A kind of nano cutting oil and its preparation method and application

A nano-cutting and nano-silica technology, which is applied in the petroleum industry and lubricating compositions, etc., can solve problems such as easy cracking and failure of the lubricating oil film, cutting oil that cannot meet the corresponding precision requirements, and affecting the service life of the tool and the machining accuracy of the workpiece. Achieve good chemical protection, good working environment, and meet the requirements of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

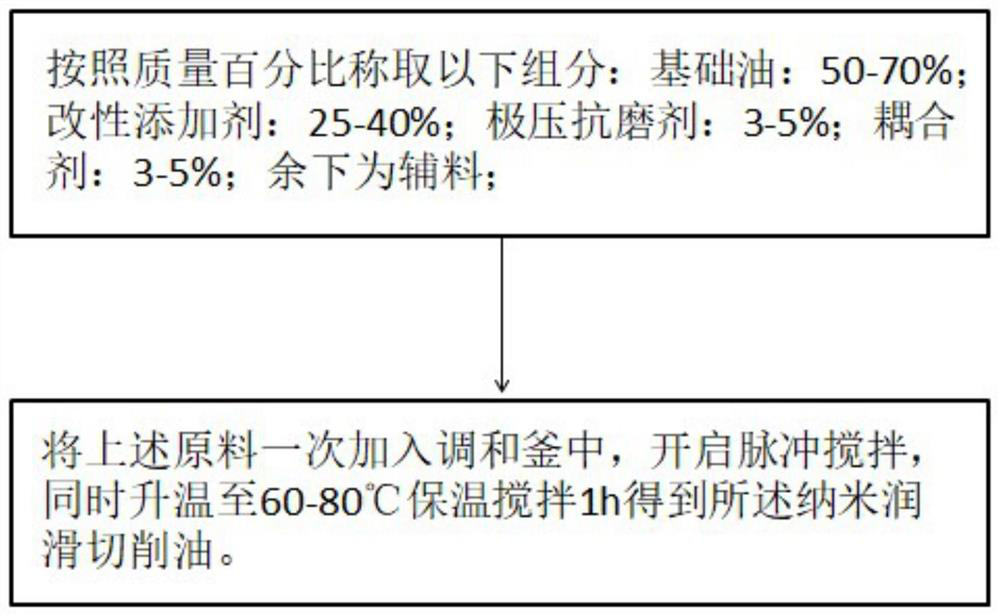

Method used

Image

Examples

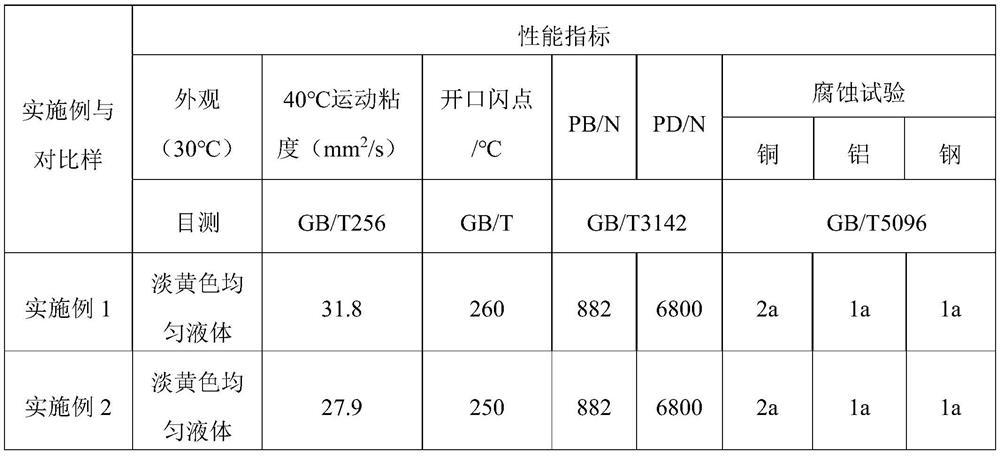

Embodiment 1

[0050] Turn on the stainless steel blending kettle for pulse stirring, raise the temperature to 60-70°C, add 50% base oil 150SN, 60SN (the mass ratio of 150SN to 60SN is 1:2), and then add 10% nano-silica Additives, 22% oxidized rapeseed oil and isooctyl oleate (mass ratio of oxidized rapeseed oil to isooctyl oleate is 3:1), 5% diethylene glycol monobutyl ether, 1% methylbenzotri Azole, 5% dodecenylsuccinic acid, 2% 4,4-dioctyl diphenylamine, 3% non-reactive vulcanized extreme pressure antiwear agent, 2% polyisobutylene with a molecular weight of 15000, to be After adding all the additives, keep stirring at 70°C for 1 hour. After all the additives are dissolved evenly and the main performance indicators pass the test, they are taken out of the kettle for packaging.

Embodiment 2

[0052]Turn on the pulse stirring of the stainless steel blending kettle, heat up to the temperature range of 60-70°C, add 65% base oil 60N, add 5% nano silicon dioxide additive, 15% vegetable oil and trimethylolpropane oleic acid diester ( The mass ratio of vegetable oil to trimethylolpropane oleic acid diester is 2:1), 3% of diethylene glycol monobutyl ether, 0.5% of methyl benzotriazole, 3% of dodecenyl butyl Diacid, 4.5% 4,4-dioctyldiphenylamine, 2% inactive vulcanized extreme pressure antiwear agent, 2% polyacrylate with a molecular weight of 20,000, after all the additives are added, keep stirring at 70°C for 1h , After all the additives are dissolved evenly, and the main performance indicators are tested to be qualified, they are packed out of the kettle.

Embodiment 3

[0054] Turn on the stainless steel blending kettle for pulse stirring, raise the temperature to 60-70°C, add 69% base oil 150N, add 5% nano-silica additive, 15% isooctyl oleate, 3% diethylene glycol Alcohol monobutyl ether, 1% methyl benzotriazole, 3% dinonyl naphthalene sulfonate, 1% 4,4-dioctyl diphenylamine and 2,5-di-tert-butyl-p-phenyl Diphenol (mass ratio 1:3), 1% molybdenum dialkyldithiocarbamate, 2% methacrylate and styrene copolymer with a molecular weight of 10,000 After all the additives are added, keep stirring at 70°C for 1h , After all the additives are dissolved evenly, and the main performance indicators are tested to be qualified, they are packed out of the kettle.

PUM

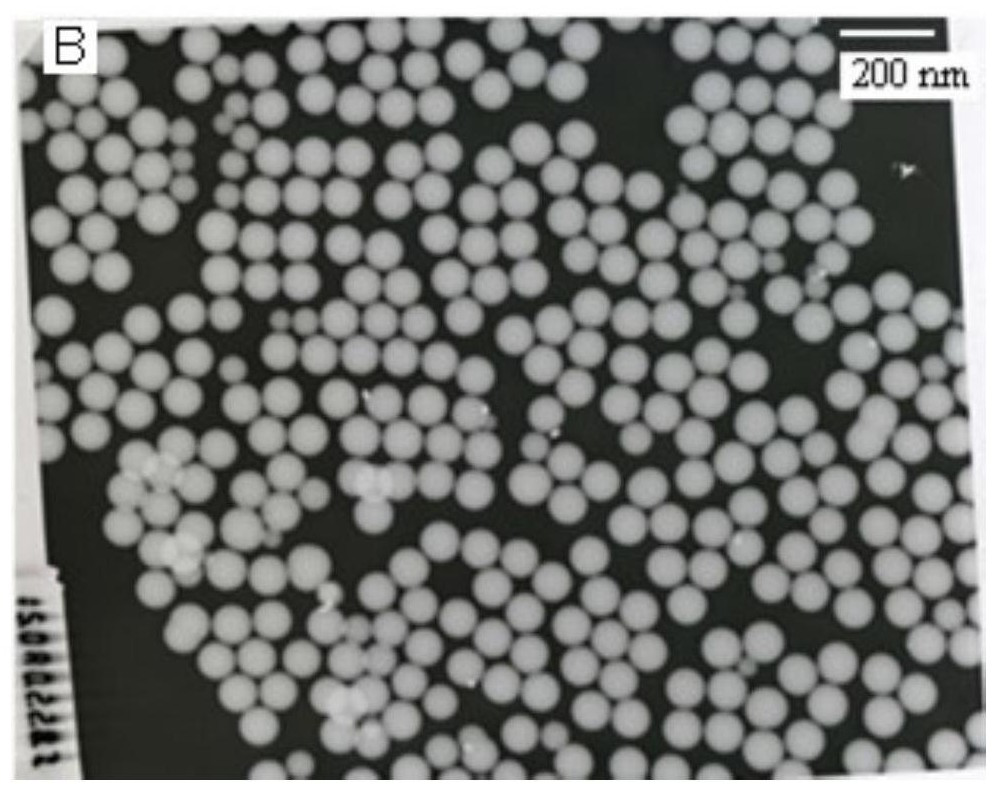

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com