Lithium silicate modified solid polymer electrolyte material and preparation method thereof

A technology of solid polymer and lithium silicate, which is applied in the direction of solid electrolyte, composite electrolyte, non-aqueous electrolyte, etc., can solve the problem of low ionic conductivity, achieve the goal of improving electrolyte performance, reducing cost, comprehensive performance and application prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

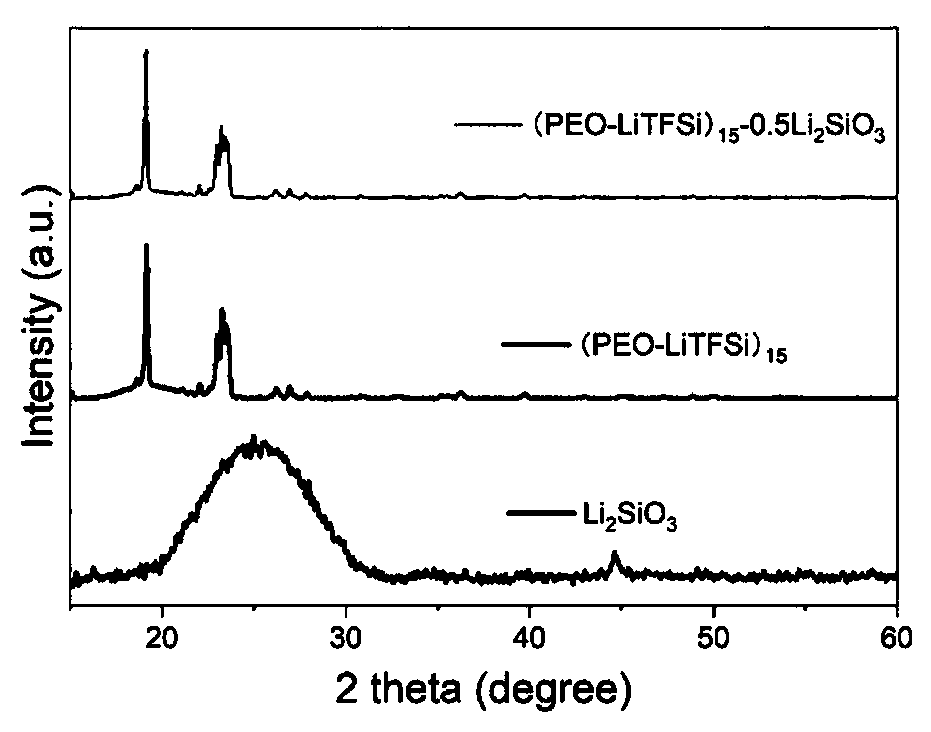

[0049] Step 1: LiTFSi, PEO (M w =9×10 5 gmol -1 ), the ball-milled lithium silicate was dried in a vacuum oven at 50°C for 24 hours, and placed in a glove box for subsequent use.

[0050] Step 2: Weigh the PEO, LiTFSi and lithium silicate obtained by drying in step 1 in proportion. The quality of lithium silicate is 5%wt of the total mass of the polymer substrate and lithium salt, and control EO: Li + The molar ratio is 15:1. Put the weighed drug into a beaker, add acetonitrile (the mass is 9 times the total mass of the weighed drug), and stir vigorously at room temperature for 12 hours.

[0051] Step 3: Pour the obtained solution onto a polytetrafluoroethylene plate, let it advect naturally, and evaporate the solvent in a fume hood at room temperature.

[0052] Step 4: tear off the film and place it in a polytetrafluoroethylene petri dish, and dry it in a vacuum oven at 60°C for 12 hours to further remove the solvent to obtain a PEO-based solid polymer electrolyte with lit...

Embodiment 2

[0054] Step 1: LiTFSi, PEO (M w =9×10 5 gmol -1 ), the ball-milled lithium silicate was dried in a vacuum oven at 50°C for 24 hours, and placed in a glove box for subsequent use.

[0055] Step 2: Weigh the PEO, LiTFSi and lithium silicate obtained by drying in step 1 in proportion. The quality of lithium silicate is 10%wt of the total mass of the polymer substrate and lithium salt. Control EO: Li + The molar ratio is 15:1. Put the weighed drug into a beaker, add acetonitrile (the mass is 9 times the total mass of the weighed drug), and stir vigorously at room temperature for 12 hours.

[0056] Step 3: Pour the obtained solution onto a polytetrafluoroethylene plate, let it advect naturally, and evaporate the solvent in a fume hood at room temperature.

[0057] Step 4: tear off the film and place it in a polytetrafluoroethylene petri dish, and dry it in a vacuum oven at 60°C for 12 hours to further remove the solvent to obtain a PEO-based solid polymer electrolyte with lithiu...

Embodiment 3

[0059] Step 1: LiTFSi, PEO (M w =9×10 5 gmol -1 ), the ball-milled lithium silicate was dried in a vacuum oven at 50°C for 24 hours, and placed in a glove box for subsequent use.

[0060] Step 2: Weigh the PEO, LiTFSi and lithium silicate obtained by drying in step 1 in proportion. The quality of lithium silicate is 15%wt of the total mass of the polymer substrate and lithium salt. Control EO: Li + The molar ratio is 15:1. Put the weighed drug into a beaker, add acetonitrile (the mass is 9 times the total mass of the weighed drug), and stir vigorously at room temperature for 12 hours.

[0061] Step 3: Pour the obtained solution onto a polytetrafluoroethylene plate, let it advect naturally, and evaporate the solvent in a fume hood at room temperature.

[0062] Step 4: tear off the film and place it in a polytetrafluoroethylene petri dish, and dry it in a vacuum oven at 60°C for 12 hours to further remove the solvent to obtain a PEO-based solid polymer electrolyte with lithiu...

PUM

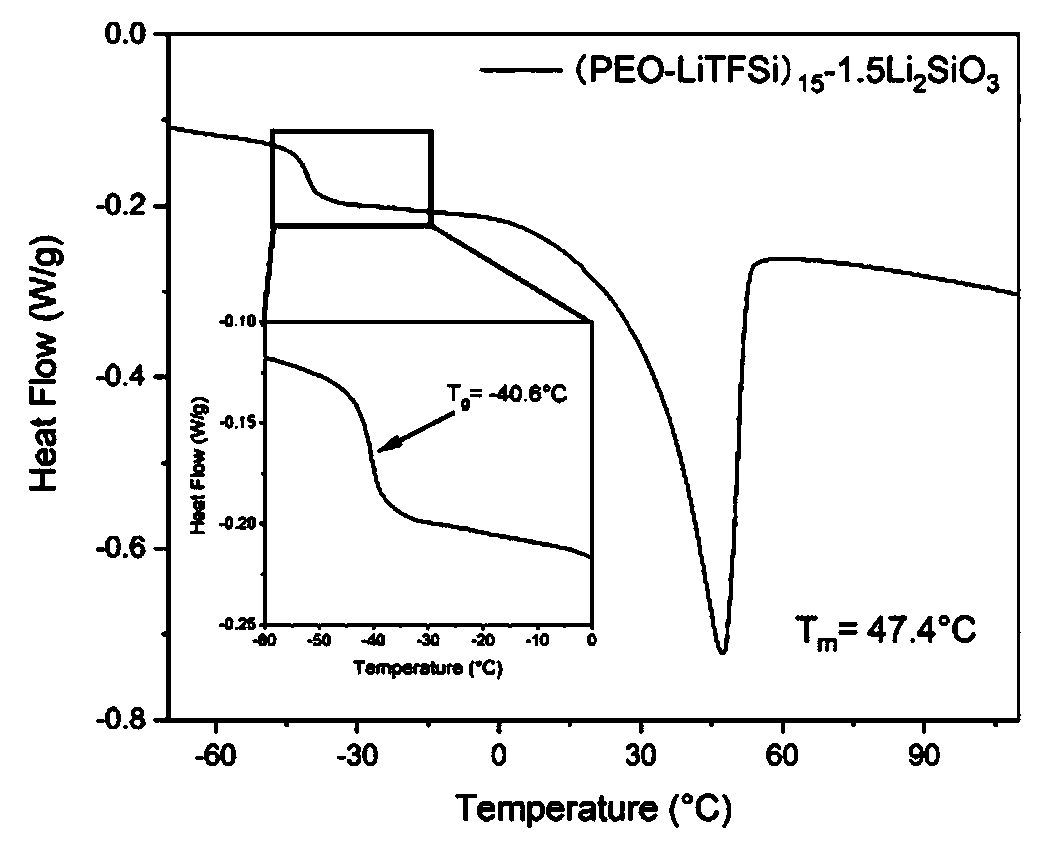

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com