Preparation method of secondary battery

A secondary battery, battery technology, applied in secondary batteries, secondary battery repair/maintenance, electrolyte battery manufacturing, etc., can solve the problems of limited battery charge and discharge rate performance, poor electrode wettability, complex process, etc. The effect of safety performance and electrochemical performance, low cost, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

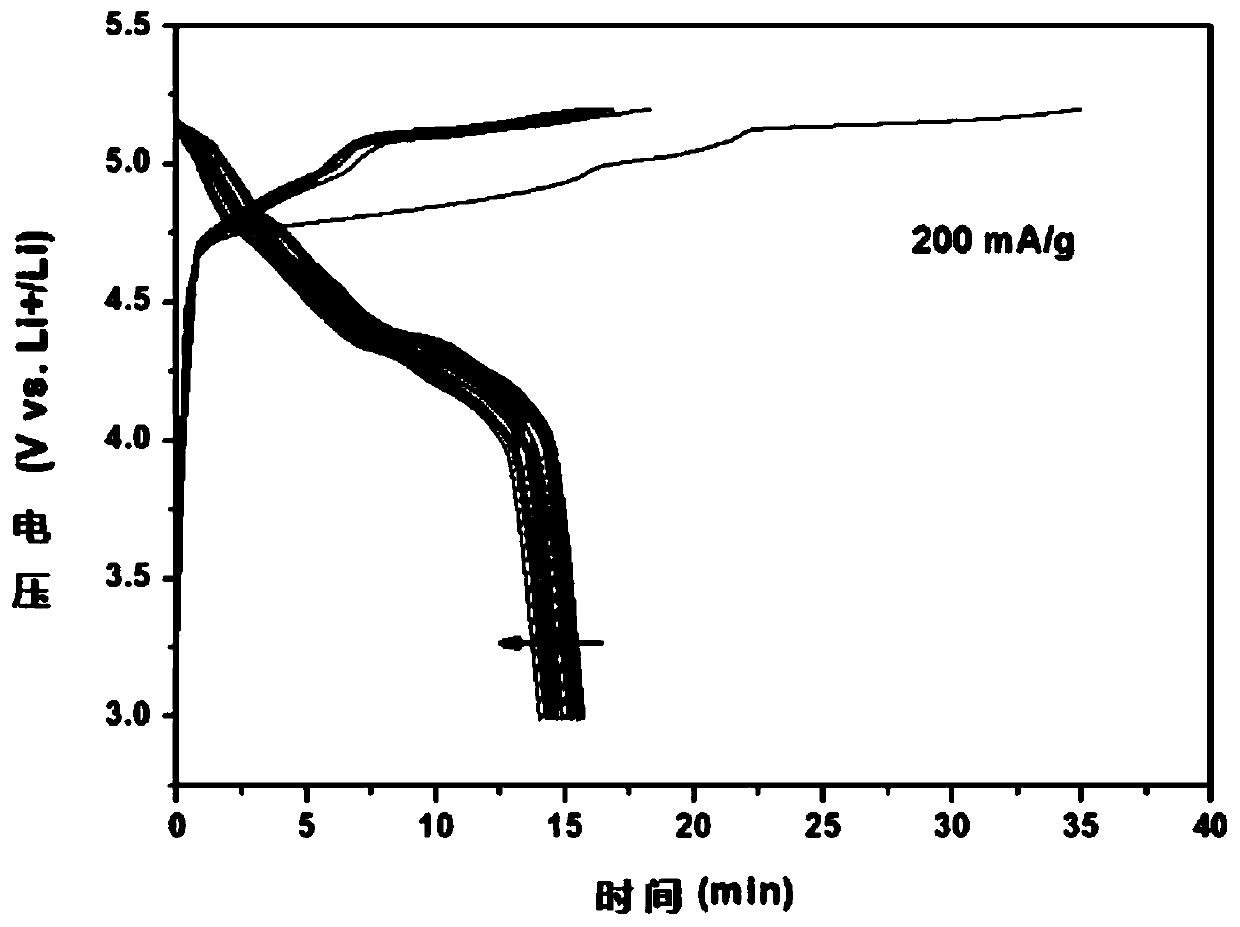

Image

Examples

preparation example Construction

[0027] A method for preparing a secondary battery, comprising the steps of:

[0028] S01. Assemble the first positive electrode sheet with the first separator, the first negative electrode sheet, the first electrolyte, and the first packaging case to prepare a first battery; the first positive electrode sheet includes a first positive electrode material and a first positive electrode assembly A fluid, the first electrolyte can surface passivate the first positive current collector during the charge-discharge cycle of the first battery;

[0029] S02. Perform a charge-discharge cycle on the first battery, and perform surface passivation treatment on the first positive electrode sheet, so that a passivation layer is formed on the surface of the first positive electrode current collector; then, disassemble the first battery , taking out the first positive electrode sheet that has undergone surface passivation treatment;

[0030] S03. Obtain a second positive electrode sheet, the ...

Embodiment approach

[0033]Specifically, the secondary battery refers to a type of battery that can activate active materials through charging and continue to be used. As an embodiment, the secondary battery is preferably a lithium ion battery, a sodium ion battery, a potassium ion battery, a magnesium ion battery, a calcium ion battery or a dual ion battery. In some embodiments, the secondary battery is a lithium ion battery. Further, the structure of the secondary battery can refer to the conventional battery structure in the field, which is mainly composed of a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and a packaging case.

[0034] In step S01, the first positive electrode sheet includes a first positive electrode material and a first positive electrode current collector. The first positive electrode material refers to conventional positive electrode materials in the field, and may be a commercial positive electrode material, or other Commonly used cat...

Embodiment 1

[0057] This embodiment provides a lithium ion battery, and its specific preparation process includes the following steps:

[0058] 1. Preparation of the first battery

[0059] 1) Lithium cobaltate, polyvinylidene fluoride (PVDF) and conductive carbon black are mixed evenly in a mass ratio of 8:1:1, and a certain amount of methylpyrrolidone (NMP) is added to grind evenly to obtain the first positive electrode material and then, coating the first positive electrode material on the aluminum foil, drying, and slicing to prepare the first positive electrode sheet.

[0060] 2) Lithium hexafluorophosphate was weighed and added to a mixed solvent of ethylene carbonate and dimethyl carbonate (v / v=1:1) to prepare a lithium hexafluorophosphate solution with a concentration of 1M as the first electrolyte.

[0061] 3) In the glove box, closely stack the first negative electrode sheet 4, metal lithium sheet, first separator 3, and first positive electrode sheet 2 in sequence, place them on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com