Method for regenerating waste engine oil by combination of solvent extraction and extraction centrifugation

A technology of waste engine oil and centrifugal compounding, which is applied in the petroleum industry, treating hydrocarbon oil, lubricating composition, etc., can solve the problems of large amount of sulfuric acid and white clay, low oil yield, high operating cost, etc., and achieves low price, The effect of low solvent toxicity and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

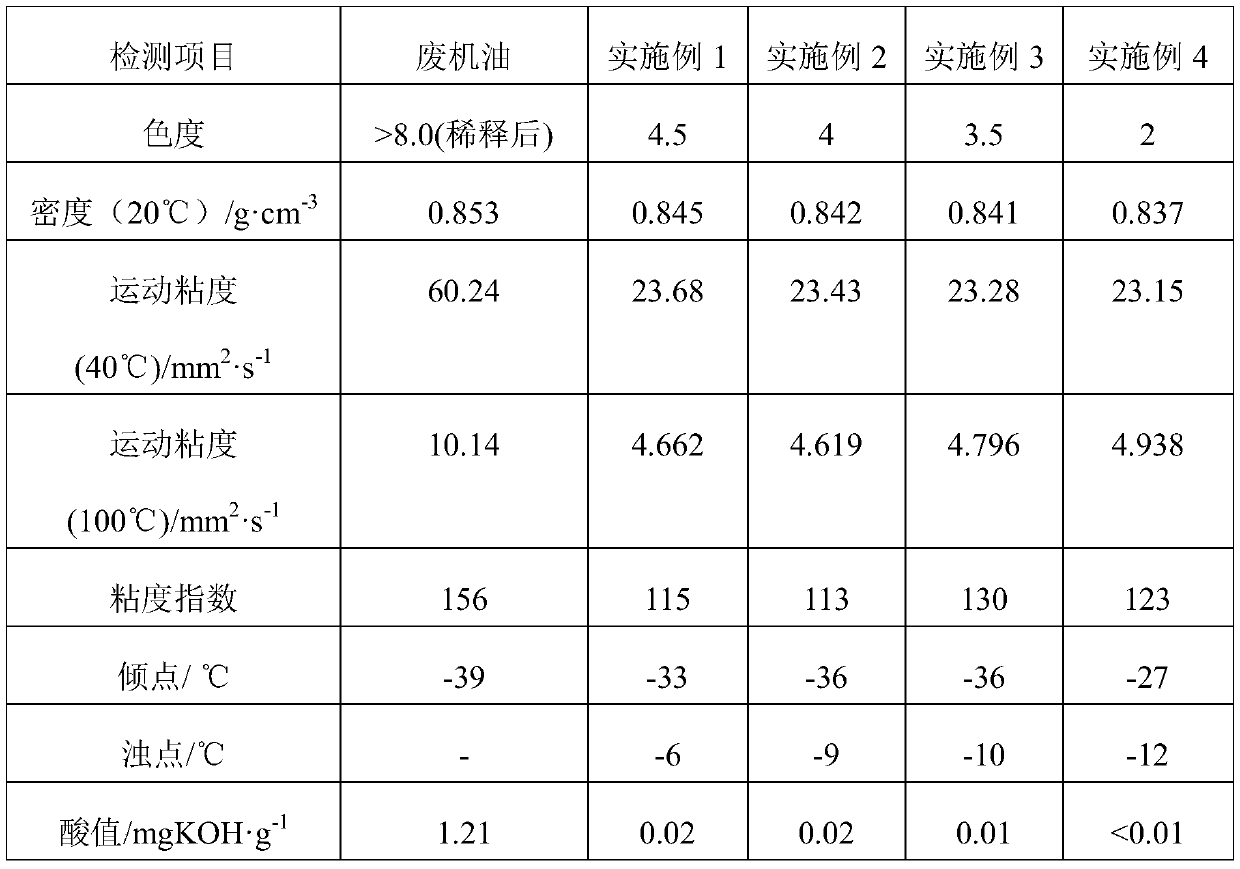

Examples

Embodiment 1

[0031] Put 100g of waste engine oil in a 1000ml round bottom flask, add 300g of a mixed solution of methanol, n-butanol and toluene, wherein the mass ratio of the mixed solvent is methanol:n-butanol:toluene=1:2:1, then add 0.180 g of ethanolamine was placed on a constant temperature heating magnetic stirrer, the heating switch and the stirring switch were turned on, the temperature was raised to 50° C., and the heating and stirring were stopped after constant temperature extraction for 20 minutes. After extraction and flocculation, introduce the mixed solution into the separatory funnel, put it in a constant temperature box, and separate the sediment in the separatory funnel after standing at 50°C for 12 hours. , Under the condition of pressure -0.1Mpa, the organic solvent is removed by vacuum distillation and recovered to obtain the initially refined waste engine oil.

[0032] Stir and mix the initially refined waste engine oil with NMP at a volume ratio of 1:1, then place it...

Embodiment 2

[0035] Put 100g of waste engine oil in a 1000ml round bottom flask, add 400g of a mixed solution of methanol, n-butanol and toluene, wherein the mass ratio between the mixed solvents is methanol:n-butanol:toluene=1:3:1, and then add 0.480 g of ethanolamine was placed on a constant temperature heating magnetic stirrer, the heating switch and the stirring switch were turned on, the temperature was raised to 40° C., and the heating and stirring were stopped after constant temperature extraction for 30 minutes. After the extraction and flocculation is completed, the mixed solution is introduced into the separatory funnel, placed in a constant temperature box, and the sediment in the separatory funnel is separated after standing at 40°C for 12 hours, and the supernatant is poured into a 1L distillation bottle. Under the condition of pressure -0.1Mpa, the organic solvent is distilled off under reduced pressure and recovered to obtain the initially refined waste engine oil.

[0036] ...

Embodiment 3

[0039] Put 100g of waste engine oil in a 1000ml round bottom flask, add 500g of a mixed solution of methanol, n-butanol and toluene, wherein the mass ratio of the mixed solvent is methanol:n-butanol:toluene=1:4:1, and then add Put 0.900 g of ethanolamine on a constant temperature heating magnetic stirrer, turn on the heating switch and stirring switch, raise the temperature to 30°C, and stop heating and stirring after pumping at constant temperature for 40 minutes. After the extraction and flocculation is completed, the mixed solution is introduced into the separatory funnel, placed in a constant temperature box, and the sediment in the separatory funnel is separated after standing at 30°C for 12 hours, and the supernatant is poured into a 1L distillation bottle. Under the condition of pressure -0.1Mpa, the organic solvent is distilled off under reduced pressure and recovered to obtain the initially refined waste engine oil.

[0040] Stir and mix the initially refined waste en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com