Functional probiotic solid beverage and preparation method thereof

A technology for functional probiotics and solid beverages, applied in the functions of food ingredients, bacteria and lactobacilli used in food preparation, etc., can solve the problem of no combination of lactic acid bacteria and solid beverage products, etc. The effect of improving human immunity, improving intestinal value rate and survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

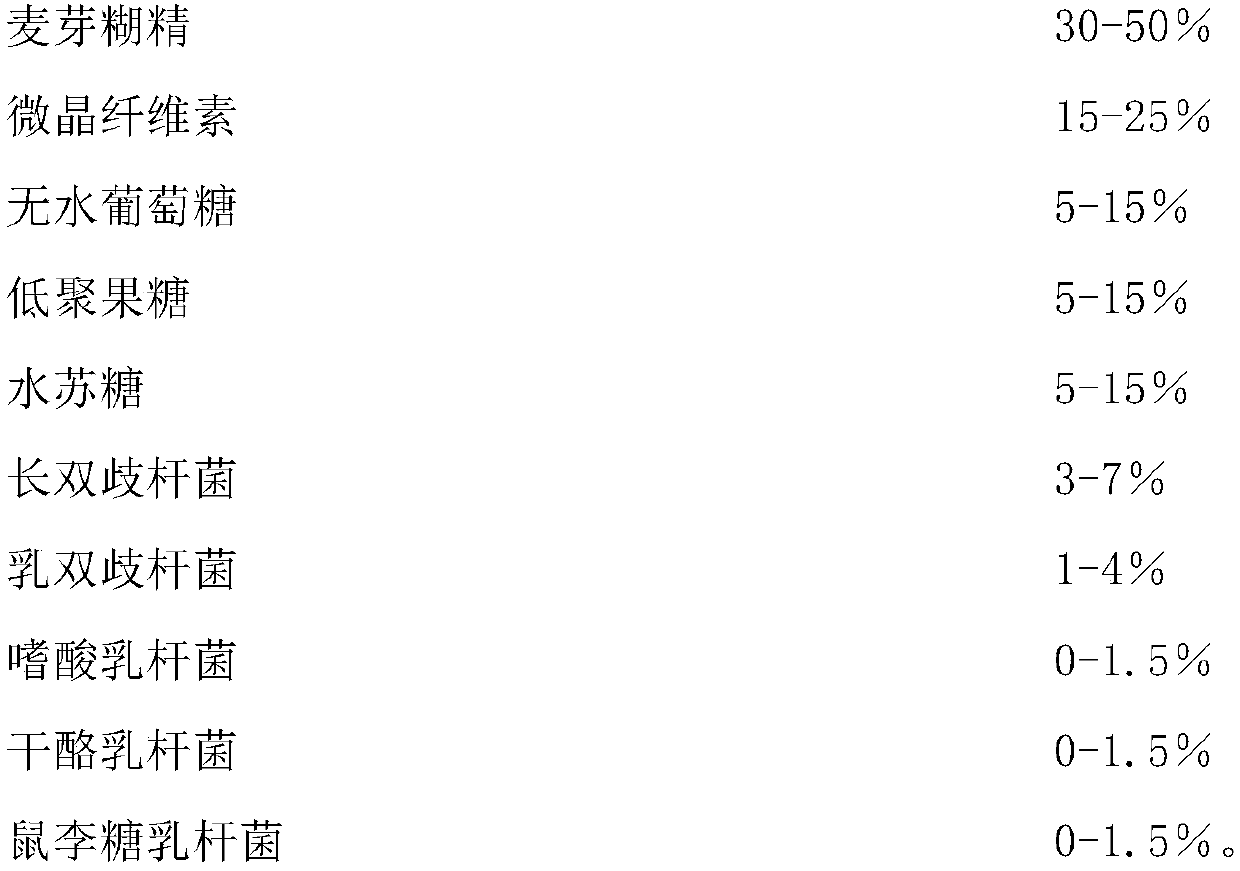

Embodiment 1

[0021] Embodiment 1: The present invention provides a functional probiotic solid beverage with the functions of each component: maltodextrin, also known as water-soluble dextrin or enzymatic dextrin, uses various starches as raw materials, and is processed by enzymatic method The process is low-level controlled hydrolysis conversion, purification, and drying. Its raw materials are starchy corn, rice, etc.; the main component of the microcrystalline cellulose is linear polysaccharides bound by β-1,4-glucosidic bonds, and the degree of polymerization is about 3000-10000 Glucose molecules, in general plant fibers, microcrystalline cellulose accounts for about 73%, and the other 30% is amorphous cellulose; anhydrous glucose is an organic compound, that is, glucose without crystal water, which is colorless crystal or white crystal Powder, odorless, sweet taste; soluble in water, slightly soluble in ethanol, anhydrous glucose is a nutritional medicine, can be used to make glucose in...

Embodiment 2

[0030] Embodiment 2 is compared with above-mentioned embodiment, and raw material and preparation method are identical, difference is, the proportioning that raw material is used: comprise the following steps:

[0031] S21: selecting raw materials for mashing, and screening through 80 meshes to obtain suitable raw materials;

[0032] S22: Prepare the raw materials obtained in step S1 according to mass percentage, the mass percentage is: 55% maltodextrin, 15% microcrystalline cellulose, 7% anhydrous glucose, 8% fructooligosaccharide, 8% stachyose, Bifidobacterium 4%, Bifidobacterium lactis 1%, Lactobacillus acidophilus 0.7%, Lactobacillus casei 0.7%, Lactobacillus rhamnosus 0.6%;

[0033] S23: The powder obtained in step S1 is mixed and packaged.

Embodiment 3

[0035] Embodiment 3 is compared with above-mentioned embodiment, and raw material and preparation method are identical, and difference is, the proportioning that raw material is used: comprise the following steps:

[0036] S31: selecting raw materials for mashing, and screening through 80 meshes to obtain suitable raw materials;

[0037] S32: Prepare the raw materials obtained in step S1 according to mass percentage, the mass percentage is: 30% maltodextrin, 21% microcrystalline cellulose, 12% anhydrous glucose, 13% fructooligosaccharide, 12% stachyose, Bifidobacterium 6%, Bifidobacterium lactis 2.5%, Lactobacillus acidophilus 1.5%, Lactobacillus casei 1.2%, Lactobacillus rhamnosus 1.3%;

[0038] S33: The powder obtained in step S1 is mixed and packaged.

[0039] The present invention is to use multiple probiotics (Bifidobacterium longum, Bifidobacterium lactis, Lactobacillus acidophilus, Lactobacillus casei, Lactobacillus rhamnosus) in combination, the product has good stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com