Cathode material, preparation method of cathode material, and lithium ion battery

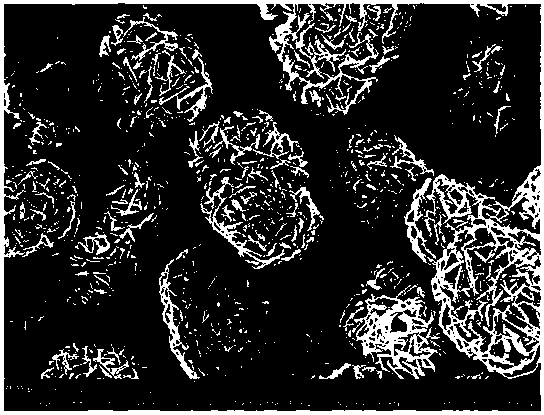

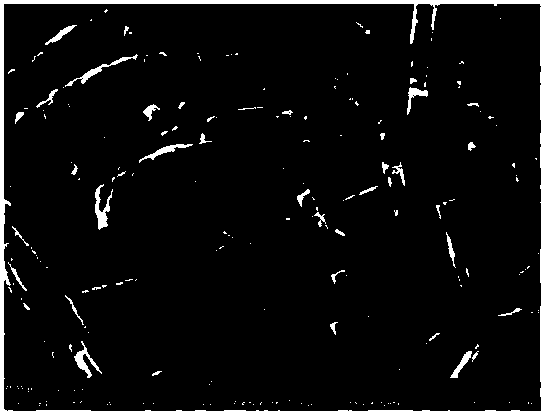

A positive electrode material and slurry technology, which is applied in the field of positive electrode materials and its preparation, can solve the problems of battery volume energy density decrease, gaps cannot be filled, unfavorable processing, etc., to improve the first charge and discharge performance, dense and regular arrangement, The effect of reducing space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Second object of the present invention provides a kind of preparation method of cathode material, described method comprises the following steps:

[0032] S1. After mixing the M source solution, the phosphorus source solution, the lithium source solution and the pH regulator, control the pH value of the reaction system to 8-10, perform emulsification and shearing to obtain slurry A, wherein the M source is a ferrous iron source Or ferrous iron source and manganese source;

[0033] S2. Suction filter the slurry A under the first inert atmosphere to obtain the slurry B, put the slurry B into the high-pressure reactor, and react to obtain the slurry C, the reaction temperature is 120-240°C, and the reaction time is 2-8h ;

[0034] S3. Continue to react in the autoclave after diluting the slurry C, the reaction temperature is 120-240°C, and the reaction time is 2-8h;

[0035] S4, filtering, washing and drying the product obtained in step S3 to obtain a positive electrode ...

Embodiment 1

[0063] Get 4mol ferrous chloride (purity is 99.9%), 4.04mol ammonium phosphate (purity is 99.5%) and 4000g deionized water, be made into the mixed solution of iron source and phosphorus source that iron concentration is 1mol / L, get 12.8mol Lithium chloride (purity is 99.5%), 3500g deionized water is made into the lithium source solution that lithium concentration is 3.66mol / L, gets 0.5mol sodium hydroxide (purity is 99.5%), 400g deionized water is made into concentration and is 1.25 mol / L pH regulator. Put the mixed solution of iron source and phosphorus source into the emulsified shear tank, turn on the shearer and stirring paddle, and keep the speed of the stirring paddle at 200r / min; add the lithium source solution and pH regulator at a uniform speed within 80min to shear In the reaction tank, after the lithium source solution is completely added to the reaction tank, the pH of the entire reaction system is finally controlled to 9.0 with the configured pH regulator to ensur...

Embodiment 2

[0065] Get 3.0mol ferrous sulfate (purity is 100%), 3.05mol ammonium hydrogen phosphate (purity is 99.2%) and 2500g deionized water, be made into the mixed solution of iron source and phosphorus source that iron concentration is 1.2mol / L, Get 9.05mol lithium nitrate (purity is 99.5%), 2511g deionized water are made into the lithium source solution that lithium concentration is 3.0mol / L, get 3.55mol potassium hydroxide, 2180g deionized water are made into concentration and be 1.63mol / L pH regulator. Put the mixed solution of iron source and phosphorus source into the emulsified shear tank, turn on the shearer and stirring paddle, and keep the speed of the stirring paddle at 400r / min; at the same time, add the lithium source solution and pH regulator at a uniform speed of about 40ml / min In the shearing reaction tank, after the lithium source solution is completely added in the reaction tank, the pH control of the entire reaction system is finally controlled to 8.5 with a configure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com