Magnesium phosphate cement repair mortar and preparation method thereof

A technology of magnesium phosphate cement and repair mortar, applied in the field of building materials, can solve problems such as increasing production cost, wasting time, reducing activity, etc., and achieves the effects of enhancing overall strength, delaying setting time, and prolonging induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

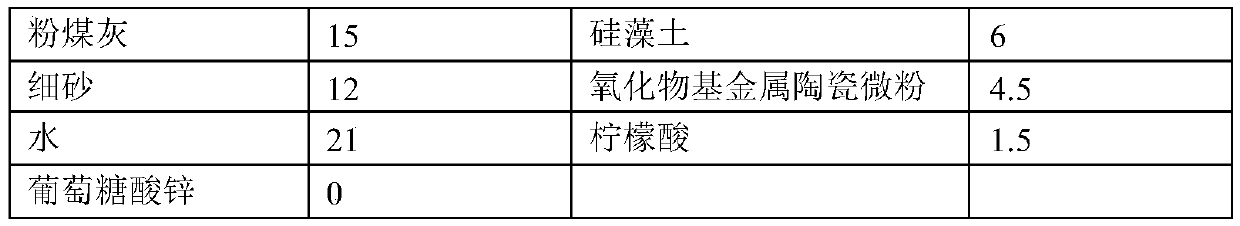

[0035] Embodiment 1, is a kind of magnesium phosphate cement repair mortar disclosed by the present invention and preparation method thereof, magnesium phosphate cement repair mortar comprises the following components by weight:

[0036] components parts by weight components parts by weight Potassium dihydrogen phosphate 28 copper gluconate 2 magnesium oxide 67 recycled concrete 10 fly ash 15 diatomite 8 fine sand 12 Oxide-based cermet powder 6 water 21 citric acid 1.5 Zinc gluconate 2.5

[0037] The particle size of potassium dihydrogen phosphate is 55um;

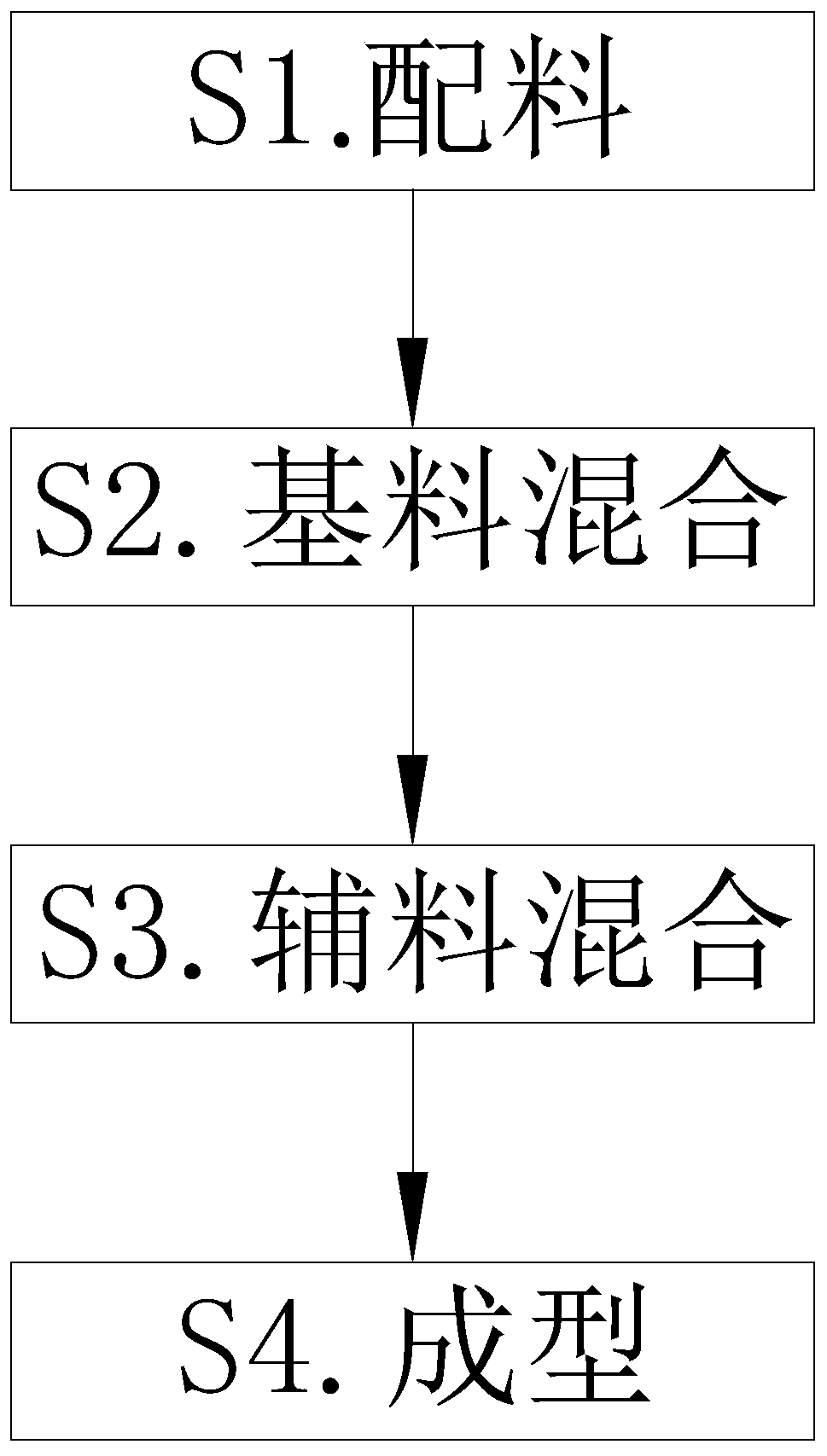

[0038] The preparation method of magnesium phosphate cement repair mortar specifically comprises the following steps:

[0039] S1. Batching: batching according to parts by weight;

[0040] S2. Base material mixing: firstly mix potassium dihydrogen phosphate, magnesium oxide, fly ash and fine sand at a low speed, the stirring speed is 35r / min, and t...

Embodiment 2

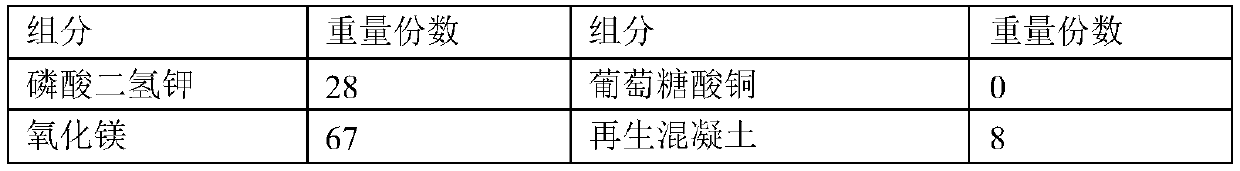

[0043] Embodiment 2, is a kind of magnesium phosphate cement repair mortar disclosed by the present invention and preparation method thereof, magnesium phosphate cement repair mortar comprises the following components by weight:

[0044] components parts by weight components parts by weight Potassium dihydrogen phosphate 35 copper gluconate 3 magnesium oxide 75 recycled concrete 8 fly ash 20 diatomite 6 fine sand 15 Oxide-based cermet powder 4.5 water 30 citric acid 2 Zinc gluconate 4

[0045] The particle size of potassium dihydrogen phosphate is 55um;

[0046] The preparation method of magnesium phosphate cement repair mortar is the same as embodiment 1.

Embodiment 3

[0047] Embodiment 3, is a kind of magnesium phosphate cement repair mortar disclosed by the present invention and preparation method thereof, magnesium phosphate cement repair mortar comprises the following components by weight:

[0048] components parts by weight components parts by weight Potassium dihydrogen phosphate 20 copper gluconate 1 magnesium oxide 60 recycled concrete 5 fly ash 10 diatomite 4 fine sand 10 Oxide-based cermet powder 3 water 12 citric acid 1 Zinc gluconate 1

[0049] The particle size of potassium dihydrogen phosphate is 55um;

[0050] The preparation method of magnesium phosphate cement repair mortar is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com