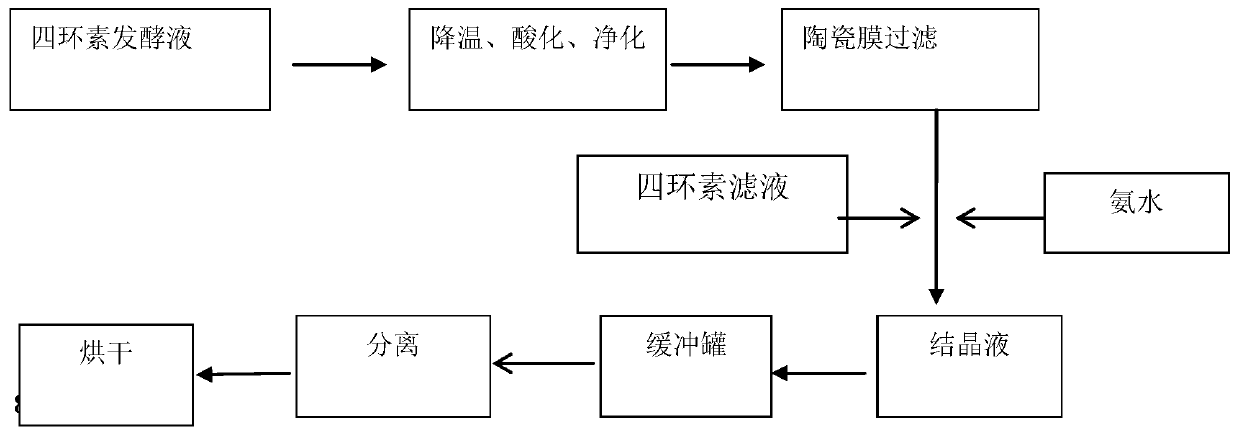

Continuous crystallization method of tetracycline

A tetracycline base and tetracycline technology, applied in organic chemistry, carboxylic acid amide separation/purification, etc., can solve the problems of material handling, storage, drying workload, operator physical damage, and labor intensity, etc., to achieve The effect of shortening the solution supersaturation time, high degree of filtration automation and improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dilute tetracycline fermentation broth (potency 27825μ / ml) with water to titer 8000μ / ml, cool down to 10°C, acidify with oxalic acid, adjust pH value to 1.7, add purifiers (yellow blood salt, zinc sulfate, borax) after purification Ceramic ultra-membrane filtration, in the later stage of filtration, use pH 1.7 oxalic acid water for top washing, and tetracycline filtrate and oxalic acid top washing water are mixed evenly and then sampled for testing.

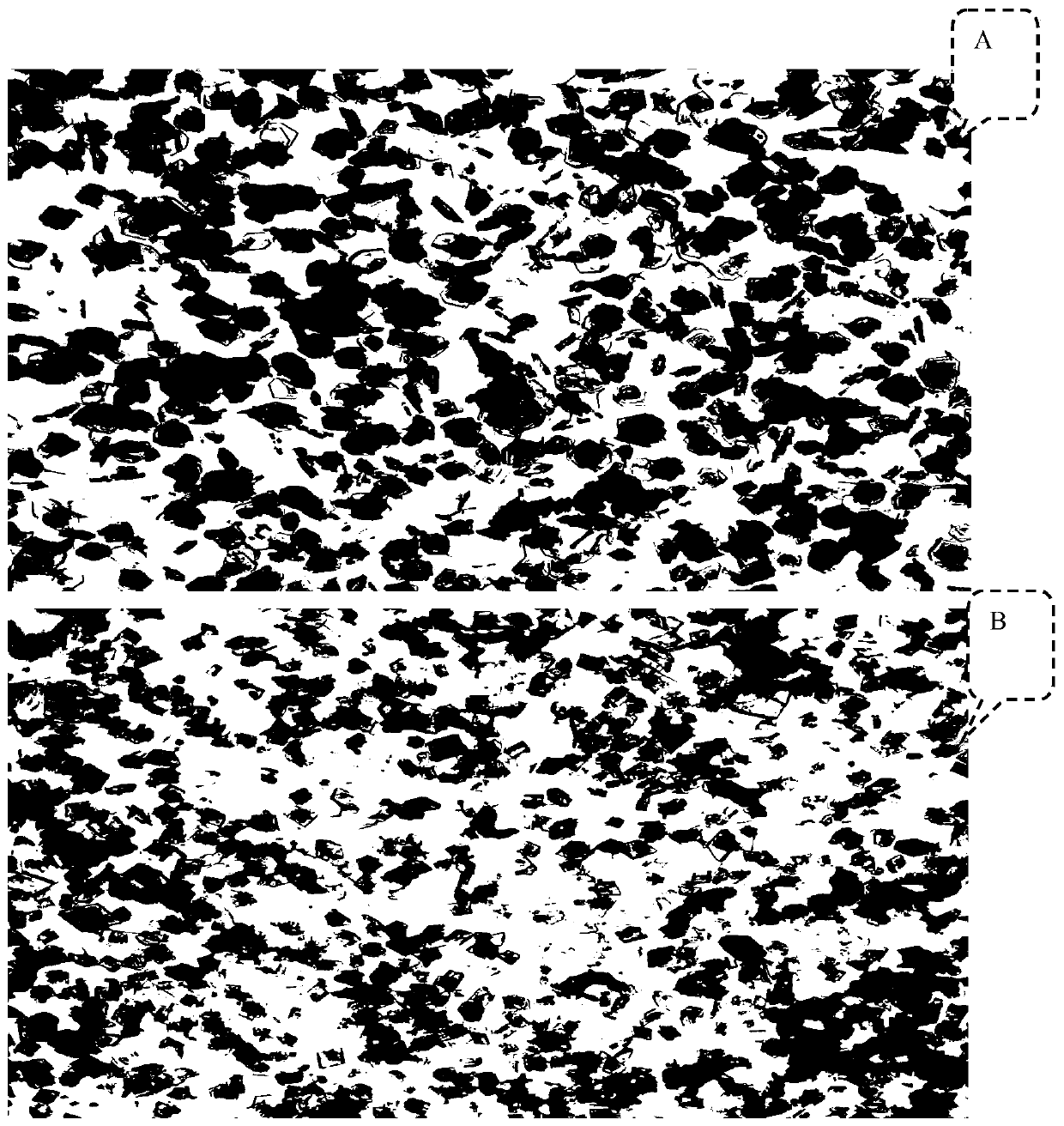

[0027] Take 4L of the above-mentioned tetracycline filtrate and oxalic acid top wash water mixture, with a potency of 6575μ / ml, mix the tetracycline filtrate and ammonia water in the delivery pipeline through a peristaltic pump (control the flow rate ratio of filtrate and ammonia water at 50:1), and then continue to flow to In the 2L reaction flask, the crystallization temperature was controlled at 5°C, and the pH value was at 4.5. After feeding for 20 minutes and the volume of the mixed solution reaches 70-80% of the volu...

Embodiment 2

[0029] Dilute tetracycline fermentation broth (potency 28017μ / ml) with water to titer 8000μ / ml, cool to 10°C, acidify with oxalic acid, adjust pH value to 1.6, add purifiers (yellow blood salt, zinc sulfate, borax) after purification Ceramic ultra-membrane filtration, in the later stage of filtration, oxalic acid water with pH 1.8 is used to circulate the top wash, and the tetracycline filtrate and oxalic acid top wash water are evenly mixed and then sampled for testing.

[0030] Take 4L of the above-mentioned tetracycline filtrate and oxalic acid top washing water mixture, with a potency of 6240μ / ml, mix the tetracycline filtrate and ammonia water in the delivery pipeline through a peristaltic pump (control the flow rate ratio of filtrate and ammonia water to 30:1), and then continue to flow to In a 2L reaction flask, control the crystallization temperature at 5°C and the pH value at 5.0. When the feeding time is 40min, when the volume of the mixed solution reaches 70-80% of ...

Embodiment 3

[0032] Dilute tetracycline fermentation broth (potency 31076μ / ml) with water to titer 9000μ / ml, cool down to 10°C, acidify with oxalic acid, adjust pH value to 1.8, add purifiers (yellow blood salt, zinc sulfate, borax) after purification Ceramic ultra-membrane filtration, in the later stage of filtration, oxalic acid water with pH 1.9 is used for top washing, and the tetracycline filtrate and oxalic acid top washing water are mixed evenly and then sampled for testing.

[0033] Take 4L of the above-mentioned tetracycline filtrate and oxalic acid top washing water mixture, the potency is 8285μ / ml, mix the tetracycline filtrate and ammonia water in the delivery pipeline through a peristaltic pump (control the flow rate ratio of filtrate and ammonia water to 40:1), and then continue to flow to In the 2L reaction flask, the crystallization temperature was controlled at 7°C, and the pH value was 4.6. When the feeding time is 30 minutes and the volume of the mixed solution reaches 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com