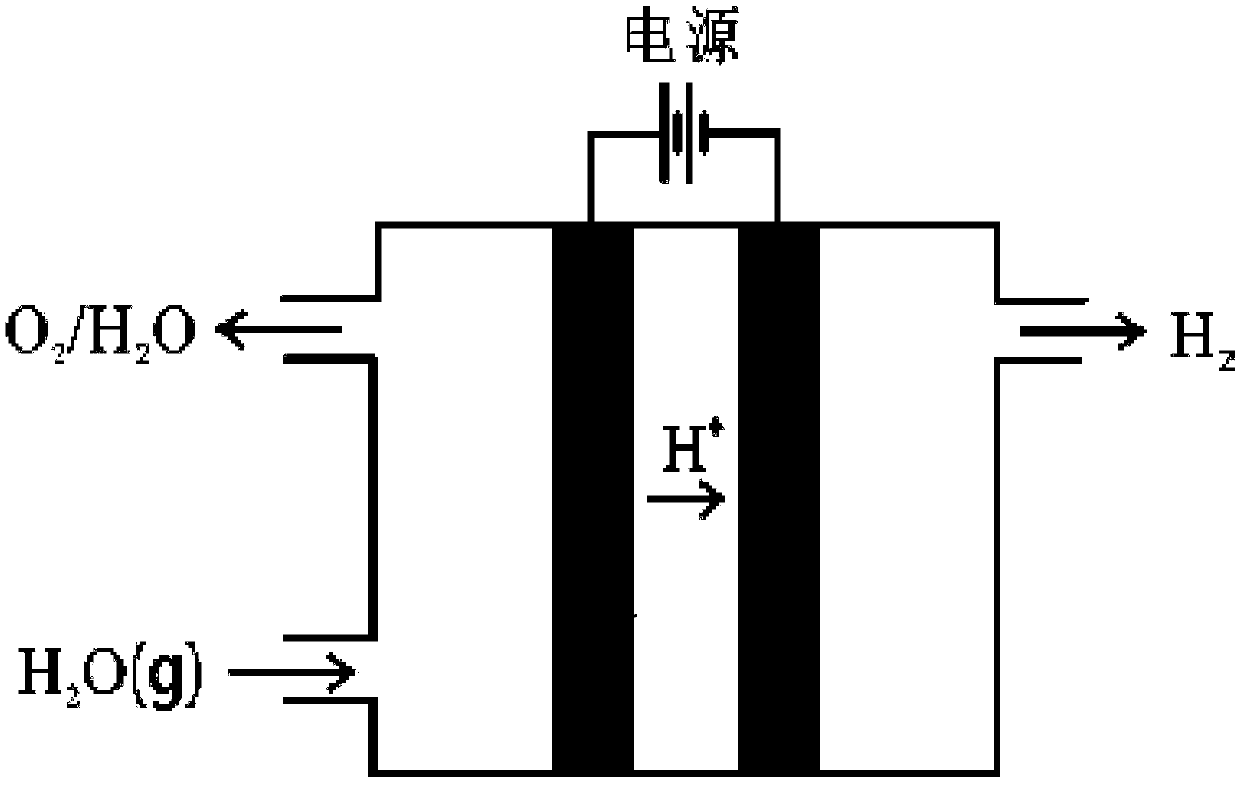

Method for producing hydrogen through electrolysis of water vapor

A water vapor and hydrogen technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of multi-energy, complex mass transfer and heat transfer process, difficult to start and stop quickly, etc., to reduce energy consumption, simplify electrolysis devices, improve The effect of electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 100g persulfonic acid resin solution (5wt%, purchased from DuPont Company, the same below) was stirred in a three-necked flask to make it uniformly dispersed, and then 20g zirconium nitrate solution (10wt%) was gradually added dropwise at room temperature (25° C.), Stir for 1 hour, after dispersing evenly, add it into a polytetrafluoroethylene mold plate to form a solution film, dry it in a vacuum oven at 80°C for 10 hours, take it out, put it in a 10M phosphoric acid solution, and keep it at 60°C for 24 hours, the film After taking it out, remove moisture in a vacuum oven at 80°C to obtain the desired composite cation exchange membrane of inorganic zirconium phosphate and perfluorosulfonic acid resin.

[0046] The ion exchange membrane adopts the above-mentioned cation exchange membrane, the cathode catalyst and the anode catalyst are both Pt, and 130°C water vapor is introduced, and a 2.2V DC voltage is applied, and the water vapor generates H under the action of the c...

Embodiment 2

[0048] Stir 100g of persulfonic acid resin solution (5wt%) in a three-necked flask to disperse it evenly, then gradually drop 1.5g of dimethylimidazolium hexafluorophosphate ionic liquid (purity>99%) at room temperature (25°C) Add it, stir for 1 hour, and disperse evenly, add it into a polytetrafluoroethylene mold plate to form a solution film, and dry it in a vacuum oven at 80°C for 10 hours to obtain the desired imidazole-based ionic liquid and perfluorosulfonic acid resin composite cation exchange membrane.

[0049] The ion exchange membrane adopts the above-mentioned cation exchange membrane, the cathode catalyst and the anode catalyst are both Pt, and 150°C water vapor is introduced, and a 2.2V DC voltage is applied, and the water vapor generates H under the action of the cathode catalyst. 2 , under the action of the anode catalyst to produce O 2 , energy consumption is 4.2kWh / Nm 3 .

Embodiment 3

[0051] In a three-necked flask, 10g of polybenzimidazole (purchased from Suzhou Pinyu Co., Ltd.) was dissolved in a dimethylacetamide solvent to form a solution (5wt%), stirred to disperse it evenly, and then at room temperature (25° C.) Gradually drop 8g of phosphoric acid solution (50wt%), stir for 1h, and disperse evenly, add it into a polytetrafluoroethylene mold to form a solution film, and dry it in a vacuum oven at 80°C for 10h to obtain the required phosphoric acid and polytetrafluoroethylene. Benmidazole composite cation exchange membrane.

[0052] The ion-exchange membrane adopts the above-mentioned cation-exchange composite membrane, the cathode catalyst and the anode catalyst are both Pt, and 200°C water vapor is introduced, and a 2.2V DC voltage is applied, and the water vapor generates H under the action of the cathode catalyst. 2 , under the action of the anode catalyst to produce O 2 , energy consumption is 3.8kWh / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com