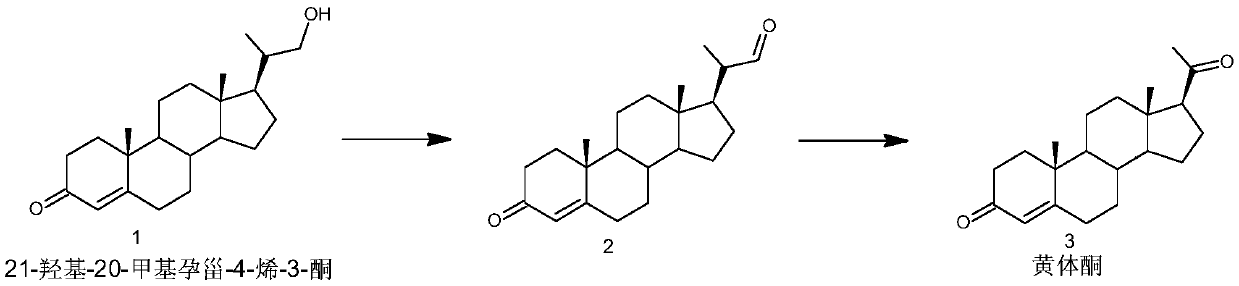

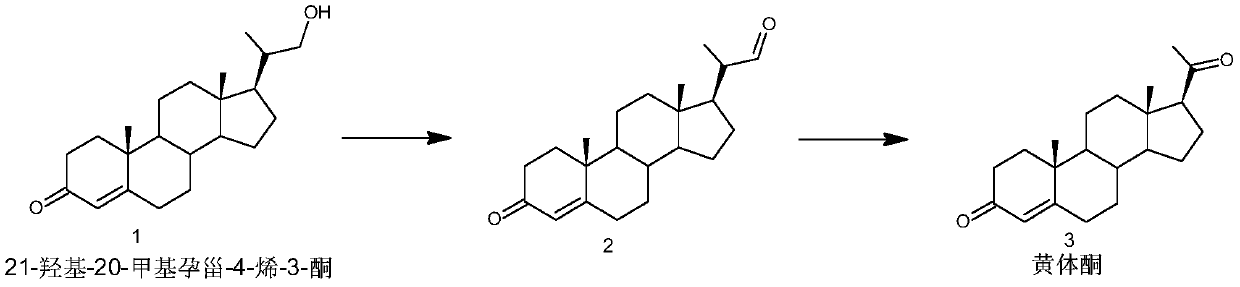

Preparation method of progesterone

A technology of progesterone and volume, applied in the direction of steroids, organic chemistry, etc., can solve the problems of low total yield, long reaction route, large pollution, etc., and achieve the effects of small environmental pollution, simple production operation, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Oxidation Reaction: Preparation of 20-formylpregn-4-en-3-one (2) 1

[0023] Add 25 grams of 21-hydroxy-20-methylpregn-4-en-3-one (1) and 150 milliliters of toluene into the reaction flask, stir and dissolve, then add 0.7 grams of TEMPO, 2 grams of potassium bromide, and 1.5 grams of carbonic acid Sodium hydrogen and 35 milliliters of water, 75 milliliters of mass concentrations are added dropwise and are 5% sodium hypochlorite aqueous solution, 10 ℃ of stirring reactions, after reaction is completed, add 25 milliliters of mass concentrations and be that 15% sodium thiosulfate aqueous solution quenches reaction, stand layering, The organic layer was washed with water until neutral, concentrated, analyzed by water, filtered and dried to obtain 23.5 g of 20-formylpregn-4-en-3-one (2).

Embodiment 2

[0024] Example 2 Oxidation Reaction: Preparation 2 of 20-formylpregn-4-en-3-one (2)

[0025] Add 25 grams of 21-hydroxy-20-methylpregn-4-en-3-one (1) and 150 milliliters of dichloromethane into the reaction flask, stir and dissolve, then add 0.5 grams of 4-hydroxy-TEMPO, 1.8 grams of bromine Potassium chloride, 1.5 grams of sodium bicarbonate and 40 milliliters of water, 70 milliliters of mass concentration is added dropwise and is 10% sodium hypochlorite aqueous solution, and -10 ℃ stirs reaction, after reaction is completed, add 70 milliliters of mass concentration and be that 5% sodium thiosulfate aqueous solution is quenched After the reaction, the layers were allowed to stand, and the organic layer was washed with water to neutrality, concentrated, water-analyzed, filtered, and dried to obtain 23.0 g of 20-formylpregn-4-en-3-one (2).

Embodiment 3

[0026] Example 3 Oxidation reaction: Preparation of 20-formylpregn-4-en-3-one (2) 3

[0027] Add 25 grams of 21-hydroxyl-20-methylpregn-4-en-3-one (1) and 150 milliliters of dichloroethane in the reaction flask, stir and dissolve, then add 0.8 grams of 4-hydroxyl-TEMPO, 2.0 grams of Potassium bromide, 1.8 grams of sodium bicarbonate and 45 milliliters of water are added dropwise with 75 milliliters of mass concentration of 15% sodium hypochlorite aqueous solution, and the reaction is stirred at 0°C. After the reaction is completed, adding 35 milliliters of mass concentration of 10% sodium thiosulfate aqueous solution is quenched After the reaction, the layers were allowed to stand, and the organic layer was washed with water until neutral, concentrated, water-analyzed, filtered, and dried to obtain 23.2 g of 20-formylpregn-4-en-3-one (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com