Temperature-sensitive acid liquid thickening agent for acid fracturing and preparation method thereof

An acid thickener and acid fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high initial viscosity, long dissolution time, high construction cost, etc., and achieve low fluid loss, The effect of low price and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

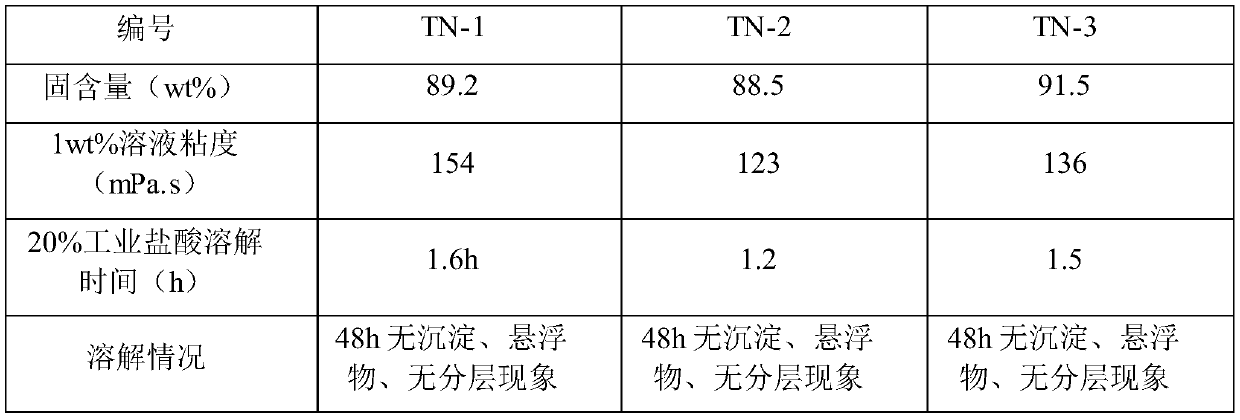

Examples

Embodiment 1

[0030] The present invention is a temperature-sensitive acid thickener for acid fracturing, which is prepared through the following steps:

[0031] 1) Use AM, vinyl chitooligosaccharide, sodium 2-methyl-2-acrylamidopropanesulfonate and diacetone acrylamide as comonomers, and the molar ratio of the four monomers is AM: vinyl chitooligosaccharide Sugar (50% cationic degree): sodium 2-methyl-2-acrylamidopropanesulfonate: diacetone acrylamide = 100: 10: 2.5: 3.5, add the four monomers into water and stir to dissolve;

[0032] 2) Adjust the reaction system to 25°C, adjust the pH value of the system to 6.8, blow in high-purity nitrogen for 20 minutes, and then add an initiator accounting for 0.05% of the total monomer mass to initiate polymerization;

[0033] 3) The polymerization reaction is carried out under heat preservation and airtight conditions. When the reaction system reaches the highest temperature, the reaction is continued for 2 hours, and then the colloid is taken out f...

Embodiment 2

[0036] The present invention is a temperature-sensitive acid thickener for acid fracturing, which is prepared through the following steps:

[0037] 1) Use AM, vinyl chitooligosaccharide, sodium vinylbenzene sulfonate and dodecylphenol polyoxyethylene ether (18) acrylate as comonomers, and the feeding mole of the four monomers is AM: vinyl shell Polysaccharide (85% cationic degree): sodium vinylbenzene sulfonate: dodecylphenol polyoxyethylene ether (20) acrylate = 100:1:4:3, add the four monomers into water and stir to dissolve;

[0038] 2) Adjust the reaction system to 50°C, adjust the pH value of the system to 7.6, blow in high-purity nitrogen for 20 minutes, and then add an initiator accounting for 0.03% of the total monomer mass to initiate polymerization;

[0039] 3) The polymerization reaction is carried out under heat preservation and airtight conditions. When the reaction system reaches the highest temperature, the reaction is continued for 2 hours, and then the colloid...

Embodiment 3

[0042] The present invention is a temperature-sensitive acid thickener for acid fracturing, which is prepared through the following steps:

[0043] 1) Use AM, vinyl chitosan, sodium vinyl sulfonate and dodecylphenol polyoxyethylene ether (18) acrylate as comonomers, and the feeding mole of the four monomers is AM: vinyl chitosan Sugar (65% cationic degree): sodium vinyl sulfonate: dodecylphenol polyoxyethylene ether (20) acrylate = 100: 2.6: 2: 5, add the four monomers into water and stir to dissolve;

[0044] 2) Adjust the reaction system to 30°C, adjust the pH value of the system to 7, blow in high-purity nitrogen for 20 minutes, and then add an initiator accounting for 0.02% of the total monomer mass to initiate polymerization;

[0045] 3) The polymerization reaction is carried out under heat preservation and airtight conditions. When the reaction system reaches the highest temperature, the reaction is continued for 2 hours, and then the colloid is taken out for granulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com