System and method for steel making by spraying limestone powder to bottom of converter

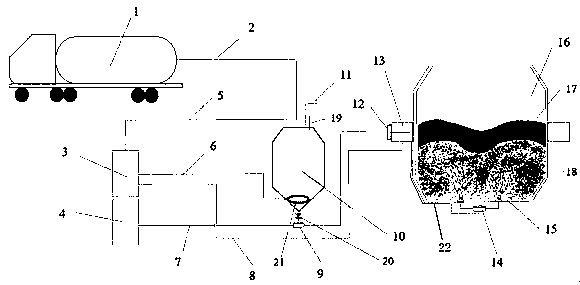

A limestone powder, converter smelting technology, applied in the direction of manufacturing converters, etc., can solve the problems of small contact area, limited injection range, and insufficient stirring effect of molten pool, etc., to increase the direct contact area and improve the stirring conditions. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

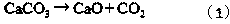

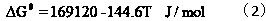

Method used

Image

Examples

Embodiment 1

[0046] 50 tons of converter bottom spray limestone powder steelmaking

[0047] The bottom of the converter is equipped with two double-layer casing type bottom blowing powder spray guns, which use oxygen, nitrogen and argon as carrier gases to spray limestone powder, and spray nitrogen and argon to the annular gap for cooling protection. Finally, the passivated limestone powder is sprayed into the converter through the double-layer casing type bottom blowing lance, the carrier gas is a mixed gas of oxygen and nitrogen, the proportion of oxygen injection is 75%, the proportion of nitrogen injection is 25%, and nitrogen is used as the Protective gas for ring seam, limestone powder injection speed is 150kg / min, the amount of lime added in the first batch is reduced by 800kg, light-burned dolomite and raw dolomite are added according to the requirement that the MgO content in the slag is greater than 8%, and the injection is until the carbon-oxygen reaction begins In the first 45s...

Embodiment 2

[0050] 120-ton converter bottom spraying limestone powder steelmaking

[0051] The bottom of the converter is equipped with two double-layer casing type bottom-blowing powder spray guns, which use oxygen, nitrogen and argon as carrier gases to spray limestone powder, and spray nitrogen and argon to the annular gap for cooling protection. After the converter is mixed with iron and steel scrap, the passivated limestone powder is sprayed into the converter through the bottom blowing lance, the carrier gas is a mixed gas of oxygen and nitrogen, the proportion of oxygen injection is 75%, the proportion of nitrogen injection is 25%, and nitrogen is used as the Ring seam protection gas, limestone powder injection speed is 180kg / min, the first batch of lime addition is reduced by 1200kg, light burnt dolomite and raw dolomite are added according to the requirement that the MgO content in the slag is greater than 8%, and the injection is until the carbon-oxygen reaction begins In the fi...

Embodiment 3

[0054] 300-ton converter bottom spraying limestone powder steelmaking

[0055] The bottom of the converter is equipped with two double-layer casing type bottom-blowing powder spray guns, which use oxygen, nitrogen and argon as carrier gases to spray limestone powder, and spray nitrogen and argon to the annular gap for cooling protection. After the converter is mixed with iron and steel scrap, the passivated limestone powder is sprayed into the converter through the bottom blowing lance, the carrier gas is a mixed gas of oxygen and nitrogen, the proportion of oxygen injection is 75%, the proportion of nitrogen injection is 25%, and nitrogen is used as the Ring seam protection gas, limestone powder injection speed is 200kg / min, the first batch of lime addition is reduced by 1400kg, light burnt dolomite and raw dolomite are added according to the requirement that the MgO content in the slag is greater than 8%, and the injection is until the carbon-oxygen reaction starts In the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com