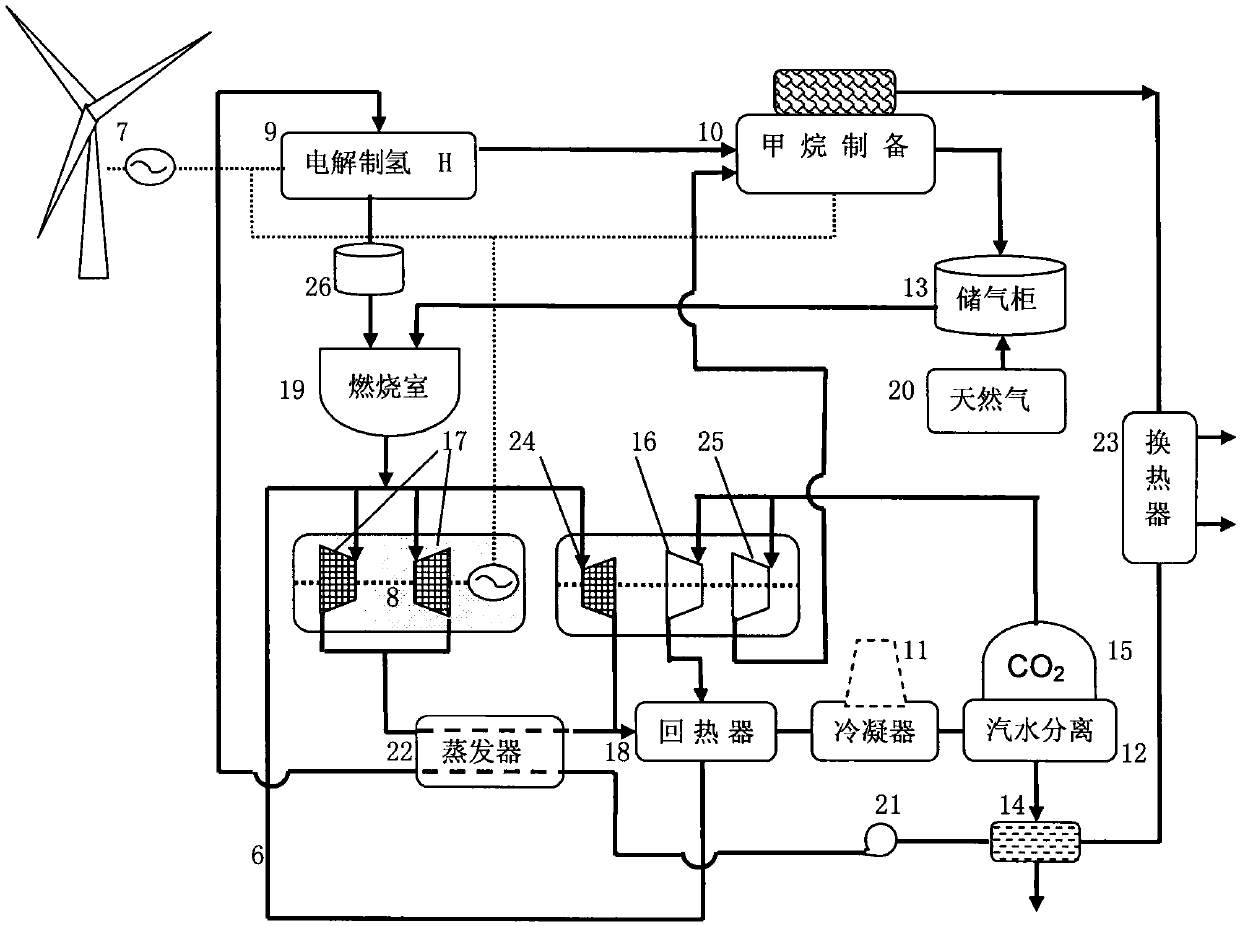

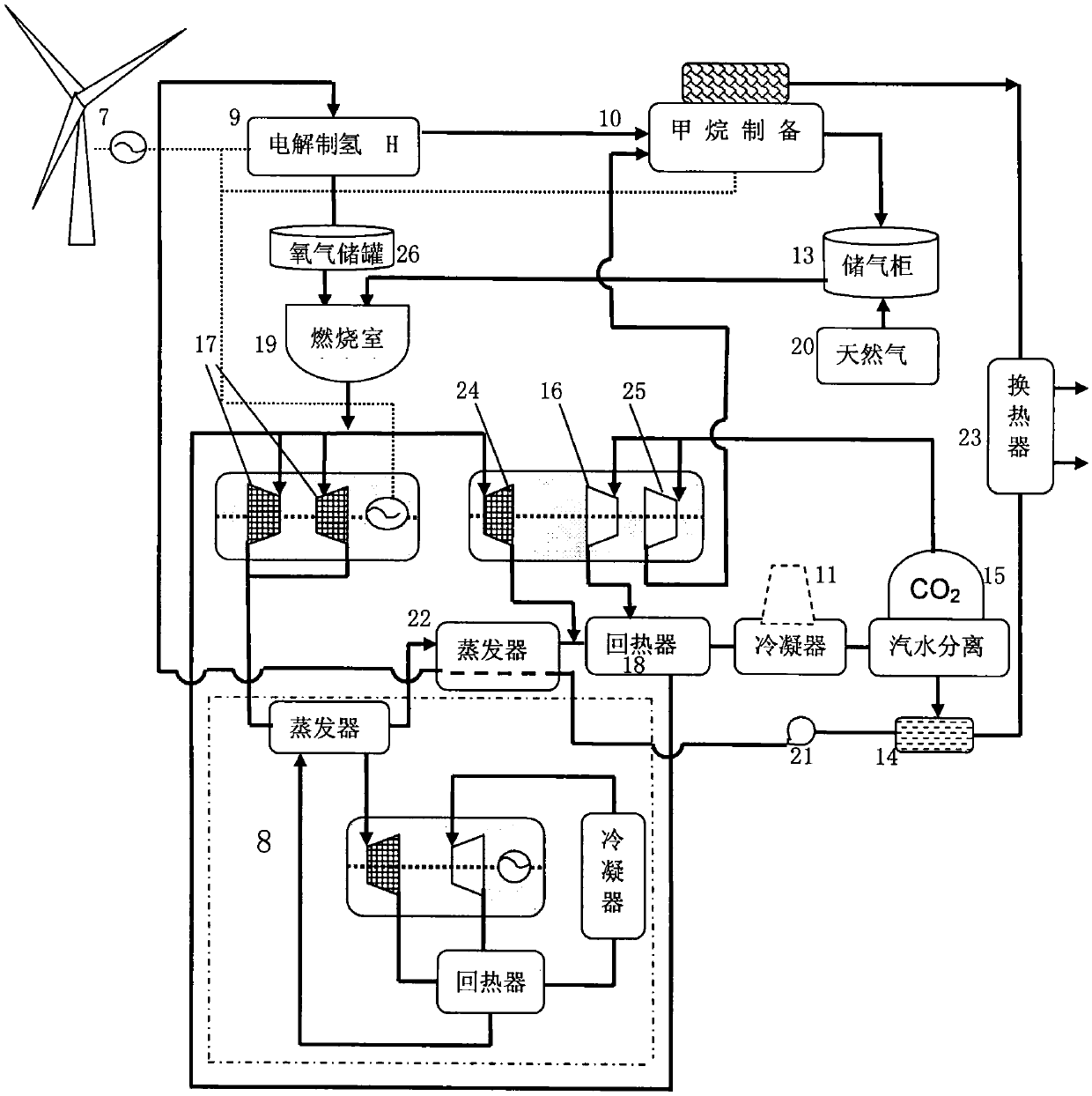

Solar energy, wind energy and fuel gas complementary combined hydrogen production methane production circulating thermal power generation device

A technology for hydrogen production and thermal power generation, which is applied in solar thermal power generation, wind power generation, gas turbine installations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The pressurized carbon dioxide gas from the carbon dioxide gas bag 15 enters the solid particle fluidized bed heat exchanger 4 of the tower solar solid particle concentrating system 1 through the heat transfer pipe for high-temperature heat exchange, and the supercritical carbon dioxide gas after high-temperature heat exchange passes through the The three-way valve 5 and the high-temperature gas mixed with natural gas and oxygen from the combustion chamber 19 enter the main turbine 17 to do work and the auxiliary turbine 24 drives the main and auxiliary compressors 16 and 25 to operate; The mixed gas enters the condenser 11 through the regenerator 18, the mixture produced by condensation enters the steam-water separator 12, the separated water enters the water storage tank 14, and the separated carbon dioxide enters the main compressor 16 and the auxiliary compressor 25 respectively. The carbon dioxide gas whose pressure has been raised by the main compressor 16 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com