Wastewater zero-discharge process for making acid through purifying activated charcoal fume and system

A technology of flue gas purification and activated carbon, which is applied in the fields of gaseous effluent wastewater treatment, chemical instruments and methods, degassed water/sewage treatment, etc. Complex water quality and other issues to achieve the effects of reducing emissions, improving processing capacity, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

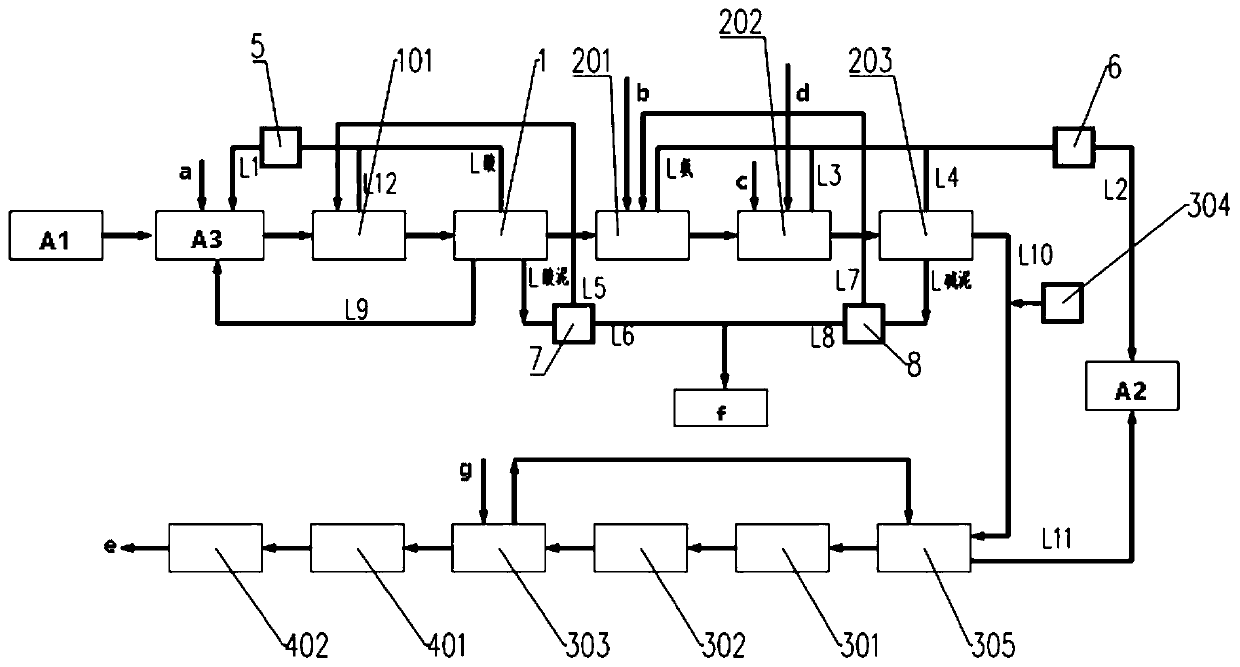

[0157] According to the first embodiment of the present invention, there is provided a zero-discharge process of activated carbon flue gas purification of acid-making wastewater:

[0158] A zero-discharge process for acid-making wastewater purified by activated carbon flue gas, comprising the following steps:

[0159] 1) Precipitate the complex acid sewage in the acid precipitation device 1, and the gas generated during the precipitation process passes through the acid gas return air duct L 酸 Enter the acid gas recovery unit 5 for recovery.

[0160] 2) The acid-making complex sewage after being precipitated by the acid precipitation device 1 is sequentially passed into the first neutralization tank 201, the first oxidation tank 202 and the flocculation sedimentation tank 203 of the metal ion precipitation device 2 for metal ion precipitation, and the first neutralization The ammonia gas produced in the tank 201 , the first oxidation tank 202 and the flocculation-sedimentation...

Embodiment 1

[0205] A zero-discharge process for acid-making wastewater purified by activated carbon flue gas, comprising the following steps:

[0206] 1) Precipitate the complex acid sewage in the acid precipitation device 1, and the gas generated during the precipitation process passes through the acid gas return air duct L 酸 Enter acid gas recovery unit 5 to reclaim;

[0207] 2) The acid-making complex sewage after being precipitated by the acid precipitation device 1 is sequentially passed into the first neutralization tank 201, the first oxidation tank 202 and the flocculation sedimentation tank 203 of the metal ion precipitation device 2 for metal ion precipitation, and the first neutralization The ammonia produced in the pond 201, the first oxidation pond 202 and the flocculation sedimentation pond 203 enters the ammonia gas recovery device 6 to reclaim;

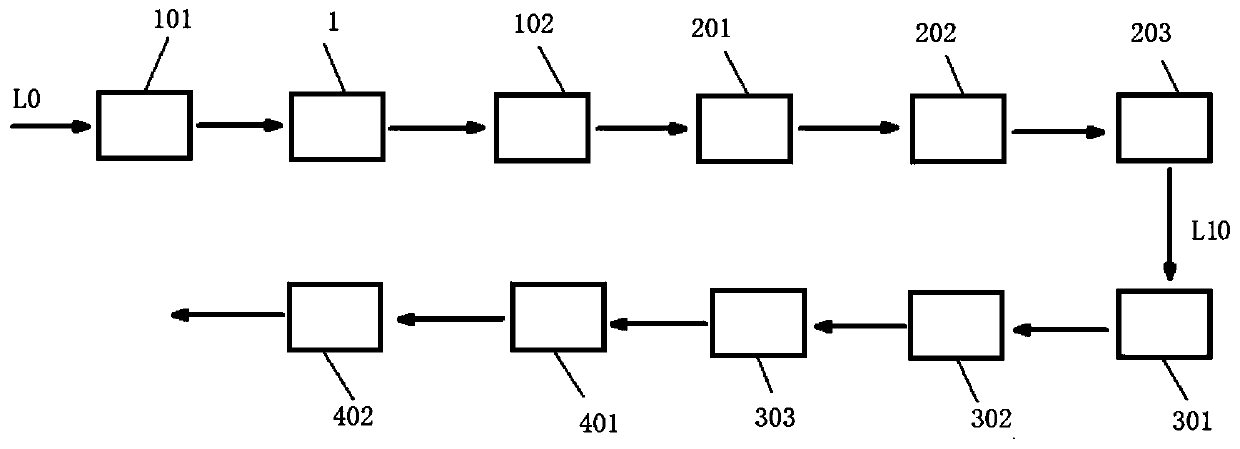

[0208] 3) Pass the complex acid-making sewage settled in the flocculation-sedimentation tank 203 through the tenth pipeline L10...

Embodiment 2

[0212] Repeat embodiment 1, just step 2) in, the alkaline bottom sludge that flocculation sedimentation tank 203 produces is passed into bottom sludge de-alkaline dehydration device 8, and the alkaline filtrate that produces in bottom sludge de-alkaline dehydration device 8 passes through the first step. The seven pipelines L7 are recovered, and the dealkalized sludge produced in the bottom sludge dealkaline dehydration device 8 is recovered through the eighth pipeline L8; in step 3), lye is added to the tenth pipeline L10 through the lye replenishing device 304 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com