Organic silicon electrolyte as well as preparation method and application thereof

A technology of organosilicon and electrolytes, which is applied in composite electrolytes, electrolyte immobilization/gelation, circuits, etc., and can solve problems such as unsatisfactory mechanical properties, large interface impedance, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

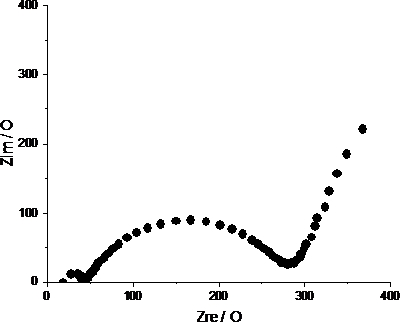

Embodiment 1

[0044] This embodiment includes the following specific steps:

[0045] S1. Preparation of organosilicon electrolyte matrix: in a 250mL dry four-necked flask with a thermometer, a condenser, and a stirrer fed with argon at the same time, 0.25mol of allyl polyethylene glycol (molecular weight 400) and 0.3mol of HSi (OC 2 H 5 ) 3 Add to the bottle, stir and heat up to 60 o C, drop 0.4mL of chloroplatinic acid solution, continue to react for 2h and then drop to room temperature and then discharge, remove unreacted HSi (OC) by vacuum distillation 2 H 5 ) 3 , to obtain the hydrosilylation product. Mix 0.1 mol of the hydrosilylation product, 0.1 mol of triethylamine and 50 mL of tetrahydrofuran, and then add it to a flask with a thermometer, a condenser, a stirrer, and a constant pressure funnel, and dissolve 0.12 mol of methacryloyl chloride in 30 mL of tetrahydrofuran. , pour it into a constant pressure funnel, stir and control the temperature at 50 °C, add it to the flask fo...

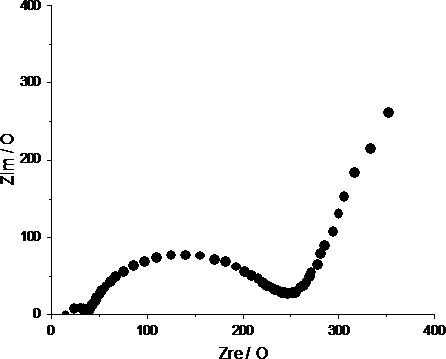

Embodiment 2

[0049] This embodiment includes the following specific steps:

[0050] S1. Preparation of organosilicon electrolyte matrix: in a 250mL dry four-necked flask with a thermometer, a condenser, and a stirrer fed with argon at the same time, 0.25mol of allyl polyethylene glycol (molecular weight 600) and 0.3mol of HSi (OCH 3 ) 3 Add to the bottle, stir and heat up to 60 o C, drop 0.4mL of chloroplatinic acid solution, continue to react for 2h and then drop to room temperature and then discharge, remove unreacted HSi (OCH) by vacuum distillation 3 ) 3 , to obtain the hydrosilylation product. Mix 0.1 mol of the hydrosilylation product, 0.1 mol of triethylamine and 50 mL of tetrahydrofuran, and then add it to a flask with a thermometer, a condenser, a stirrer, and a constant pressure funnel, and dissolve 0.12 mol of methacryloyl chloride in 30 mL of tetrahydrofuran. , pour it into a constant pressure funnel, stir and control the temperature at 50 °C, add it to the flask for about...

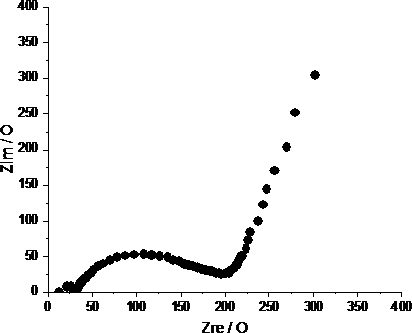

Embodiment 3

[0054] This embodiment includes the following specific steps:

[0055] S1. Preparation of organosilicon electrolyte matrix: in a 250mL dry four-necked flask with a thermometer, a condenser, and a stirrer fed with argon at the same time, 0.25mol of allyl polyethylene glycol (molecular weight 600) and 0.3mol of HSi (OCH 3 ) 3 Add to the bottle, stir and heat up to 60 o C, drop 0.4mL of chloroplatinic acid solution, continue to react for 2h and then drop to room temperature and then discharge, remove unreacted HSi (OCH) by vacuum distillation 3 ) 3 , to obtain the hydrosilylation product. Mix 0.1 mol of the hydrosilylation product, 0.1 mol of triethylamine and 50 mL of tetrahydrofuran, and then add it to a flask with a thermometer, a condenser, a stirrer, and a constant pressure funnel, and dissolve 0.12 mol of methacryloyl chloride in 30 mL of tetrahydrofuran. , pour it into a constant pressure funnel, stir and control the temperature at 50 °C, add it to the flask for about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com