Photoresponsive polymer gelling factor, photoresponsive gel and preparation method thereof

A gel factor and photoresponse technology, applied in the field of supramolecular materials, can solve problems such as slow response speed, poor mechanical properties, and complicated preparation methods, and achieve the effect of enhanced mechanical properties, excellent mechanical properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A photoresponsive gel provided in this embodiment includes 10wt% photoresponsive polymer gelling factor and 90wt% acetonitrile, wherein the structure of the photoresponsive polymer gelling factor is:

[0053]

[0054] In the structure of photoresponsive polymer gelling factor is a flexible chain; For linking group; n is 25.

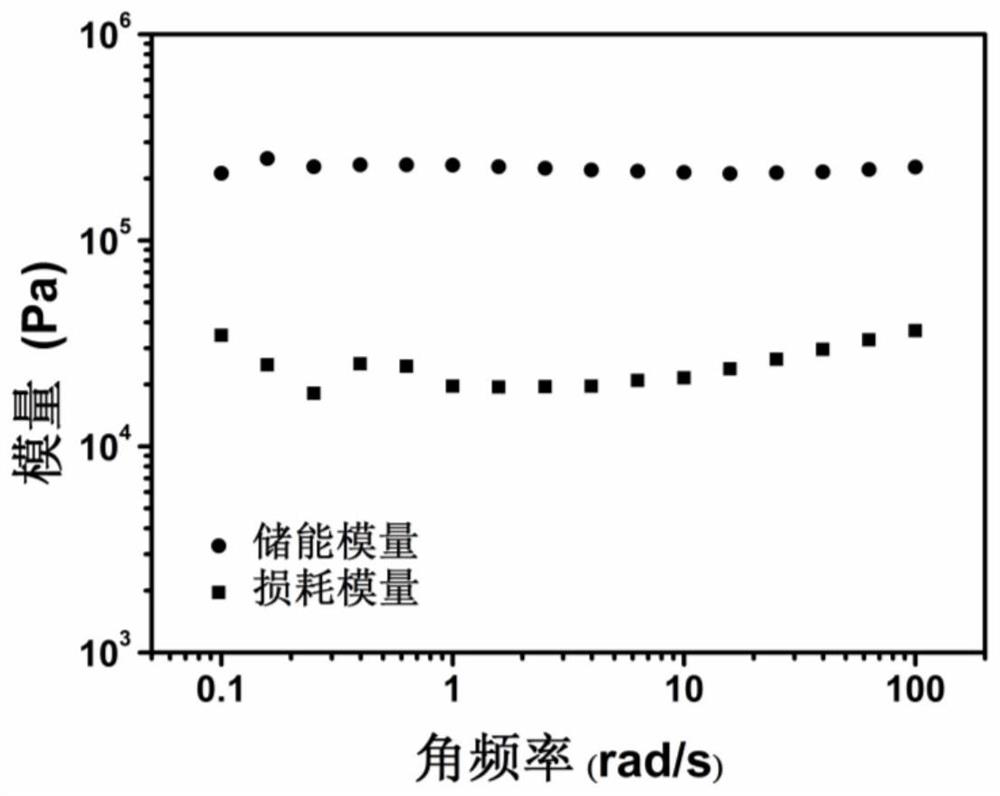

[0055] The above photoresponsive gel has fast and reversible dual response characteristics to light and heat. The photoresponsive gel becomes a clear solution after being heated at 90°C for 5 minutes, and the solution is cooled to room temperature to form a gel again; the photoresponsive gel is used for Green light irradiation for 10 minutes turned into a clear solution, and the solution re-formed a gel after blue light irradiation for 10 minutes. The saturation storage modulus of the photoresponsive gel measured by rotational rheometer is 2.1×10 5 Pa, the photoisomerization rate of azobenzene is 0.030s -1 . This photoresponsive gel can b...

Embodiment 2

[0063] A photoresponsive gel provided in this embodiment includes 7wt% photoresponsive polymer gelling factor and 93wt% tetrahydrofuran, wherein the structure of the photoresponsive polymer gelling factor is:

[0064]

[0065] In the structure of photoresponsive polymer gelling factor is a flexible chain; For linking group; n is 40.

[0066] The photoresponsive gel has fast and reversible dual response characteristics to light and heat; the photoresponsive gel turns into a clear solution after being heated at 90°C for 5 minutes, and the solution is cooled to room temperature to form a gel again. The photoresponsive gel turned into a clear solution after being irradiated with ultraviolet light for 10 minutes, and the solution re-formed into a gel after 10 minutes of being irradiated with visible light.

[0067] The preparation method of this photoresponsive gel is as follows:

[0068] (1) Under ice-bath conditions, add 10 grams (90 mmol) of p-aminophenol to 100 millilit...

Embodiment 3

[0074]A photoresponsive gel provided in this embodiment includes 6.5wt% photoresponsive polymer gelling factor and 93.5wt% dioxane, wherein the structure of the photoresponsive polymer gelling factor is:

[0075]

[0076] In the structure of photoresponsive polymer gelling factor is a flexible chain; For linking group; n is 26.

[0077] The photoresponsive gel has fast and reversible dual response characteristics to light and heat: the photoresponsive gel turns into a clear solution after being heated at 90°C for 5 minutes, and the solution is cooled to room temperature to form a gel again;

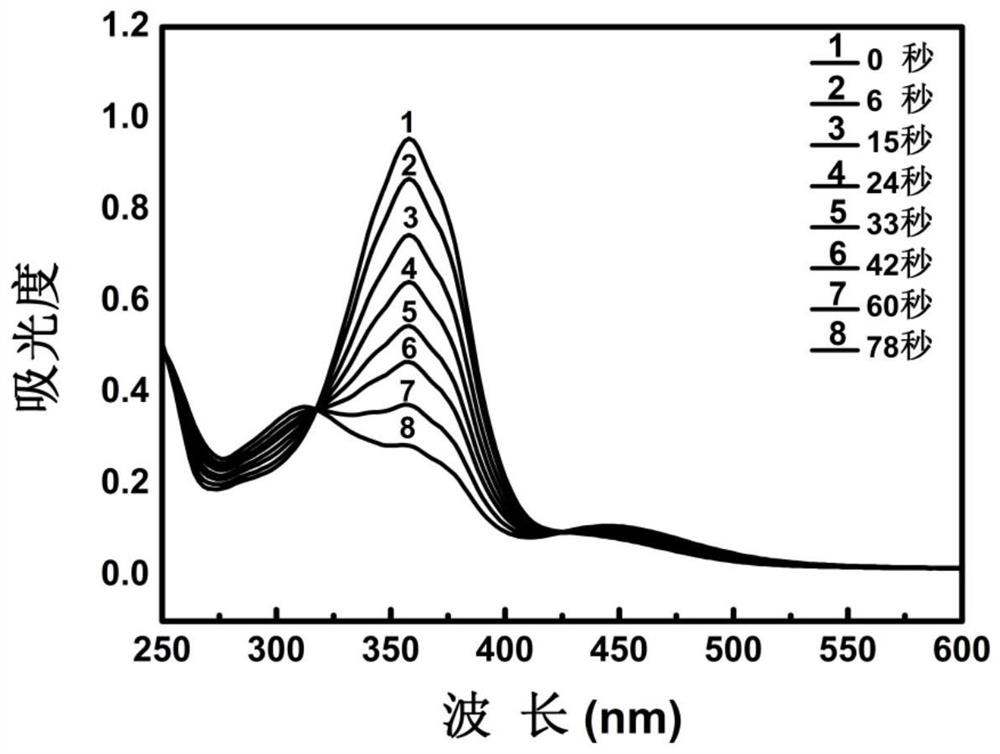

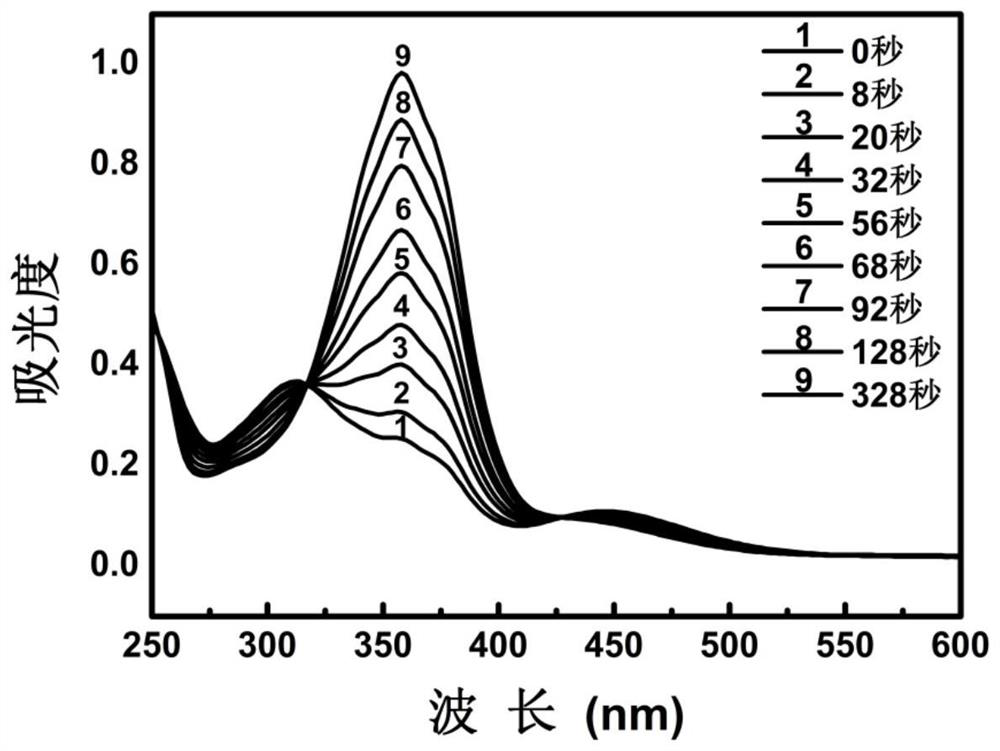

[0078] figure 1 The photoresponsive polymer gelling factor solution prepared for this embodiment is irradiated with ultraviolet light for different time UV-visible absorption spectra; from figure 1 It can be seen that the absorbance of the solution gradually decreases with the increase of the ultraviolet light irradiation time; the photoresponsive gel becomes a clear solution afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com