A kind of manufacturing method of light-colored outdoor recombined bamboo

A technology for recombining bamboo materials and manufacturing methods, applied in the direction of manufacturing tools, pretreatment and application of molding materials, etc., can solve the problems of poor bonding ability between bamboo fiber bundles and adhesives, damage to the internal structure of bamboo fibers, and damage to the strength of bamboo fibers. Achieve the effect of reducing pigmentation, reducing the degree of damage, and quickly softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

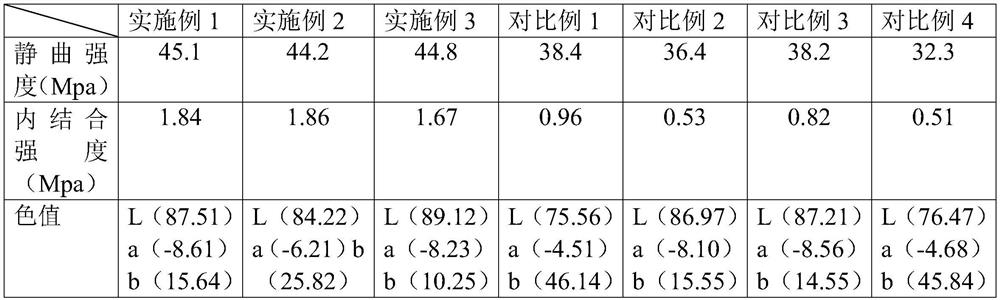

Examples

Embodiment 1

[0038] A kind of manufacture method of reconstituted bamboo for light-color outdoors, comprises the following steps,

[0039] (1) Unit preparation: with 100 parts by mass of bamboo slices as raw material, the bamboo slices are placed in 0.4mol / L glacial acetic acid and soaked in 0.4mol / L glacial acetic acid, soaked at 75°C for 5min to carry out primary acylation treatment, remove the glacial acetic acid solution, When the temperature drops to 50°C, add 5mol / L maleic anhydride and dicyclohexylcarbodiimide mixture, soak for 15min, and carry out secondary acylation treatment.

[0040] Put the above secondary acylation-treated bamboo slices into 0.7% second-step softening solution, add 0.5% vitamin C at the same time, and carry out enzymatic hydrolysis for 20 minutes.

[0041] Add vegetable oil to alkaline water for emulsification, put the bamboo slices after enzymatic treatment into the emulsified vegetable oil for 20 minutes,

[0042] After the softening treatment, the softened...

Embodiment 2

[0056] A kind of manufacture method of reconstituted bamboo for light-color outdoors, comprises the following steps,

[0057] (1) Unit preparation: with 100 parts by mass of bamboo slices as raw material, the bamboo slices are placed in 0.4mol / L glacial acetic acid and soaked in 0.4mol / L glacial acetic acid, soaked at 75°C for 15min to carry out primary acylation treatment, remove the glacial acetic acid solution, When the temperature drops to 50°C, add 5mol / L maleic anhydride and dicyclohexylcarbodiimide mixture, soak for 20min, and carry out secondary acylation treatment.

[0058] Put the above secondary acylation-treated bamboo slices into 0.7% second-step softening solution, add 0.5% vitamin C at the same time, and carry out enzymatic hydrolysis for 20 minutes.

[0059] Add vegetable oil to alkaline water for emulsification, put the bamboo slices after enzymatic treatment into the emulsified vegetable oil for 20 minutes,

[0060] After the softening treatment, the softene...

Embodiment 3

[0073] A kind of manufacture method of reconstituted bamboo for light-color outdoors, comprises the following steps,

[0074] (1) Unit preparation: with 100 parts by mass of bamboo slices as raw material, the bamboo slices are placed in 0.4mol / L glacial acetic acid and soaked in 0.4mol / L glacial acetic acid, soaked at 75°C for 5min to carry out primary acylation treatment, remove the glacial acetic acid solution, When the temperature drops to 50°C, add 5mol / L maleic anhydride and dicyclohexylcarbodiimide mixture, soak for 15min, and carry out secondary acylation treatment.

[0075] Put the above secondary acylation-treated bamboo slices into 0.7% second-step softening solution, add 0.5% vitamin C at the same time, and carry out enzymatic hydrolysis for 20 minutes.

[0076] Add vegetable oil to alkaline water for emulsification, put the bamboo slices after enzymatic treatment into the emulsified vegetable oil for 20 minutes,

[0077] After the softening treatment, the softened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com