Sr2FeTaO6 photocatalytic material as well as preparation method and application thereof

A photocatalytic material, tantalum pentachloride technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of low catalytic activity, high cost, reaction Higher equipment requirements and other issues, to achieve the effect of high catalytic activity, low cost, and easy control of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Sr 2 FeTaO 6 Preparation of denitrification catalyst materials and evaluation of catalytic denitrification

[0034] (1) Dissolve 7.5ml of oleic acid in 52.5ml of absolute ethanol, then add 300mg of sodium oleate, stir well to make it completely dissolve;

[0035] (2) Add 1.074g of tantalum pentachloride to the above solution, then add 1.059g of iron acetylacetonate and 1.234g of strontium acetate, and stir for about 12 hours to completely dissolve it;

[0036] (3) Add sodium hydroxide solution (8M), stir to dissolve, and the pH of the solution is 12 at this time.

[0037] (4) Add the solution to a hydrothermal kettle for hydrothermal reaction at 200°C, heat the reaction for 12 hours, rinse with absolute ethanol and water, and dry to obtain Sr 2 FeTaO6 Powder;

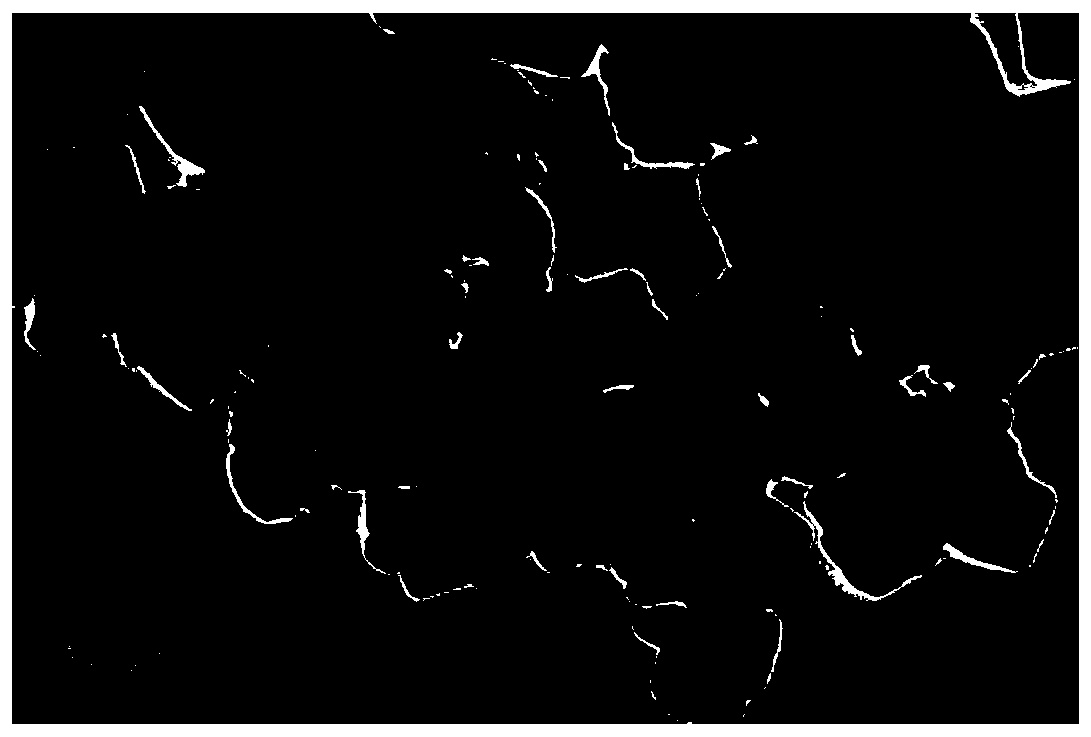

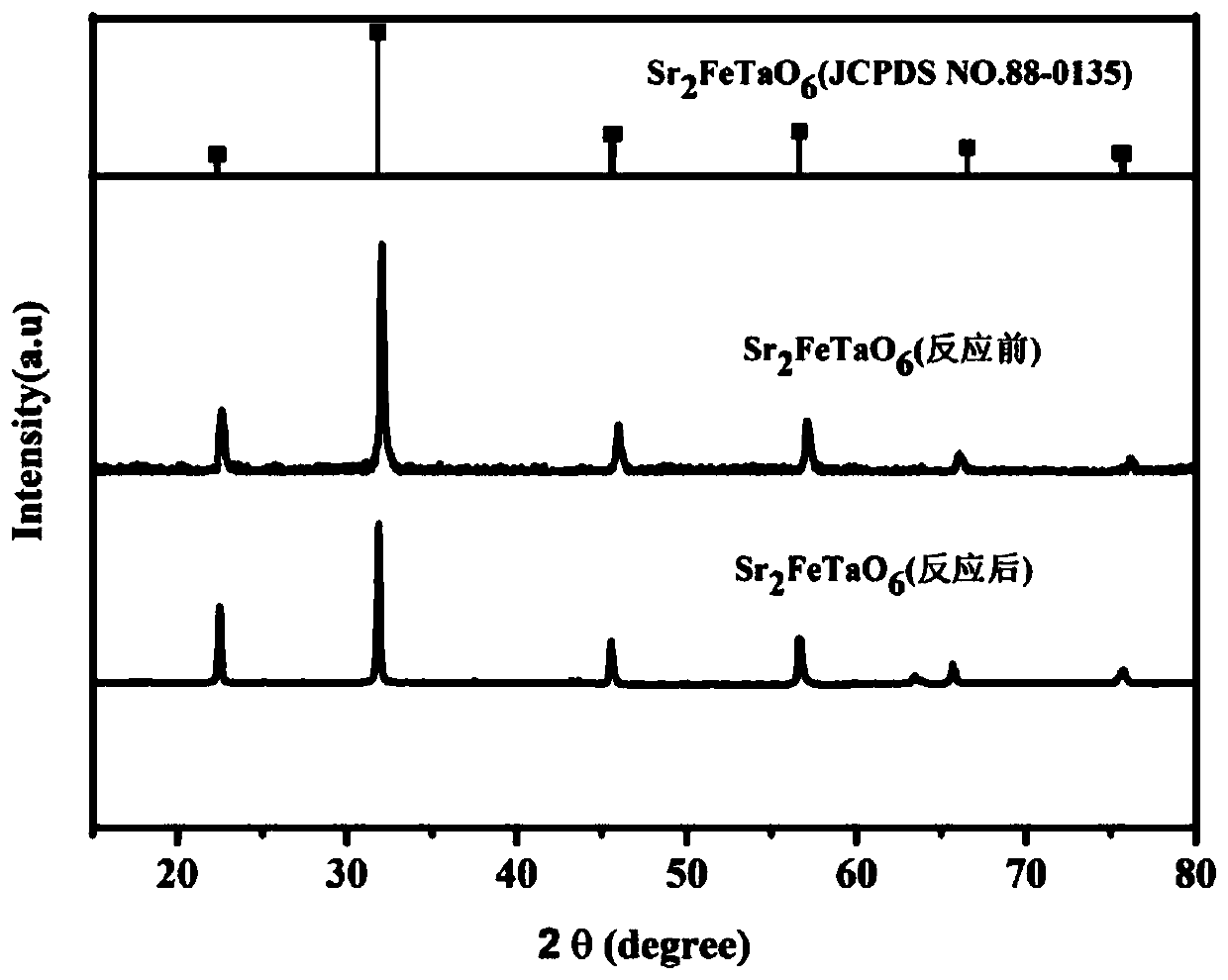

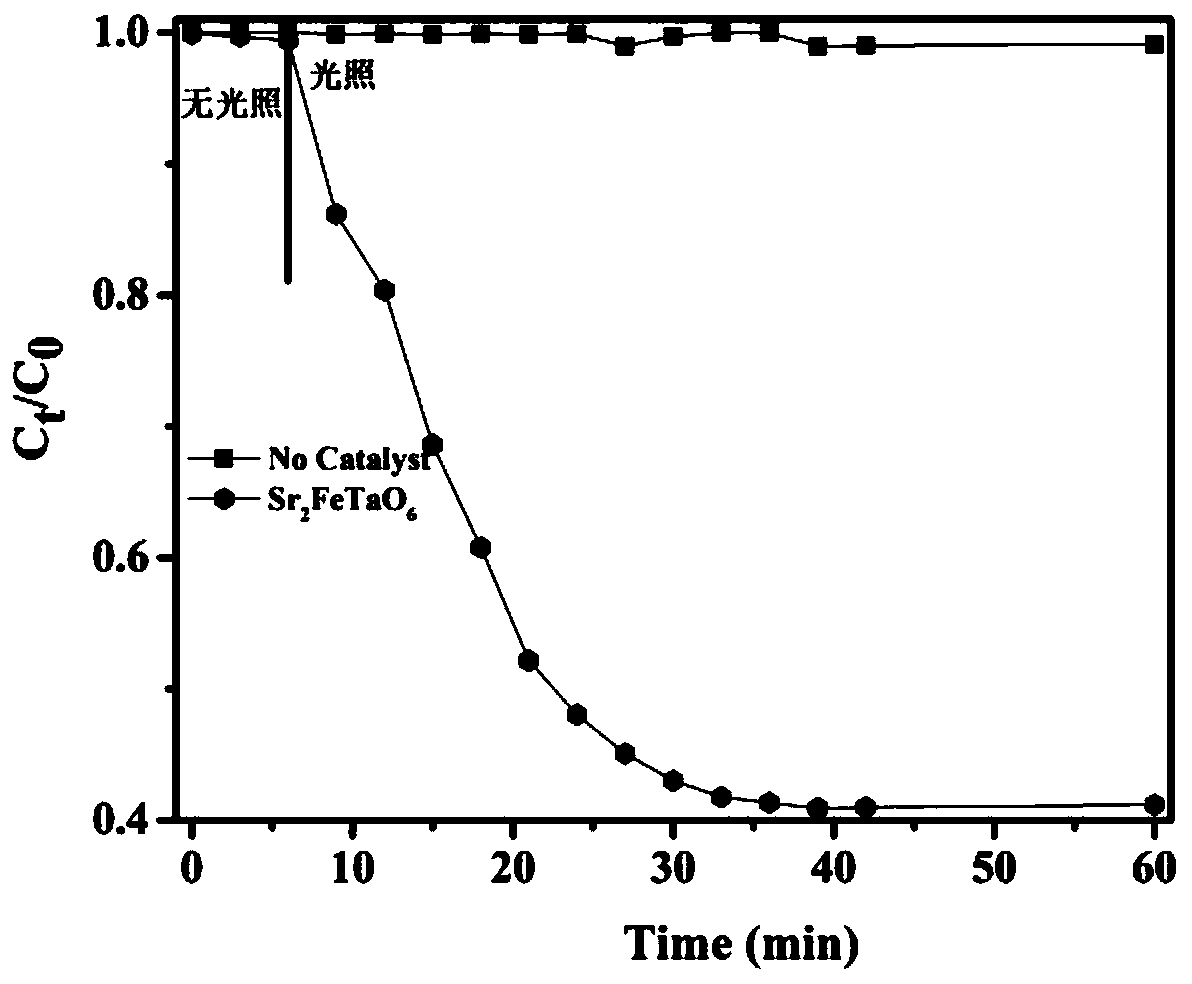

[0038] The Sr of its step (4) 2 FeTaO 6 The TEM and XRD images of the powder are as follows figure 1 and figure 2 as shown, figure 1 for Sr 2 FeTaO 6 topography of the material, figure 2 It shows th...

Embodiment 2

[0046] (1) Dissolve 17.5ml of oleic acid in 100mL of absolute ethanol, then add 500mg of sodium oleate, stir well to make it completely dissolve;

[0047] (2) Add 2.148g of tantalum pentachloride to the above solution, then add 2.118g of iron acetylacetonate and 1.234g of strontium acetate, and stir for about 12 hours to completely dissolve it;

[0048] (3) Add sodium hydroxide solution (8M) and stir to dissolve; the pH of the solution is now 14.

[0049] (4) Add the solution to a hydrothermal kettle for hydrothermal reaction at 200°C, heat the reaction for 12 hours, rinse with absolute ethanol and water, and dry to obtain Sr 2 FeTaO 6 Powder;

[0050] The conversion rate of NO measured in this embodiment is above 57.6%.

Embodiment 3

[0052] (1) Dissolve 5ml of oleic acid in 10mL of absolute ethanol, then add 200mg of sodium oleate, stir well to make it completely dissolve;

[0053] (2) Add 2.148g of tantalum pentachloride to the above solution, then add 1.059g of iron acetylacetonate and 1.234g of strontium acetate, and stir for about 12 hours to completely dissolve it;

[0054] (3) Add sodium hydroxide solution (8M) and stir to dissolve; at this time, the pH of the solution is 10.

[0055] (4) Add the solution to a high-pressure hydrothermal kettle for hydrothermal reaction at 200°C, heat the reaction for 12 hours, rinse with absolute ethanol and water, and dry to obtain Sr 2 FeTaO 6 Powder.

[0056] The conversion rate of NO measured in this embodiment is above 55.5%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com