High-voltage plasma water treatment system

A treatment system, plasma water technology, applied in water/sewage treatment, special compound water treatment, light water/sewage treatment, etc., can solve the problem of unable to install anode electrodes on heat dissipation pipes, achieve the effect of improving the effect and avoiding the effect of oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

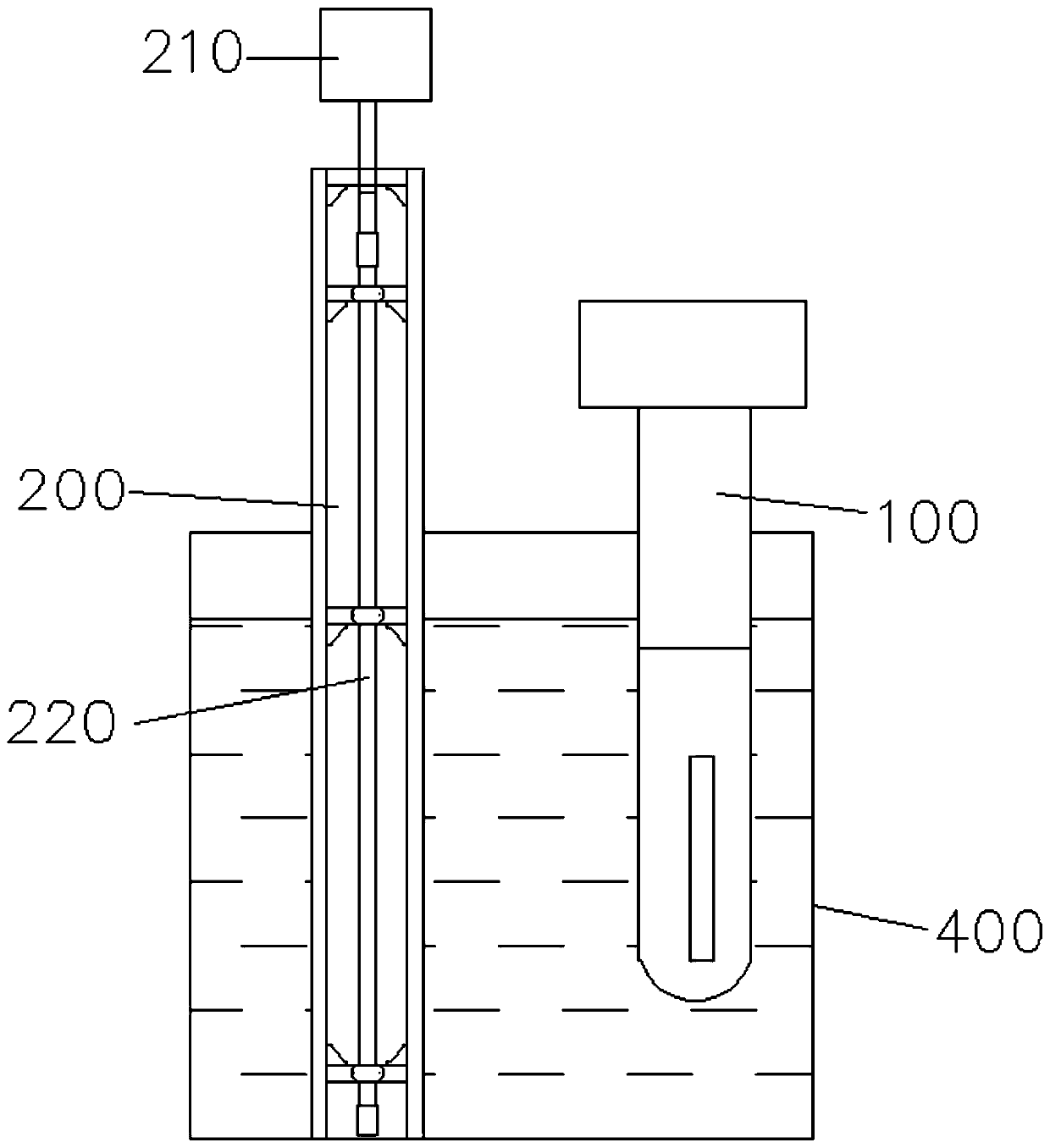

[0057] Refer to attached figure 1 Shown, a kind of high-pressure plasma water treatment system among the present embodiment comprises:

[0058] The first water treatment equipment 100, the first water treatment equipment 100 is used to release ultraviolet rays and ozone;

[0059] The second water treatment equipment 200, the second water treatment equipment 200 includes a high-voltage pack 210 and pipeline equipment 220, the high-voltage pack releases high-voltage electricity and transmits the high-voltage electricity to the sewage through the pipeline equipment, so that the sewage in the sewage Positive and negative ions are separated and arranged in an orderly manner;

[0060] The ultraviolet rays and ozone mutate the protein under the action of high voltage;

[0061] The number of the second water treatment equipment is greater than that of the first water treatment equipment, and the number of the first water treatment equipment and the number of the second water treatme...

Embodiment 2

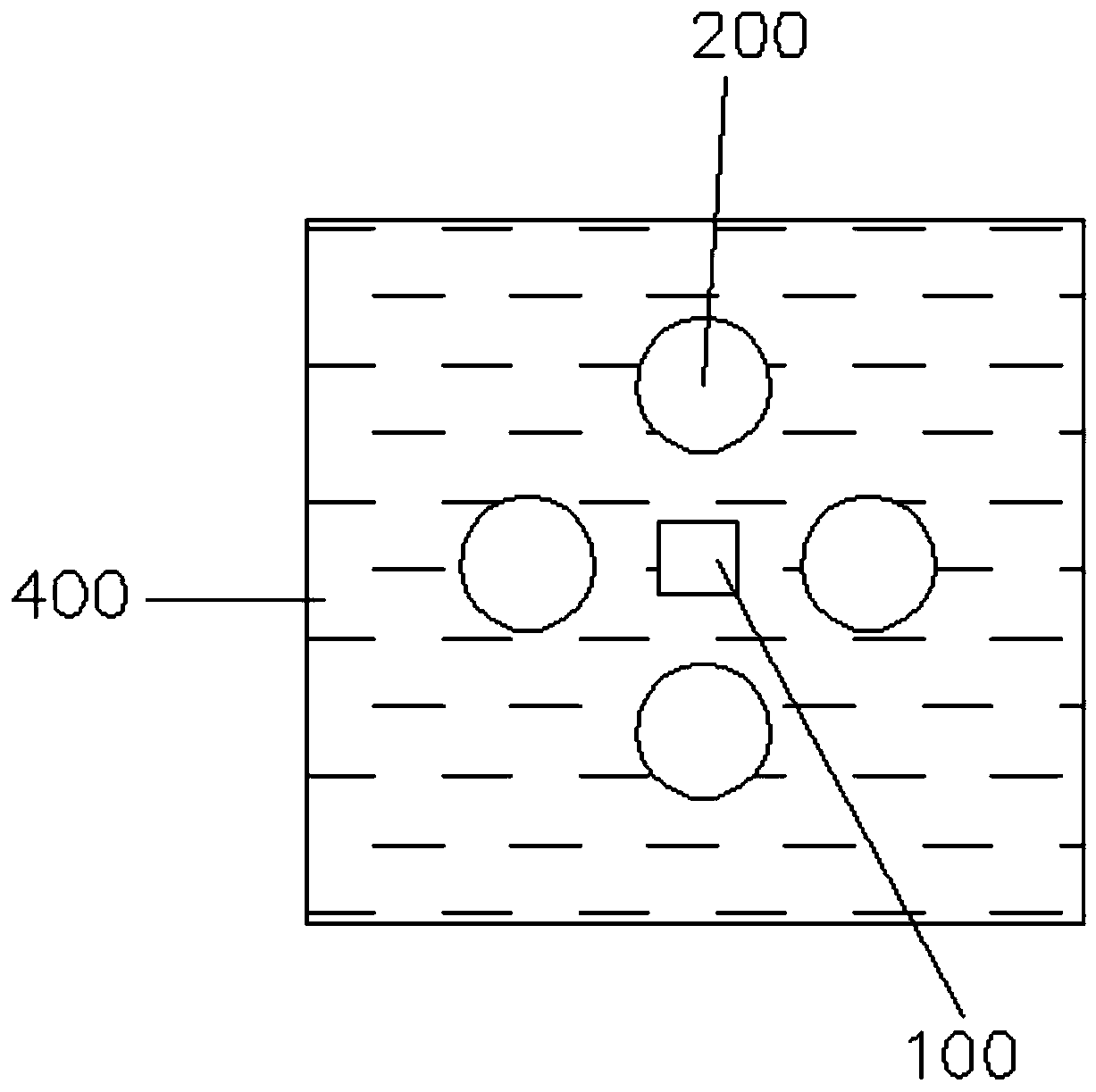

[0083] In this embodiment, on the basis of Embodiment 1, the positional spatial relationship and various installations between the first water treatment equipment 100 and the second water treatment equipment 200 are mainly introduced.

[0084] During installation, the second water treatment equipment 200 is arranged around the outer periphery of the first water treatment equipment 100 . In this embodiment, the first water treatment equipment releases ozone and ultraviolet rays, and in water treatment, siderophilic bacteria and hard scale are more urgently needed to be solved, so more second water treatment equipment 200 is needed. While the second water treatment equipment 200 surrounds the outer circumference of the first water treatment equipment 100, the second water treatment equipment 200 can solve the problem that the free ions on the outer circumference of the first water treatment equipment 100 are combined or oxidized and then affect the first water treatment equipment...

Embodiment 3

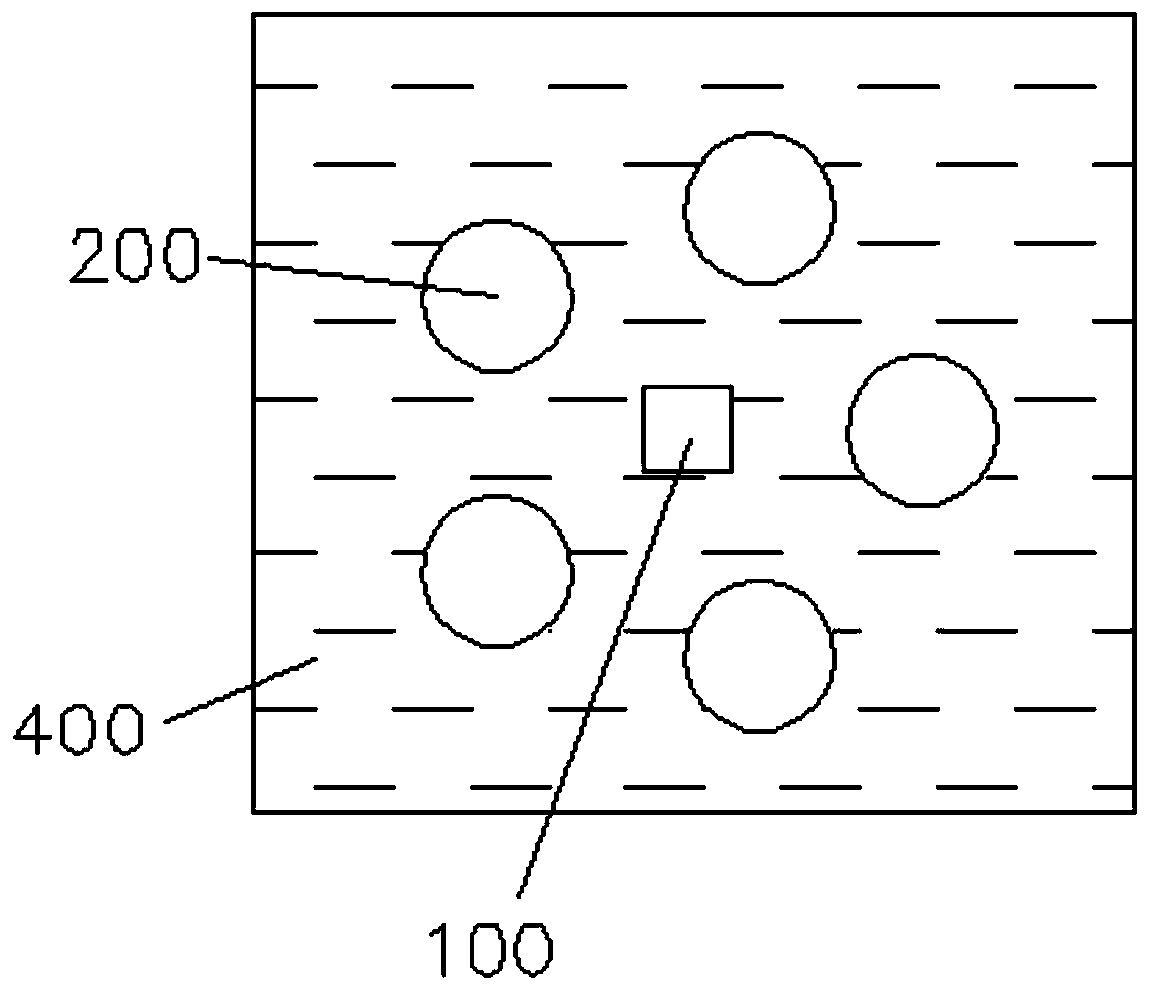

[0096] Refer to attached Figure 5 As shown, in this embodiment, the installation of the pipeline equipment 220 is mainly introduced.

[0097] In this embodiment, the pipeline equipment is specifically installed through the fixing frame 300 .

[0098] Specifically, the sewage to be treated is in the sewage pool 400, the fixed frame 300 is fixed on the bottom of the sewage pool 400, the fixed frame is provided with a fixed structure, and the pipeline equipment 220 is assembled on the fixed frame 300 through the fixed structure 310 superior.

[0099] In this technical solution, adding a grounded fixing frame can prevent electromagnetic coupling interference and improve the safety of the first water treatment equipment 100 and the second water treatment equipment 200 in use.

[0100] In this embodiment, the arrangement of the fixing frame 300 has the following conditions:

[0101] The first type, at this time, the sewage pool 400 is very small, and only one first water treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com