Composite anti-corrosion and anti-mildew agent for bio-based adhesive and preparation method of composite anti-corrosion and anti-mildew agent

A technology of anti-corrosion and anti-fungal agents and adhesives, which is applied in the field of anti-corrosion and anti-mold agents, can solve the problems of narrow antibacterial spectrum range and large dosage, achieve the effect of shortening the reaction time, reducing the dosage, and helping the equipment to prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

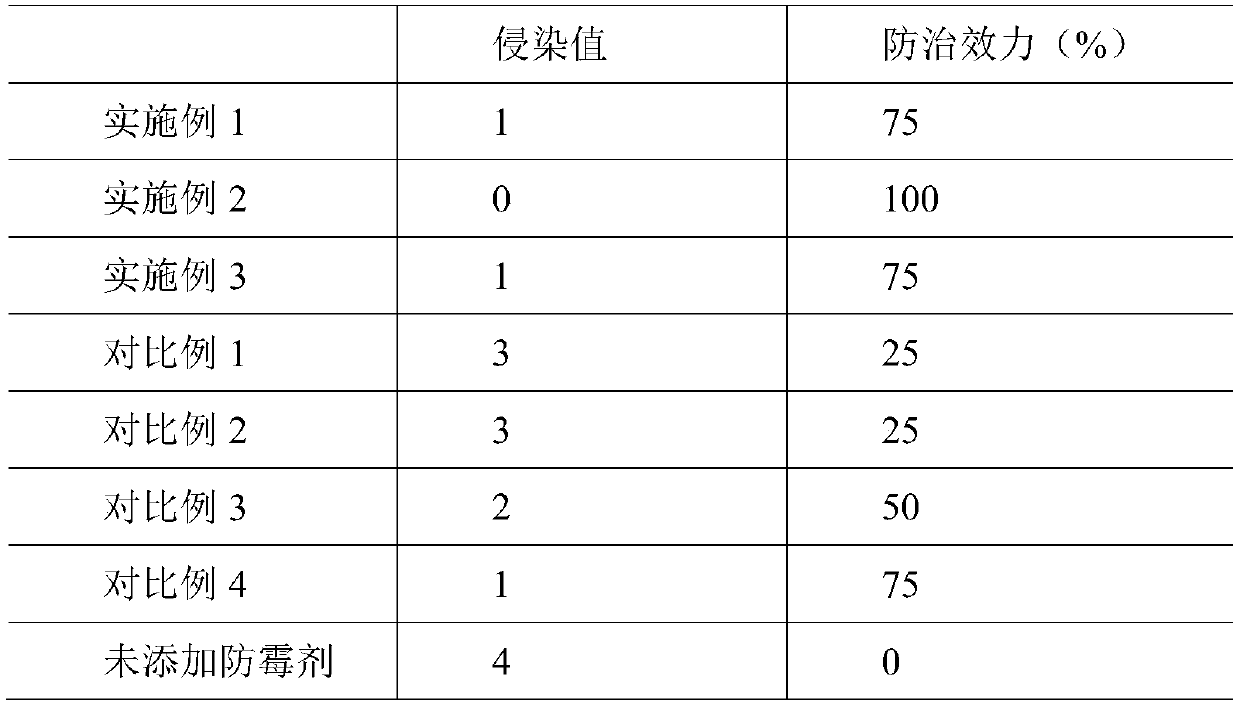

Examples

Embodiment 1

[0025] Preparation: 100 parts of calcium silicate, 40 parts of calcium oxide, 4 parts of zinc oxide, 2 parts of copper oxide, 0.5 parts of silver oxide, and 240 parts of borax. Prepare according to the following steps:

[0026] (a) Pre-reaction: Add borax and silicate to 1000 parts of water, then sequentially add calcium oxide, zinc oxide, silver oxide, and copper oxide, control the temperature to about 45°C, and continue to stir for 1 hour to obtain a pre-reacted slurry;

[0027] (b) Wet grinding: add the above-mentioned pre-reaction slurry to a wet grinding machine for 60 minutes;

[0028] (c) Dehydration washing: centrifuge the above-mentioned qualified slurry and wash it with clean water twice; the water phase is returned to the ingredients;

[0029] (d) Drying treatment: Dry the washed solid material in a dryer at a temperature of 150°C for 1 hour to obtain a powdered product with a particle size D50 of 12 microns, and it contains B 2 O 3 21.84%, ZnO 1.52%, CuO 0.72%, Ag 2 O is 0....

Embodiment 2

[0031] Preparation: 100 parts of calcium silicate, 60 parts of calcium oxide, 6 parts of zinc oxide, 3 parts of copper oxide, 1 part of silver oxide, 260 parts of borax, and then prepare according to the steps of Example 1, that is, the particle size D50 is 15 microns Powdered product, and it contains B 2 O 3 25.03%, ZnO 1.67%, CuO 0.85%, Ag 2 O is 0.28%.

Embodiment 3

[0033] Same as Example 1, but 500 parts of dissolved water are taken to obtain a powdered product with a particle size D50 of 16 microns, and it contains B 2 O 3 22.14%, ZnO 1.54%, CuO 0.73%, Ag 2 O is 0.18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com