A kind of preparation method and application of sgo-zno-psf composite ultrafiltration membrane

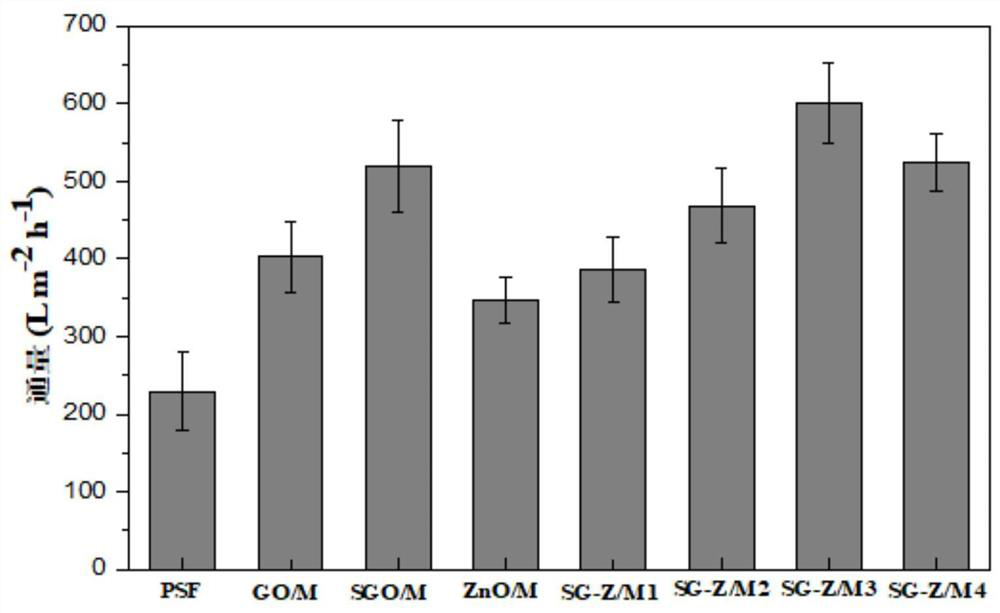

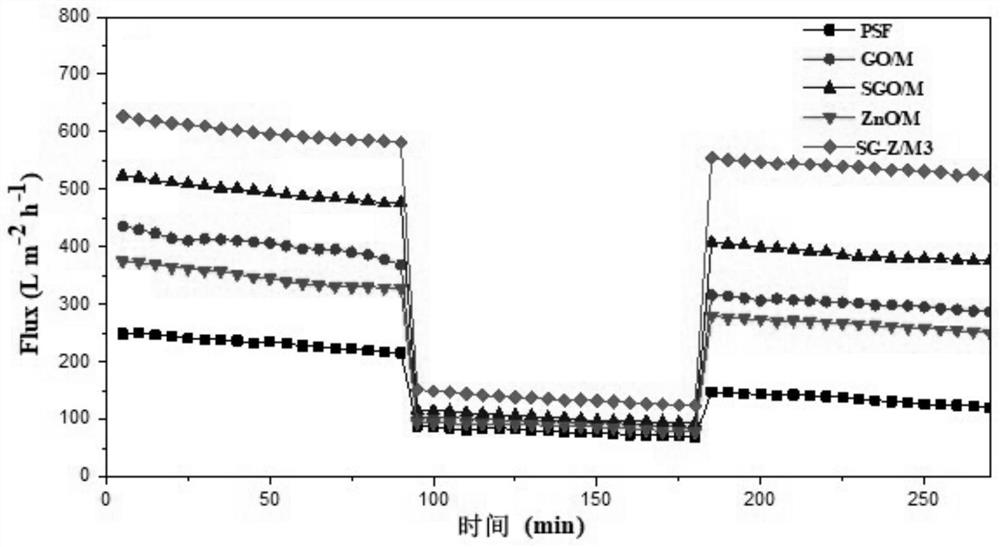

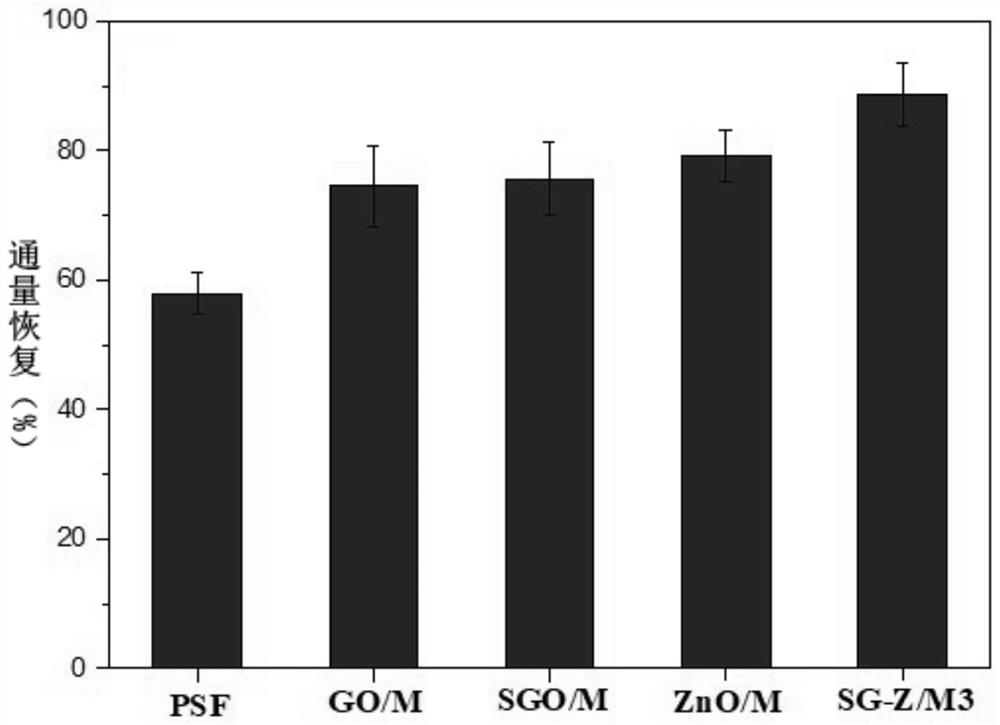

A technology of ultrafiltration membranes and composite nanomaterials, which is applied in the field of preparation of SGO-ZnO-PSF composite ultrafiltration membranes, can solve problems affecting membrane separation performance, achieve the effects of improving antifouling performance, large application value, and alleviating agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of SGO-ZnO composite nanomaterials: Add 2.0 g of anhydrous zinc acetate into 100 mL of absolute ethanol to form a zinc acetate / ethanol solution, reflux at 80 °C for 20 min and cool to 50 °C; , take 0.15 g SGO and disperse it in 50 mL absolute ethanol, add 0.3 g lithium hydroxide after ultrasonication for 30 min to obtain SGO / ethanol solution, stir in 50°C water bath for 30 min; then add SGO / ethanol solution to zinc acetate / In the ethanol solution, continue to stir in a 50°C water bath for 40min; after the mixed solution is naturally cooled to room temperature, add 200 mL of hexane, seal it, place it in the refrigerator overnight, centrifuge and wash with deionized water and ethanol three times respectively, and vacuum at 45°C Vacuum drying for 12 h to obtain SGO-ZnO composite nanomaterials.

[0033] (2) Preparation of SGO-ZnO-PSF composite ultrafiltration membrane: 0.01 g of the SGO-ZnO composite nanomaterial (0.05 wt.%) prepared in step (1) was dissolv...

Embodiment 2

[0036](1) Preparation of SGO-ZnO composite nanomaterials: Add 3.0 g of anhydrous zinc acetate into 100 mL of absolute ethanol to form a zinc acetate / ethanol solution, reflux at 80 °C for 20 min and cool to 50 °C; at the same time , take 0.2 g SGO and disperse it in 50 mL absolute ethanol, add 0.3 g lithium hydroxide after ultrasonication for 30 min to obtain SGO / ethanol solution, stir in 50 °C water bath for 30 min; then add SGO / ethanol solution to zinc acetate / A mixed solution was formed in the ethanol solution, and continued to stir in a water bath at 50°C for 40 min. After the mixed solution was naturally cooled to room temperature, 200 mL of hexane was added, sealed, placed in the refrigerator overnight, and then centrifuged and washed three times with deionized water and ethanol. , vacuum-dried at 45°C for 12 h to obtain SGO-ZnO composite nanomaterials.

[0037] (2) Preparation of SGO-ZnO-PSF composite ultrafiltration membrane: Take 0.02g of the SGO-ZnO composite nanomat...

Embodiment 3

[0040] (1) Preparation of SGO-ZnO composite nanomaterials: Take 1.0 g of anhydrous zinc acetate and add it to 100 mL of absolute ethanol to form a zinc acetate / ethanol solution, reflux at 80 °C for 20 min and then cool the temperature to 50 °C; , take 0.1 g SGO and disperse it in 50 mL absolute ethanol, add 0.3 g lithium hydroxide after ultrasonication for 30 min to obtain SGO / ethanol solution, stir in 50 °C water bath for 30 min; then add SGO / ethanol solution to zinc acetate / A mixed solution was formed in the ethanol solution, and continued to stir in a water bath at 50°C for 40 min. After the mixed solution was naturally cooled to room temperature, 200 mL of hexane was added, sealed, placed in the refrigerator overnight, and then centrifuged and washed three times with deionized water and ethanol. , vacuum-dried at 45°C for 12 h to obtain SGO-ZnO composite nanomaterials.

[0041] (2) Preparation of SGO-ZnO-PSF composite ultrafiltration membrane: 0.04 g of the SGO-ZnO compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com