A kind of UV light curing high light transmittance optical adhesive and preparation method thereof

A technology of high light transmittance and optical glue, which is applied in the field of optical glue, can solve problems such as difficult heat dissipation, comprehensive performance of products that cannot meet performance requirements, and accidents easily, so as to ensure light transmittance and haze, and improve comprehensive performance , Improve the effect of sticking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 (E1): raw material formula sees Table 1

[0048] Table 1 Example 1 formula table

[0049] raw material BA HEA 2-EHA IBOA NDM HDDA AIBN 1173 001 Mass / g 20 10 60 5 0.1 5 0.3 0.1 0.9

[0050] Pretreatment of raw materials: butyl acrylate (BA), hydroxyethyl acrylate (HEA), isooctyl acrylate (2-EHA), isobornyl acrylate (IBOA) and reactive diluent HDDA were vacuum dehydrated for 1 h before use, oil The bath temperature is the same as their respective boiling points, and dodecyl mercaptan (NDM) and azobisisobutyronitrile (AIBN) are placed in a vacuum oven for 12 hours for use. Put the mixed solution of 40wt% BA, 2-EHA and NDM after pretreatment into a 250ml four-neck flask, after heating up to 80°C, dissolve AIBN in another 60wt% mixed solution of BA, 2-EHA and NDM And all the HEA, IBOA, HDDA solutions, then add 1173, 001, shake well, add to the polytetrafluoroethylene constant pressure dropping funnel and start to drop...

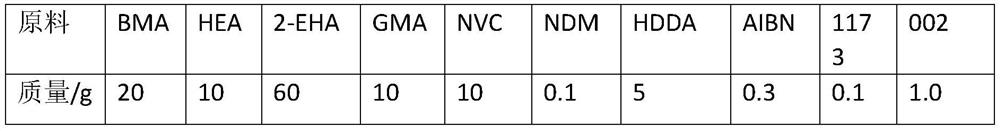

Embodiment (E2

[0051] Embodiment (E2): raw material formula sees Table 2

[0052] Table 2 Example 2 formula table

[0053] raw material HEA 2-EHA MMA t-BA NDM HDDA AIBN 1173 002 Mass / g 10 60 15 10 0.1 5 0.3 0.1 1.3

[0054] Pretreatment of raw materials: tert-butyl acrylate (t-BA), hydroxyethyl acrylate (HEA), isooctyl acrylate (2-EHA), methyl methacrylate (MMA) and reactive diluent HDDA are vacuumed before use Dehydration was carried out for 1 hour, the temperature of the oil bath was the same as their respective boiling points, and dodecyl mercaptan (NDM) and azobisisobutyronitrile (AIBN) were placed in a vacuum oven for 12 hours before use.

[0055] Put the mixed solution of 30% t-BA, 2-EHA and NDM after pretreatment into a 250ml four-necked flask, and after raising the temperature to 80°C, dissolve AIBN in another 70% of t-BA, 2-EHA and Add 1173 and 002 to the mixed solution of NDM and the mixed solution of HEA, MMA, and HDDA, shake well, add ...

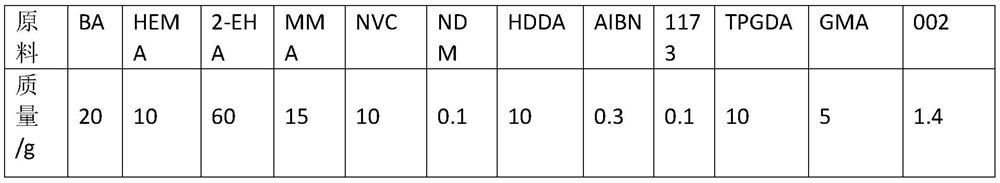

Embodiment 3

[0056] Embodiment 3 (E3): raw material formula sees Table 3

[0057] Table 3 Example 3 formula table

[0058] raw material BMA HEA 2-EHA t-BA DMAA NDM HDDA AIBN 1173 001 Mass / g 20 10 60 10 10 0.1 5 0.3 0.1 1.4

[0059] Raw material pretreatment: butyl methacrylate (BA), hydroxyethyl acrylate (HEA), isooctyl acrylate (2-EHA), tert-butyl acrylate (t-BA), N,N-dimethylacrylamide (DMAA) and reactive diluent HDDA were vacuum dehydrated for 1 h before use, and the temperature of the oil bath was the same as their respective boiling points. Dodecylmercaptan (NDM) and azobisisobutyronitrile AIBN were placed in a vacuum oven for 12 h before use.

[0060] Put the mixed solution of pretreated 60% BMA, 2-EHA and NDM into a 250ml four-neck flask, after the temperature was raised to 80°C, AIBN was dissolved in another 40% mixed solution of BMA, 2-EHA and NDM and Into the mixed solution of HEA, t-BA, HDDA, DMAA, then add 1173, 001, shake well, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com