Composite photocatalyst as well as preparation method and application thereof

A catalyst and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor catalyst stability, inability to reuse, poor catalyst activity, etc., and achieve strong oxidation resistance. , Solve the effect of easy loss and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiments of the present invention provide a method for preparing a composite photocatalyst, comprising the following steps:

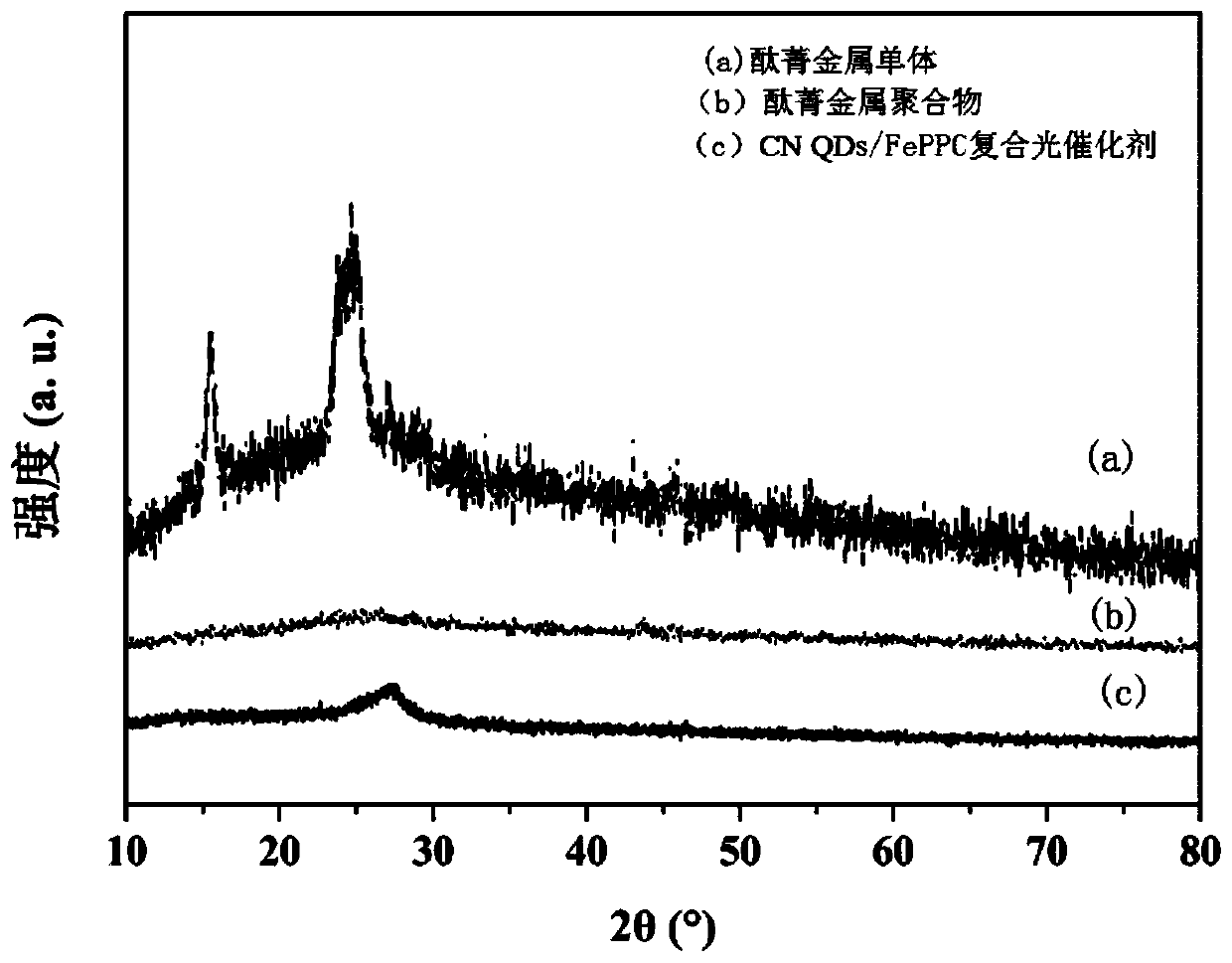

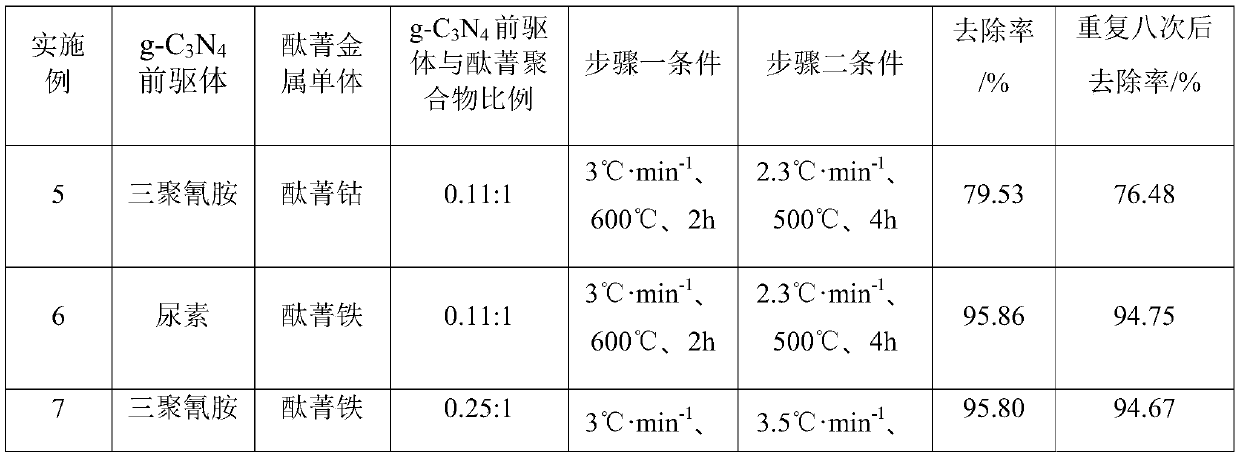

[0037] Step 1. Weigh 1.0 g of iron phthalocyanine monomer (FePc) and grind it fully in an agate mortar, put it into a tube furnace, and under the protection of nitrogen atmosphere, raise the temperature to 600 °C at a heating rate of 3 °C / min, and Roasting at this temperature for 2 hours at a constant temperature to obtain metal phthalocyanine polymer (FePPc); wherein, the flow rate of nitrogen gas is 100cm 3 / min;

[0038] Step 2. Weigh melamine and the iron phthalocyanine polymer according to the mass ratio of 0.11:1, put them into an agate mortar and grind them thoroughly, and put the mixture of the two into a high-temperature-resistant quartz boat, and place it horizontally In a tube furnace, the temperature was raised to 500° C. at a rate of 2.3° C. / min, and roasted at a constant temperature at this temperature for 4 hours. After the roa...

Embodiment 2

[0046] Embodiments of the present invention provide a method for preparing a composite photocatalyst, comprising the following steps:

[0047] Step 1. Weigh 1.0g of iron phthalocyanine monomer and grind it fully in an agate mortar, put it into a tube furnace, and under the protection of nitrogen atmosphere, raise the temperature to 550°C at a heating rate of 2°C / min, and keep at this temperature Roasting at constant temperature for 3 hours to obtain metal phthalocyanine polymer; wherein, the flow rate of nitrogen gas is 50cm 3 / min;

[0048] Step 2. Weigh melamine and the iron phthalocyanine polymer according to the mass ratio of 0.05:1, put them into an agate mortar and grind them thoroughly, and put the mixture of the two into a high-temperature-resistant quartz boat, and place it horizontally In a tube furnace, the temperature was raised to 600° C. at a rate of 5° C. / min, and roasted at a constant temperature for 3 hours at this temperature. After the roasting was complete...

Embodiment 3

[0051] Embodiments of the present invention provide a method for preparing a composite photocatalyst, comprising the following steps:

[0052] Step 1. Weigh 1.0g of iron phthalocyanine monomer, grind it fully in an agate mortar, put it into a tube furnace, and under the protection of nitrogen atmosphere, raise the temperature to 700°C at a heating rate of 5°C / min, and keep at this temperature Roasting at a constant temperature for 0.5h to obtain a metal phthalocyanine polymer; wherein, the flow rate of nitrogen gas is 200cm 3 / min;

[0053] Step 2. Weigh melamine and the iron phthalocyanine polymer according to the mass ratio of 0.43:1, put them into an agate mortar and grind them thoroughly, and put the mixture of the two into a high-temperature-resistant quartz boat, and place it horizontally In a tube furnace, the temperature was raised to 400° C. at a rate of 2° C. / min, and roasted at a constant temperature at this temperature for 6 hours. After the roasting was completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com