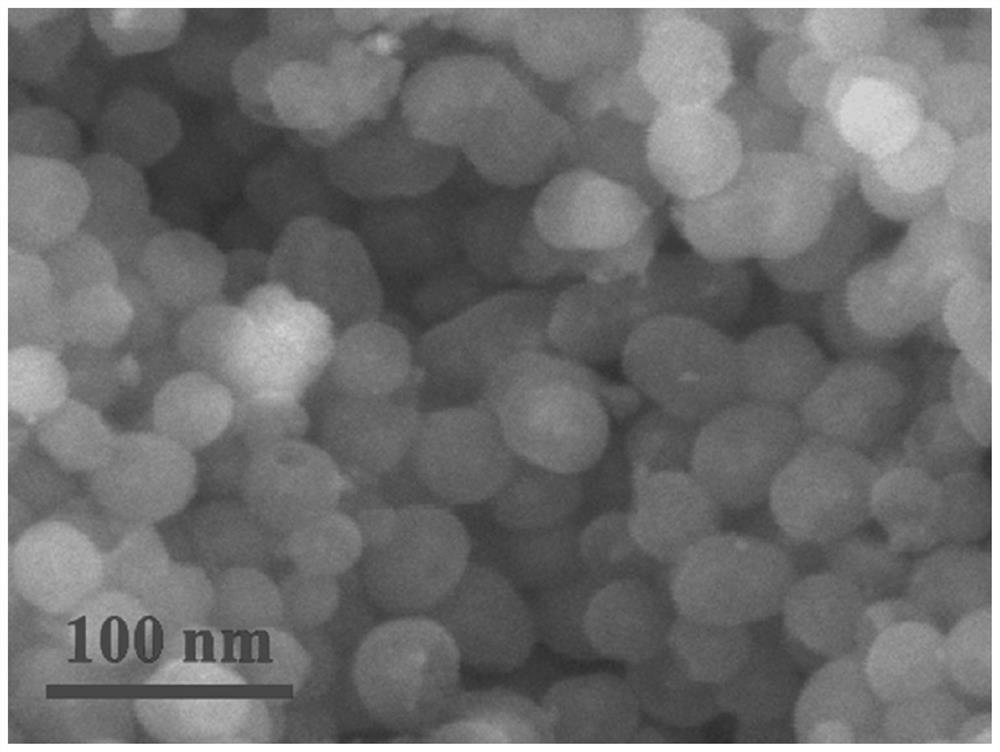

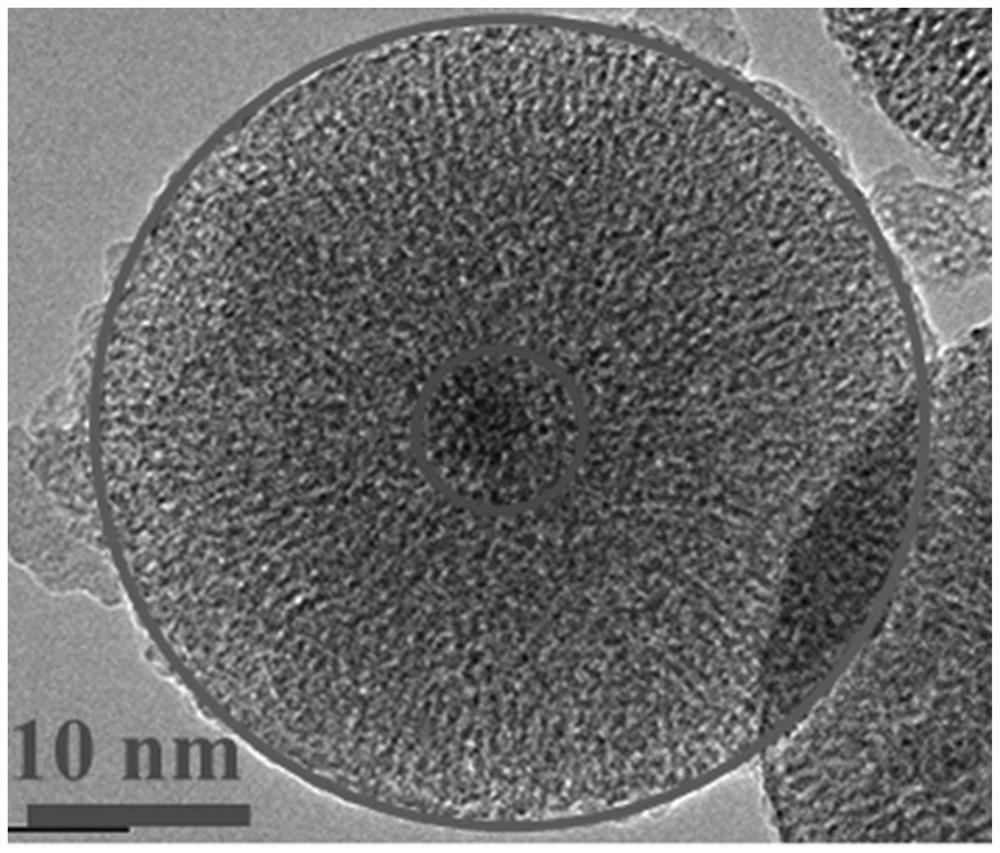

Preparation method of SiO2-coated Fe3O4 core-shell magnetic nanoparticles

A technology of magnetic nanoparticles and ferroferric oxide, which is applied in the field of composite materials, can solve the problems of uneven size, cumbersome and complicated synthesis methods, and easy agglomeration, and achieve the effect of avoiding many and complicated steps, good dispersion, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing silica-coated ferric oxide core-shell magnetic nanoparticles, which comprises the following steps:

[0034] (1) Preparation of microemulsion: Dissolve 0.05mol of Triton X-100 (manufacturer and model: Sigma-Aldrich.Inc.CAS 9002-93-1) in 100mL of organic solvent cyclohexane, stir to form a uniform water-in-oil microemulsion;

[0035] (2) Preparation of iron ferric oxide nanoparticles: add dropwise 4 mL of ferrous chloride tetrahydrate aqueous solution with a molar concentration of 0.6 mol / L in the water-in-oil microemulsion, stir and mix evenly, and then add 3mL of ammonia water with a molar concentration of 2.7mol / L, to obtain a uniformly dispersed iron ferric oxide nanoparticle microemulsion;

[0036] (3) Prepare the silica-coated shell: add 20 mL of pure orthosilicate (TEOS) dropwise to the microemulsion of iron ferric oxide nanoparticles as a silicon source, stir and mix evenly, and then add 15 mL of ammonia water with...

Embodiment 2

[0039] This embodiment provides a method for preparing silica-coated ferric oxide core-shell magnetic nanoparticles, which comprises the following steps:

[0040] (1) Prepare microemulsion: dissolve 0.05mol of Triton X-100 in 100mL organic solvent cyclohexane, stir to form a uniform water-in-oil microemulsion;

[0041] (2) Preparation of iron ferric oxide nanoparticles: in the water-in-oil microemulsion, dropwise add 4mL molar concentration of ferrous chloride tetrahydrate and ferric chloride hexahydrate mixed solution of 0.62mol / L, stir and mix evenly , then adding 3mL of ammoniacal liquor with a molar concentration of 2.7mol / L in the resulting mixed solution to obtain a uniformly dispersed iron ferric oxide nanoparticle microemulsion;

[0042](3) Preparation of silica-coated shell: Add 20 mL of pure orthosilicate (TEOS) dropwise to the microemulsion of iron ferric oxide nanoparticles as a silicon source, stir and mix evenly, and then add 14 mL of ammonia water with a molar ...

Embodiment 3

[0045] This embodiment provides a method for preparing silica-coated ferric oxide core-shell magnetic nanoparticles, which comprises the following steps:

[0046] (1) Prepare microemulsion: dissolve 0.05 mol of polyoxyethylene cetyl (4) ether in 100 mL of organic solvent cyclohexane, and stir to form a uniform water-in-oil microemulsion;

[0047] (2) Preparation of iron ferric oxide nanoparticles: add dropwise 4 mL of ferrous chloride tetrahydrate solution with a molar concentration of 0.60 mol / L in the water-in-oil microemulsion, stir and mix evenly, and then add 3mL of ammonia water with a molar concentration of 2.7mol / L, to obtain a uniformly dispersed iron ferric oxide nanoparticle microemulsion;

[0048] (3) Preparation of silica-coated shell: Add 20 mL of pure orthosilicate (TEOS) dropwise to the microemulsion of iron ferric oxide nanoparticles as a silicon source, stir and mix evenly, and then add 15 mL of ammonia water with a molar concentration of 2.7 mol / L is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com