Preparation methods for porous nano antibacterial particles and composite hollow membrane and composite hollow membrane

A technology of antibacterial particles and nanoparticles, which is applied in the field of membrane separation, can solve the problems of large membrane flux, large water flux, and anti-bacterial pollution on the antibacterial performance of the membrane, so as to reduce membrane operation and maintenance costs, prolong service life, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

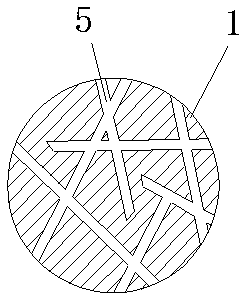

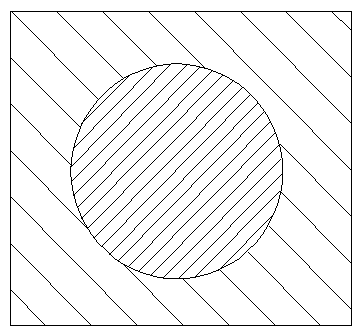

[0039] The invention provides a method for preparing porous copper-clad titanium dioxide nanometer antibacterial particles, which comprises:

[0040] Put titanium tetrachloride dropwise into an ice-water bath while vigorously stirring, add ammonium sulfate and concentrated hydrochloric acid aqueous solutions dropwise into the obtained titanium tetrachloride aqueous solution, and stir at a temperature below 15°C to obtain a mixture. The mixture was heated up to 93°C to 97°C and kept warm for 1 hour, then added concentrated ammonia water to adjust the pH value to 5-7, cooled to room temperature, and stood still for 12 hours to obtain titanium dioxide sol. Add 15% to 110% by weight of titanium tetrachloride β-cyclodextrin into the titanium dioxide sol, and stir vigorously at the same time, adjust the pH value to 5-6, and continue stirring for 1 hour to obtain the titanium dioxide glue. Put the titanium dioxide glue solution into a hydrothermal reaction kettle, and conduct a hydro...

Embodiment 1

[0049] 1. Preparation of Porous Copper-coated Titanium Dioxide Nanoparticles

[0050] Using titanium tetrachloride as the precursor, 100ml of TiCl 4 Drop into pure water. The aqueous solution dissolved in ammonium sulfate and concentrated hydrochloric acid is added dropwise to the obtained titanium tetrachloride aqueous solution, and the mixture is stirred, and the temperature is controlled below 15°C during the mixing process. After heating the mixture to 95°C and keeping it warm for 1 hour, add concentrated ammonia water, adjust the pH value to about 6, cool to room temperature, let it stand for 12 hours, and then wash with pure water, precipitate, and remove the supernatant for multiple washings. Under the condition of vigorous stirring, β-cyclodextrin was added to the cleaned titanium dioxide sol, and the amount of β-cyclodextrin added was 90% of titanium tetrachloride; the pH value of the solution was adjusted to 5-6, Continue to stir for 1h, put it into a hydrothermal ...

Embodiment 0 and 2-7

[0062] The same steps as in Example 1, except that the content of porous copper-clad titanium dioxide nano-antibacterial particles added to the casting solution is changed, and the ratios to PVDF are: 0%, 1.0%, 2.0%, 3.0%, 3.5% , 4.0%, 5.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com