Biomass-based sodium ion battery hard carbon anode material, and preparation method and application thereof

A sodium-ion battery, biomass material technology, applied in active material electrodes, battery electrodes, carbon preparation/purification, etc., can solve the problems of low specific capacity, difficult to effectively store sodium, etc., achieve excellent electrochemical performance, raw materials low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment is used to illustrate the preparation method of a kind of biomass-based sodium ion battery hard carbon negative electrode material of the present invention, comprises the following steps:

[0058] 1) 1000 g of corn stalks were used as raw materials, washed three times with deionized water, and then dried in a muffle furnace at 100° C. for 5 hours.

[0059] 2) The corn stover obtained in step 1) was heated at 800° C. for 4 hours in an oxygen-deficient atmosphere to obtain a preliminary pyrolyzed carbon precursor.

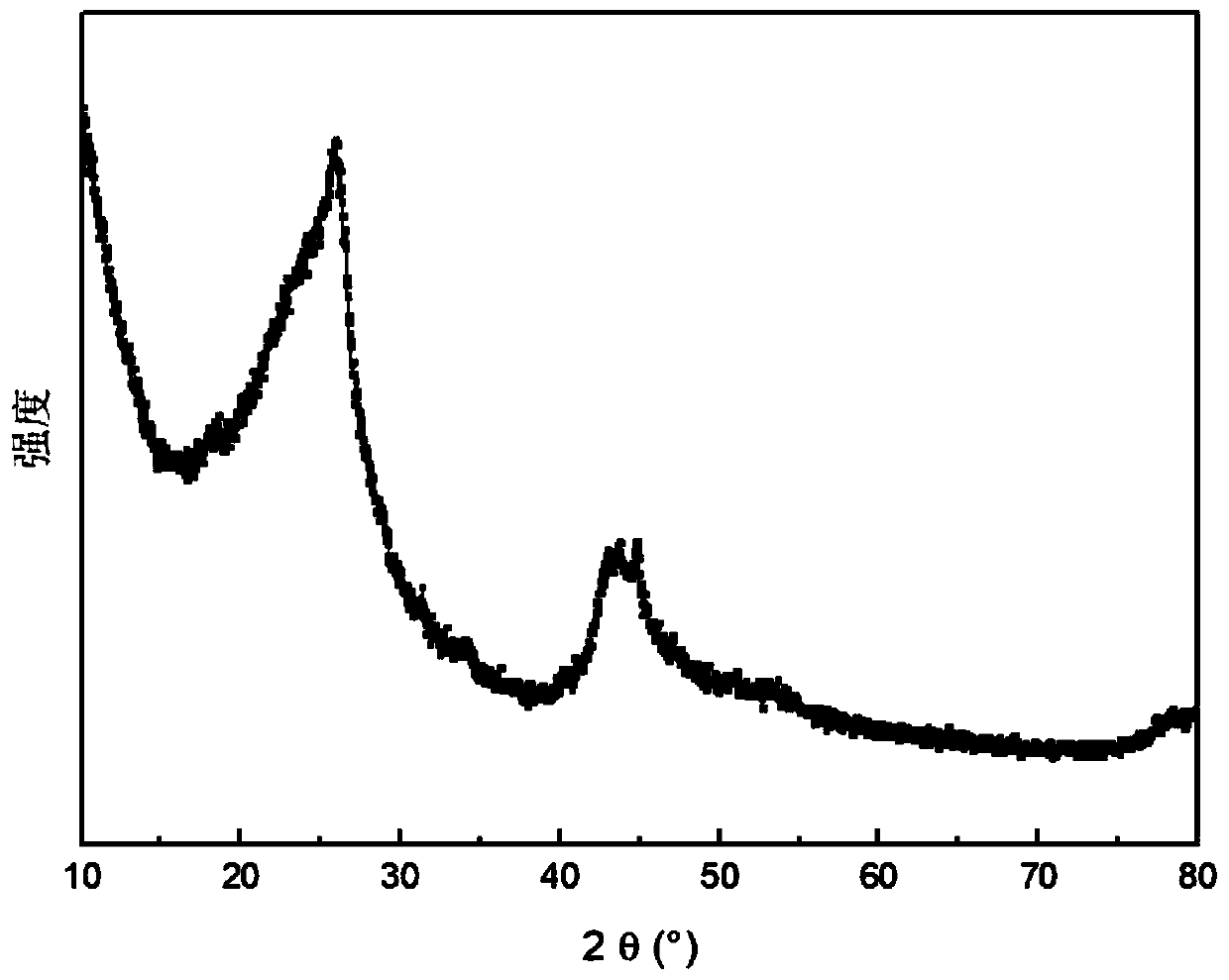

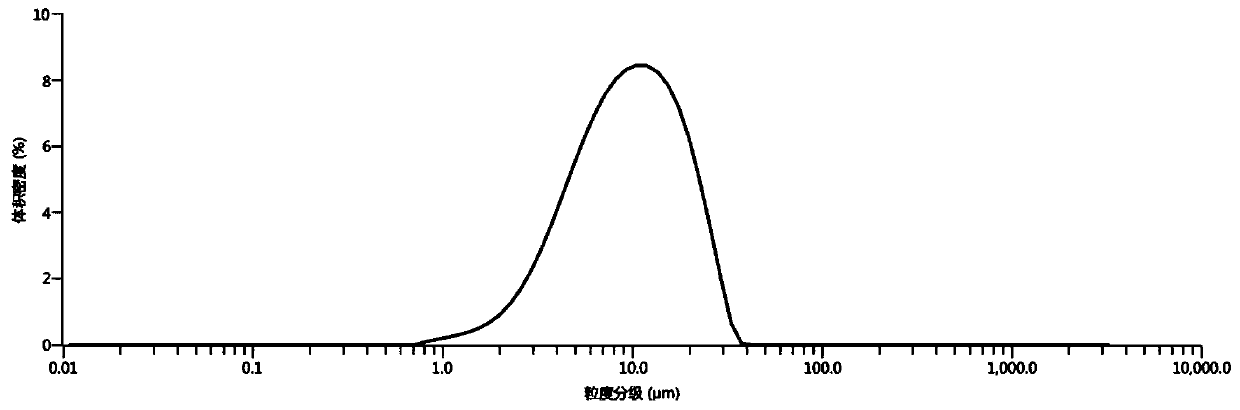

[0060] 3) The carbon precursor obtained in step 2) is pulverized with a ball mill until D50 reaches 10 microns, and the particle size distribution is narrow.

[0061] 4) The pulverized carbon precursor was immersed in 1 L, 0.1 mol / L lithium permanganate solution and stirred for 1 hour, and then the carbon precursor was taken out.

[0062] 5) The treated carbon precursor is dried at 110° C. for 5 hours and passed through a 160-mesh sieve.

[0...

Embodiment 2

[0070] This embodiment is used to illustrate the preparation method of a kind of biomass-based sodium ion battery hard carbon negative electrode material of the present invention, comprises the following steps:

[0071] 1) Take 200 g of pumpkin vines as a raw material, wash with dedistilled water three times, and dry at 130° C. for 5 hours in a blast oven.

[0072] 2) The pumpkin vine obtained in step 1) was heated at 600° C. for 10 hours under an argon atmosphere to obtain a preliminary pyrolyzed carbon precursor.

[0073] 3) The carbon precursor obtained in step 2) is pulverized with a jet mill until the D50 reaches 20 microns, and the particle size distribution is narrow.

[0074] 4) The pulverized carbon precursor was immersed in 500 mL, 1 mol / L sodium permanganate solution and stirred for 1 hour, and then the carbon precursor was taken out.

[0075] 5) Dry the treated carbon precursor at 200° C. for 5 hours and pass through a 300-mesh sieve.

[0076] 6) The material was...

Embodiment 3

[0082] This embodiment is used to illustrate the preparation method of a kind of biomass-based sodium ion battery hard carbon negative electrode material of the present invention, comprises the following steps:

[0083] 1) 1000 g of rice straw was used as a raw material, washed three times with dedistilled water, and then dried in a tube furnace at 201° C. for 48 hours.

[0084] 2) Heating the straw obtained in step 1) at 300° C. for 24 hours under a helium atmosphere to obtain a preliminary pyrolyzed carbon precursor.

[0085] 3) The carbon precursor obtained in step 2) is crushed with a jaw crusher until the D50 reaches 50 microns, and the particle size distribution is narrow.

[0086] 4) The pulverized carbon precursor was immersed in 2L, 0.5 mol / L potassium permanganate solution and stirred for 1 hour, and then the carbon precursor was taken out.

[0087] 5) Dry the treated carbon precursor at 200° C. for 5 hours and pass through a 300-mesh sieve.

[0088] 6) The materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com