Calcium citrate/calcium sulfate composite bone cement loaded with vitamin D and its preparation method

A technology of calcium citrate and calcium sulfate, applied in the field of bone repair materials, can solve the problems of poor injectability, fast degradation, low strength, etc., and achieve the effects of good plasticity, improved cell activity, and good osteogenic ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 6

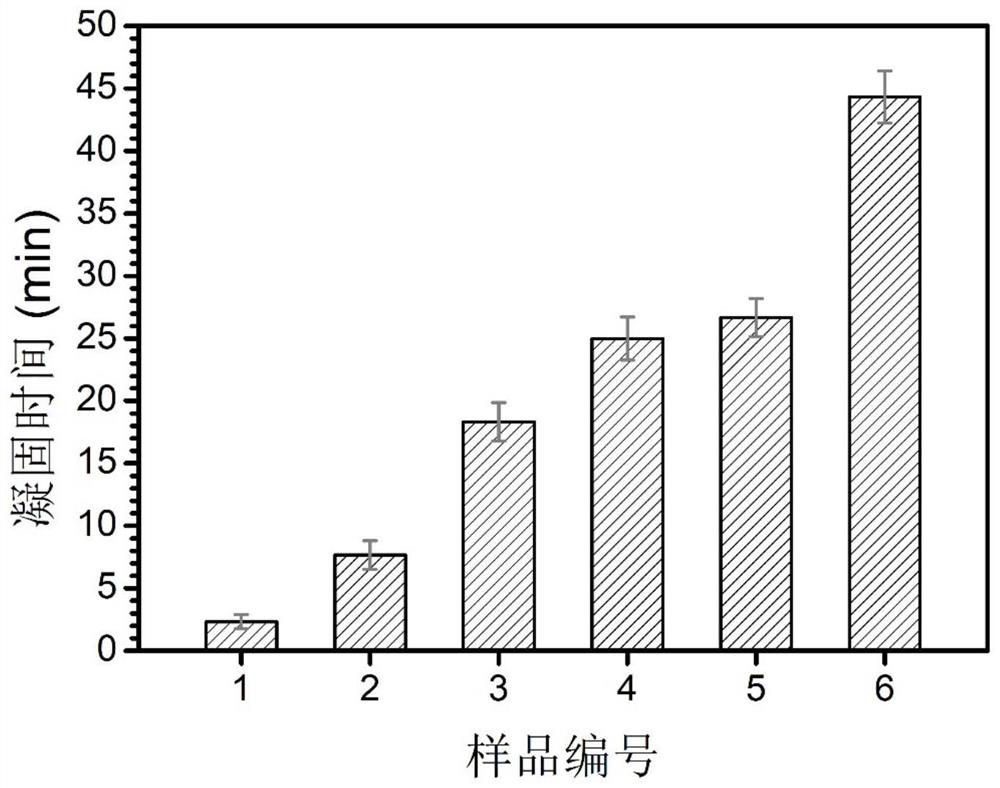

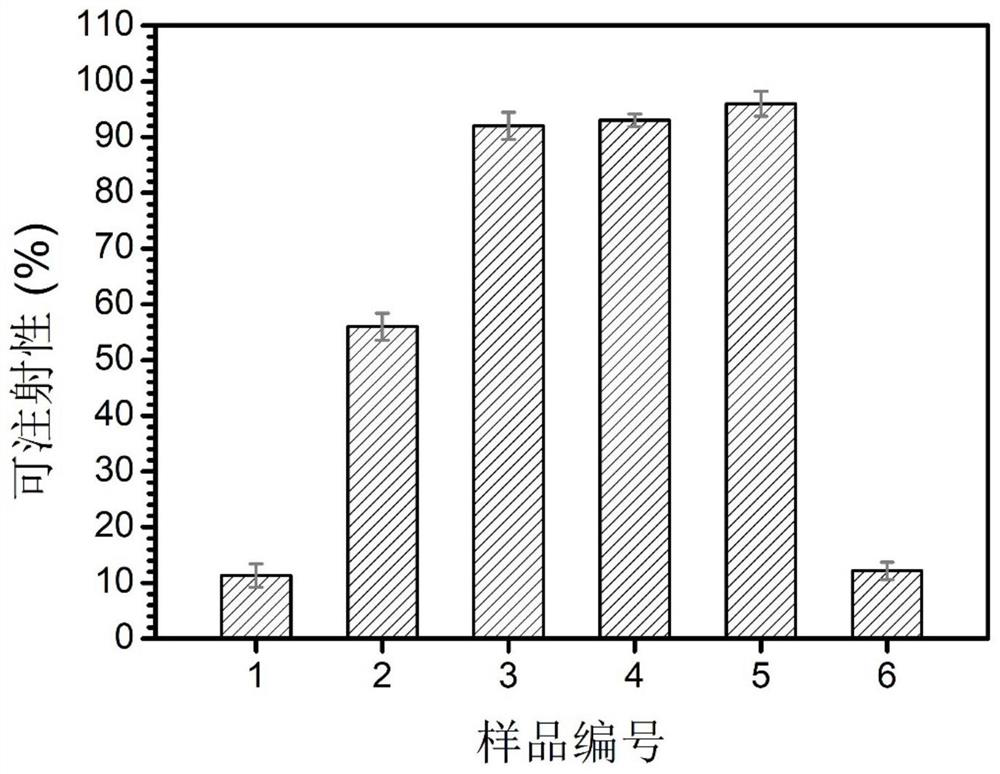

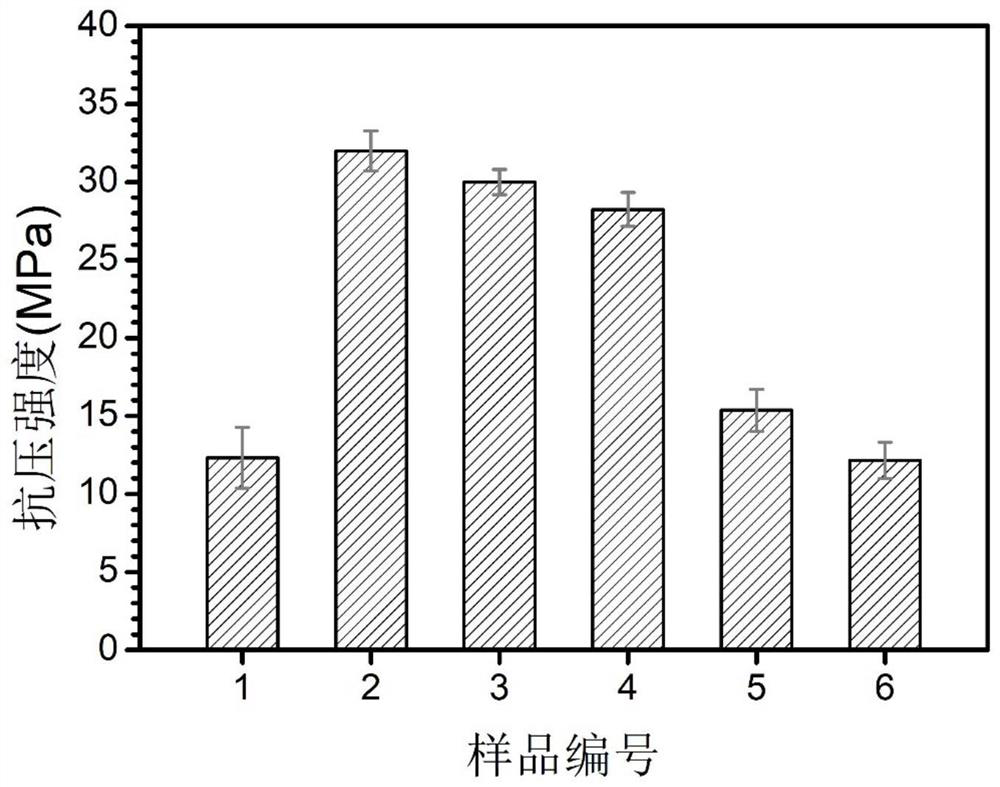

[0039] Prepare Example 1 according to the formula in Table 1, and its preparation method is: calcium citrate and calcium sulfate powder are weighed by the mass ratio in Table 1, then the composite powder after physical mixing is put into ball mill and ground 4h, The ball milling speed is 150 rpm, and then the solidified liquid is accurately measured according to the liquid-solid ratio in Table 1, wherein the solidified liquid is deionized water; the solidified liquid is added to the solid phase powder, stirred rapidly to form a bone cement slurry, and then The bone cement paste is put into a polytetrafluoroethylene mold with a diameter of 6 mm and a height of 7 mm and 12 mm for molding.

[0040] Formulation preparation example in table 1 embodiment 1-embodiment 6

[0041] Numbering Calcium Citrate / Calcium Sulfate Liquid-solid ratio (mL / g) Example 1 sample 1 0:1 0.19 Example 2 sample 2 1:4 0.21 Example 3 sample 3 2:3 0.23 Example ...

Embodiment 7- Embodiment 11

[0043] Preparation of vitamin D3-ethanol solution, weigh 1.25g of vitamin D3 powder and dissolve it in 100mL of absolute ethanol to prepare a vitamin D-ethanol solution with a concentration of 12.5mg / mL; then dilute the solution to obtain 2.5, 0.5 and 0.1mg / mL vitamin D3-ethanol solution.

[0044] Prepare Examples 7-11 according to the formula in Table 2. The preparation method is as follows: accurately weigh calcium citrate and calcium sulfate powders at a mass ratio of 3:2, and then put the physically mixed composite powder into a ball mill Grind for 4 hours, the ball milling speed is 150 rpm, and then accurately measure vitamin D3-ethanol solutions of different concentrations according to the liquid-solid ratio of 1.5mL / g (referring to the ratio of vitamin D3-ethanol solution to the composite powder), and add the solution to the compound powder Stir the powder with a magnetic stirrer for 15 minutes, then put it in a blast drying oven for 6 hours at 50°C, and finally grind th...

Embodiment 1-6

[0062] The sample solidified in the air for 3 days was ground into fine powder with a mortar, and the sample powder was analyzed by X-ray diffractometer to study the curing mechanism of the composite bone cement.

[0063] The XRD diffraction pattern when the sample is solidified for 3 days is as follows: Figure 4 , it can be seen that sample 1 is the main diffraction peak of calcium sulfate; sample 6 is the main diffraction peak of calcium citrate. Other samples were composite bone cements composed of calcium sulfate and calcium citrate. CaSO in sample 4 and sample 5 4 2H 2 The diffraction peak of O disappeared, probably because the chelation effect hindered the hydration process of calcium sulfate and inhibited the CaSO 4 2H 2 Generation of O.

[0064] 5, the situation of material degradation (the sample of embodiment 7-11):

[0065] The samples were tested for material degradation in phosphate buffered saline (PBS).

[0066] The preparation method of PBS is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com