Preparation method and application of PVDF (polyvinylidene fluoride)@PDA@ZnO composite membrane

A technology of composite membrane and membrane casting solution, which is applied in the direction of separation methods, chemical instruments and methods, membranes, etc., can solve the problems of water-removing membranes that are prone to pollution, etc., and achieve good UV self-cleaning properties, no secondary pollution, and structural stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 3g of polyvinylidene fluoride powder, 1g of polyethylene glycol, and 0.1g of polyvinylpyrrolidone into 30mL of N-methylpyrrolidone, mechanically stir at 50°C for 12 hours to obtain a casting solution, and pour the casting solution on the glass Scrape the plate evenly with a glass rod, slowly put it into deionized water, and make PVDF membrane by phase inversion method;

[0034] (2) Prepare 100 mL of 2 mg / L dopamine hydrochloride solution, add PVDF membrane, seal and shake for 6 hours, rinse with deionized water, and dry to prepare PVDF@PDA membrane;

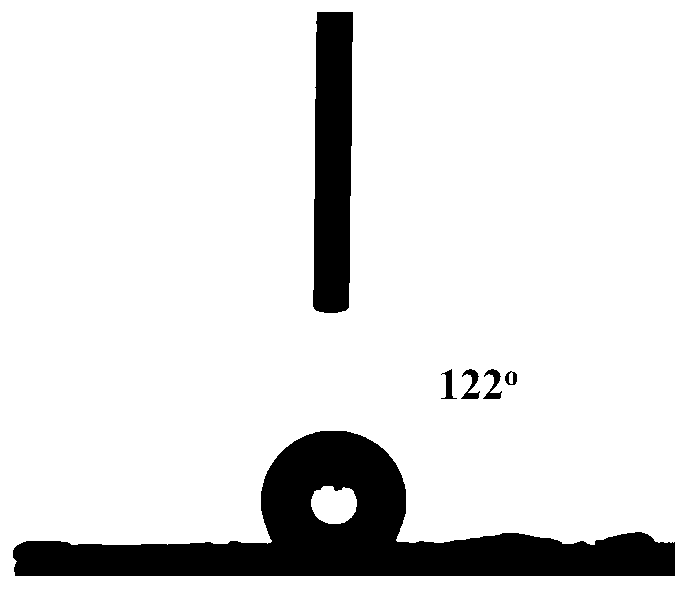

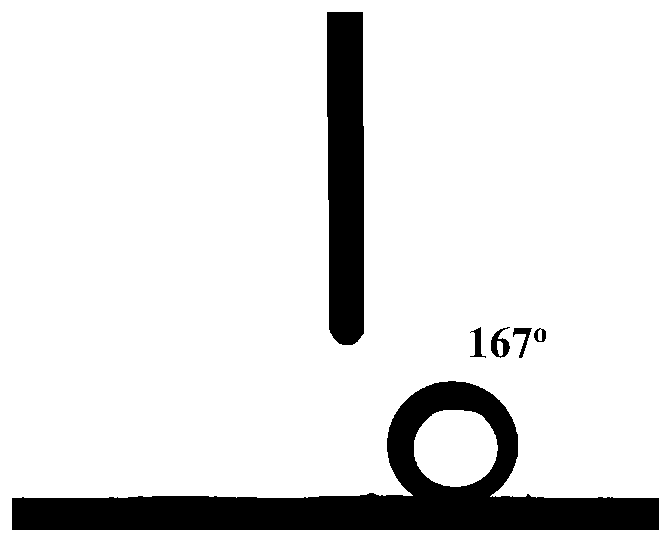

[0035] (3) Weigh 1.284g of anhydrous zinc acetate and 0.4g of sodium hydroxide to prepare a zinc acetate ethanol solution with a concentration of 70mmoL / L and a sodium hydroxide ethanol solution with a concentration of 0.1moL / L; weigh 1.19g of zinc nitrate and Dissolve 0.561g of cyclohexamethylenetetramine in 50mL of deionized water to make a mixed solution; put the PVDF@PDA membrane in the prepared zinc acetate et...

Embodiment 2

[0037] (1) Weigh 3g of polyvinylidene fluoride powder, 1g of polyethylene glycol, and 0.1g of polyvinylpyrrolidone into 30mL of N-methylpyrrolidone, stir mechanically at 50°C for 12 hours to obtain a casting solution, and pour the casting solution into Scrape the glass plate evenly with a glass rod, slowly put it into deionized water, and make PVDF membrane by phase inversion method;

[0038] (2) Prepare 100 mL of 2 mg / L dopamine hydrochloride solution, add PVDF membrane, seal and shake for 6 hours, rinse with deionized water, and dry to prepare PVDF@PDA membrane;

[0039](3) Weigh 1.284g of anhydrous zinc acetate and 0.4g of sodium hydroxide to prepare a zinc acetate ethanol solution with a concentration of 70mmoL / L and a sodium hydroxide ethanol solution with a concentration of 0.1moL / L; weigh 1.19g of zinc nitrate and Dissolve 0.561g of cyclohexamethylenetetramine in 50mL of deionized water to make a mixed solution; put the PVDF@PDA membrane in the prepared zinc acetate eth...

Embodiment 3

[0048] (1) Weigh 3g of polyvinylidene fluoride powder, 1g of polyethylene glycol, and 0.1g of polyvinylpyrrolidone into 30mL of N-methylpyrrolidone, stir mechanically at 50°C for 12 hours to obtain a casting solution, and pour the casting solution into Scrape the glass plate evenly with a glass rod, slowly put it into deionized water, and make PVDF membrane by phase inversion method;

[0049] (2) Prepare 100 mL of 2 mg / L dopamine hydrochloride solution, add PVDF membrane, seal and shake for 6 hours, rinse with deionized water, and dry to prepare PVDF@PDA membrane;

[0050] (3) Weigh 1.284g of anhydrous zinc acetate and 0.4g of sodium hydroxide to prepare a zinc acetate ethanol solution with a concentration of 70mmoL / L and a sodium hydroxide ethanol solution with a concentration of 0.1moL / L; weigh 1.19g of zinc nitrate and Dissolve 0.561g of cyclohexamethylenetetramine in 50mL of deionized water to make a mixed solution; put the PVDF@PDA membrane in the prepared zinc acetate et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com