Method for improving fermentation unit of erythromycin

A technology of erythromycin and unit, which is applied in the field of biology and new medicine, can solve the problems of increasing raw material and energy consumption, high extraction cost, and long fermentation cycle, so as to promote the growth and reproduction of bacteria, improve the level of fermentation technology, and shorten the fermentation period. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

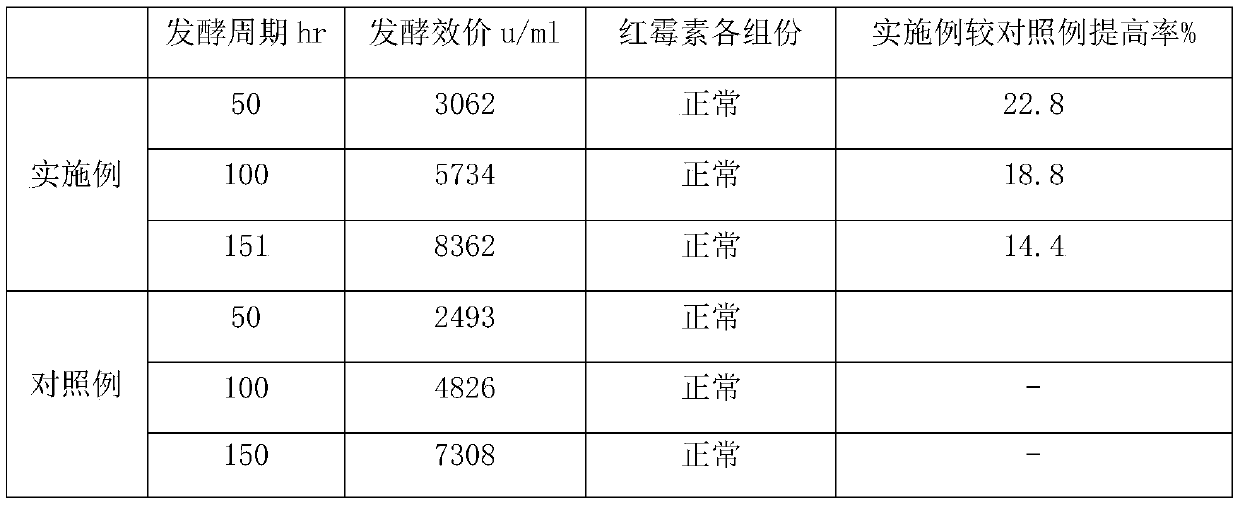

Embodiment 1

[0032] 1) Example fermentation medium composition: starch 580g / L, dextrin 150g / L, soybean powder 375g / L, corn steep liquor 125g / L, ammonium sulfate 40g / L, sodium chloride 37.5g / L, calcium carbonate 105g / L L, soybean oil 45g / L, nickel sulfate 0.03g / L.

[0033] 2) The medium composition of the control example: starch 580g / L, dextrin 150g / L, soybean flour 525g / L, corn steep liquor 300g / L, ammonium sulfate 40g / L, sodium chloride 37.5g / L, calcium carbonate 105g / L , soybean oil 50g / L.

[0034] 3) Prepare and cultivate seeds of all levels according to the above-mentioned requirements, including inclined spores, first-level seeds, and second-level seeds.

[0035] 4) Inoculate the secondary seed liquid cultivated in the above method into the sterilized fermentation medium of the embodiment and the fermentation medium of the control example under aseptic conditions, and cultivate according to the normal fermentation culture conditions. Hours, 100 hours, 150 hours to monitor the fermen...

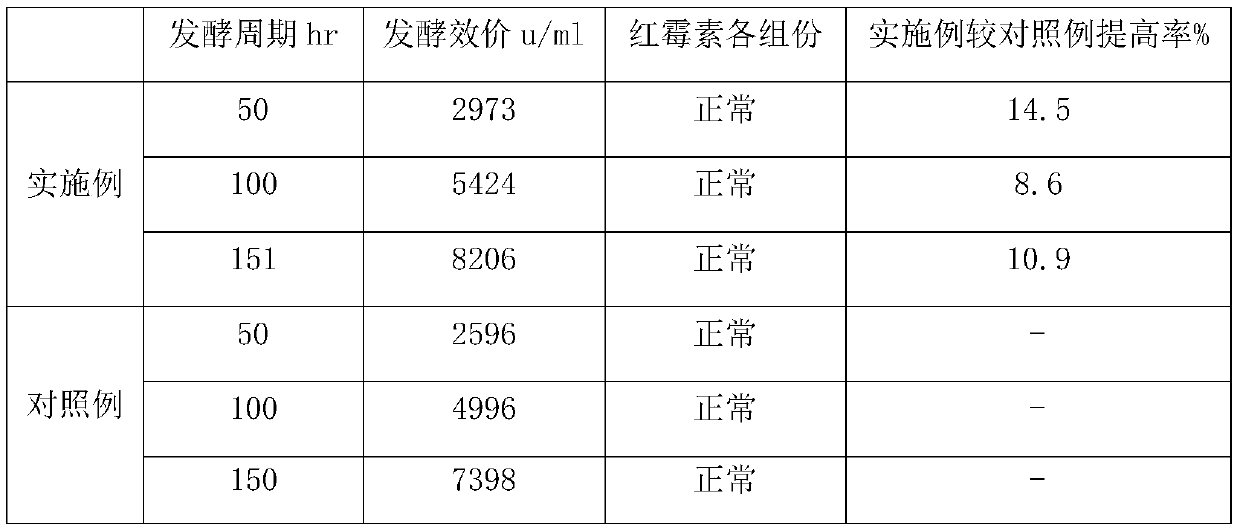

Embodiment 2

[0038] 1) Example fermentation medium composition: starch 580g / L, dextrin 150g / L, soybean powder 375g / L, corn steep liquor 125g / L, ammonium sulfate 40g / L, sodium chloride 37.5g / L, calcium carbonate 105g / L L, soybean oil 45g / L, nickel sulfate 0.05g / L.

[0039] 2) The medium composition of the control example: starch 580g / L, dextrin 150g / L, soybean flour 525g / L, corn steep liquor 300g / L, ammonium sulfate 40g / L, sodium chloride 37.5g / L, calcium carbonate 105g / L , soybean oil 50g / L.

[0040] 3) Prepare and cultivate seeds of all levels according to the above-mentioned requirements, including inclined spores, first-level seeds, and second-level seeds.

[0041] 4) Inoculate the secondary seed liquid cultivated in the above method into the sterilized fermentation medium of the embodiment and the fermentation medium of the control example under aseptic conditions, and cultivate according to the normal fermentation culture conditions, and ferment for 50 hours respectively , 100 hours...

Embodiment 3

[0044]1) Example fermentation medium composition: starch 580g / L, dextrin 150g / L, soybean powder 375g / L, corn steep liquor 125g / L, ammonium sulfate 40g / L, sodium chloride 37.5g / L, calcium carbonate 105g / L L, soybean oil 45g / L, nickel sulfate 0.06g / L.

[0045] 2) The medium composition of the control example: starch 580g / L, dextrin 150g / L, soybean flour 525g / L, corn steep liquor 300g / L, ammonium sulfate 40g / L, sodium chloride 37.5g / L, calcium carbonate 105g / L , soybean oil 50g / L.

[0046] 3) Prepare and cultivate seeds of all levels according to the above-mentioned requirements, including inclined spores, first-level seeds, and second-level seeds.

[0047] 4) Inoculate the secondary seed liquid cultivated in the above method into the sterilized fermentation medium of the embodiment and the fermentation medium of the control example under aseptic conditions, and cultivate according to the normal fermentation culture conditions, and ferment for 50 hours respectively , 100 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com