Method for producing diisobutylene by using mixed C4

A technology of diisobutene and isobutene, applied in the field of C4 polymerization, can solve the problems of difficult recovery of inhibitors, high trimer content, low diisobutene content, etc., and achieves the effects of simple recovery method, low energy consumption and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

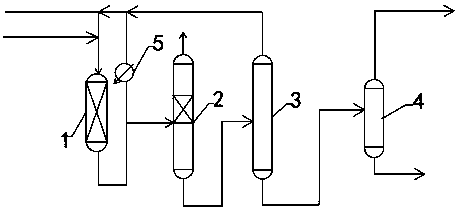

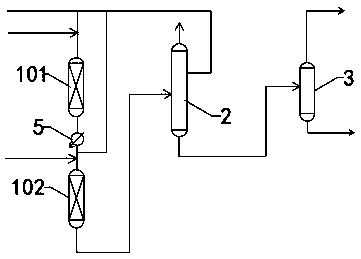

[0035] use as figure 1 Catalytic distillation process;

[0036] Mixed C4 contains 18.5% isobutene and 16.3% n-butene, feed rate: 300g / h;

[0037] Fixed-bed polymerization reactor catalyst loading: 500ml, the catalyst is a macroporous sulfonic acid cation exchange resin, and the exchange capacity is 4.5mmol [H+] / g; the preparation method of the polymerization catalyst comprises the following steps:

[0038] (1) Add 0.2g of hydroxypropylmethylcellulose, 0.3g of polyacrylamide, and 7g of sodium secondary alkyl sulfonate to 500g of water, heat and stir to dissolve completely and form a uniform aqueous solution. Then add the organic phase mixture composed of 90g styrene, 35g divinylbenzene, 0.9 gram benzoyl peroxide, 24g n-hexadecane, 6g tert-butyl neodecanoate, adjust the appropriate stirring speed, and heat up to 65°C, constant temperature reaction for 2 hours, then raise the temperature to 80°C, constant temperature reaction for 4 hours. The reaction product was filtered, the...

Embodiment 2

[0046] use as figure 1 Catalytic distillation process;

[0047] Mixed C4 contains 18.5% isobutene and 16.3% n-butene, feed rate: 300g / h;

[0048] Fixed-bed polymerization reactor catalyst loading: 300ml, catalyzer is macroporous sulfonic acid cation exchange resin, exchange capacity is 5.0 mmol [H+] / g, its preparation method is the same as the preparation method of polymerization catalyst among the embodiment 1, difference is: to Add 4g of hydroxypropylmethylcellulose, 0.3g of polyacrylamide, and 2g of sodium secondary alkylsulfonate to 450g of water, heat and stir to dissolve completely, forming a uniform aqueous solution. An organic phase mixture consisting of 60 g of styrene, 40 g of divinyltoluene, 3 g of benzoyl peroxide, 40 g of liquid paraffin, and 0.6 g of tert-butyl neodecanoate was added.

[0049] Catalytic distillation tower catalyst loading: 200ml;

[0050] Add polymerization inhibitor in the raw material, the mol ratio of inhibitor and isobutylene in the fresh ...

Embodiment 3

[0055] use as figure 1 Catalytic distillation process;

[0056] Mixed C4 contains 18.5% isobutene and 16.3% n-butene, feed rate: 300g / h;

[0057] Fixed-bed polymerization reactor catalyst load: 400ml, catalyzer is macroporous sulfonic acid cation exchange resin, and exchange capacity is 5.5mmol [H+] / g, and its preparation method is the same as the preparation method of polymerization catalyst among the embodiment 1, difference is: to Add 0.4g of hydroxypropyl methylcellulose, 6g of polyacrylamide, and 1g of sodium secondary alkylsulfonate to 500g of water, heat and stir to dissolve completely and form a uniform aqueous solution. Then add the organic phase mixture composed of 80g styrene, 30g divinyl toluene, 1.5 gram benzoyl peroxide, 33g n-dodecane, 4g tert-butyl peroxyneodecanoate;

[0058] Catalytic distillation tower catalyst loading: 200ml;

[0059] A polymerization inhibitor is added to the raw material, and the molar ratio of the inhibitor to isobutylene in the fresh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com