A kind of ag load wo 3 Nanofiber-porous carbon photocatalytic material and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

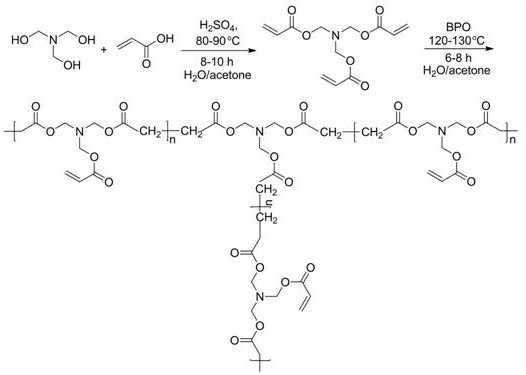

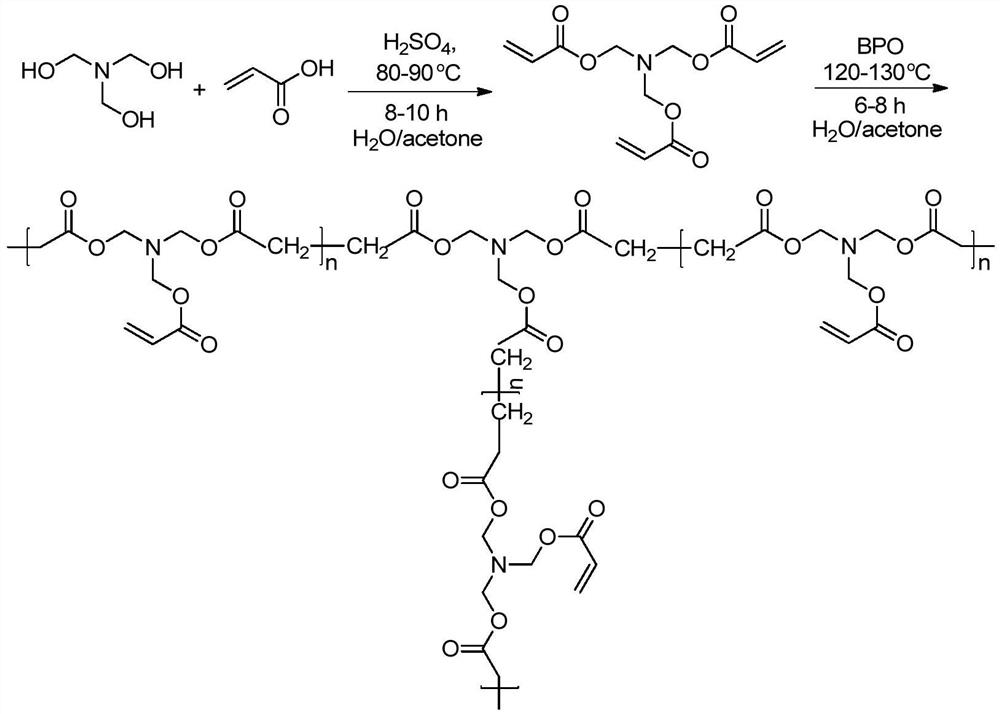

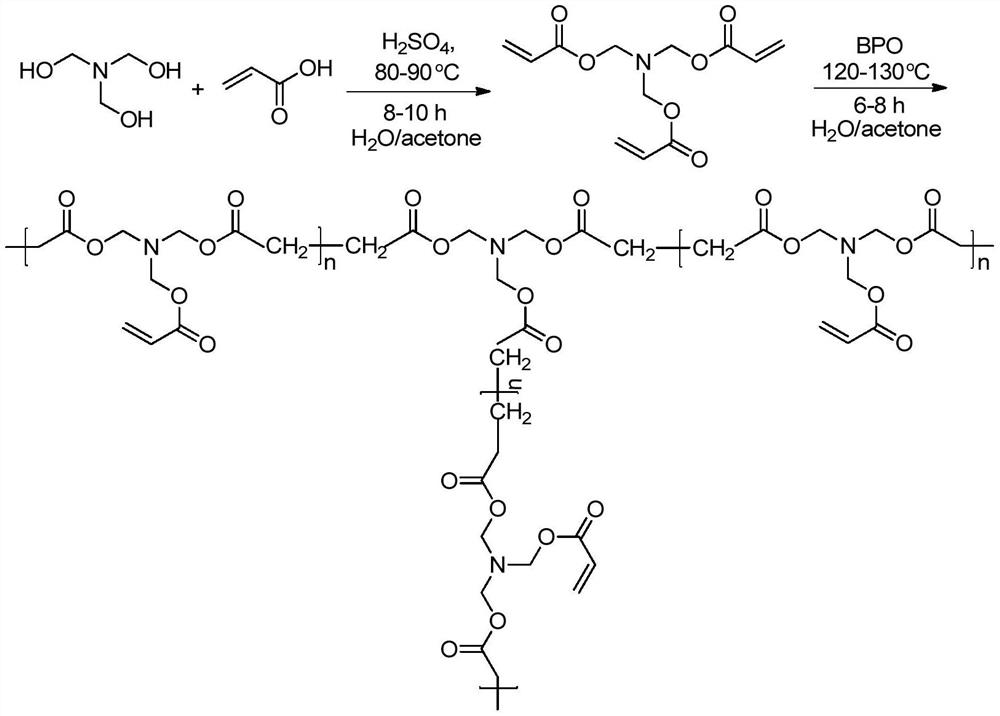

[0024] Hyperbranched polyacrylate preparation method comprises the following steps:

[0025] (1) Pass high-purity N into the reaction flask 2 , add an appropriate amount of distilled water and acetone as a mixed solvent, the volume ratio of the two is 2-4:1, then add triethanolamine and acrylamide in turn, stir evenly, add catalyst concentrated sulfuric acid, adjust the pH to 11-12, and heat the reaction bottle to 80-90°C, stir and reflux at a constant speed for 8-12 hours, then slowly add the initiator dibenzoyl peroxide (BPO), triethanolamine, acrylamide, concentrated sulfuric acid and the initiator dibenzoyl peroxide (BPO) four The molar ratio of the substance is 1:30-40:0.1-0.3:1-2, the solution is transferred into the polytetrafluoroethylene hydrothermal reactor, and placed in the reactor heating box, heated to 120-130 ℃, react for 6-8h, cool the solution to room temperature, filter to remove the solvent, wash the solid product with appropriate amount of distilled water ...

Embodiment 1

[0032] (1) Preparation of hyperbranched polyacrylate 1: Pass high-purity N into the reaction bottle 2 , add an appropriate amount of distilled water and acetone as a mixed solvent, the volume ratio of the two is 2:1, then add triethanolamine and acrylamide in sequence, stir evenly, add catalyst concentrated sulfuric acid, adjust the pH to 11, and heat the reaction bottle to 80 °C, Stirring and reflux reaction at a uniform speed for 8h, then slowly add initiator dibenzoyl peroxide (BPO), the amount mol ratio of the four of triethanolamine, acrylamide, vitriol oil and initiator dibenzoyl peroxide (BPO) is 1:30:0.1:1, transfer the solution into a polytetrafluoroethylene hydrothermal reactor, and place it in the reactor heating box, heat to 120°C, react for 6h, cool the solution to room temperature, filter to remove the solvent, and then The solid product was washed with an appropriate amount of distilled water and absolute ethanol, and fully dried to obtain hyperbranched polyacry...

Embodiment 2

[0037] (1) Preparation of hyperbranched polyacrylate 2: Pass high-purity N into the reaction bottle 2 , add an appropriate amount of distilled water and acetone as a mixed solvent, the volume ratio of the two is 2:1, then add triethanolamine and acrylamide in sequence, stir evenly, add catalyst concentrated sulfuric acid, adjust the pH to 11, and heat the reaction bottle to 80 °C, Stirring and reflux reaction at a uniform speed for 8h, then slowly add initiator dibenzoyl peroxide (BPO), the amount mol ratio of the four of triethanolamine, acrylamide, vitriol oil and initiator dibenzoyl peroxide (BPO) is 1:30:0.1:1, transfer the solution into a polytetrafluoroethylene hydrothermal reactor, and place it in the reactor heating box, heat to 120°C, react for 6h, cool the solution to room temperature, filter to remove the solvent, and then The solid product was washed with an appropriate amount of distilled water and absolute ethanol, and fully dried to obtain hyperbranched polyacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com