Elastic fiber melt-blown nonwoven fabric and preparation method thereof

A technology of melt-blown non-woven fabrics and elastic fibers, applied in the directions of non-woven fabrics, textiles and papermaking, etc. problem, to achieve the effect of excellent anti-adhesion ability, improved mechanical properties, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a kind of preparation method of elastic fiber melt-blown nonwoven fabric, comprises the steps:

[0035] S1. Mix polypropylene-based elastomer slices, ultra-high molecular weight polyethylene slices, and nano-silicon carbide and dry them until the moisture content is below 150ppm. Melt and blend them through a twin-screw extruder at a melting temperature of 200-230°C to form a skin layer material melt;

[0036] S2. Mix thermoplastic polyurethane elastomer slices and compatibilizers and dry until the moisture content is below 150ppm, melt and blend through a twin-screw extruder at a melting temperature of 180-240°C to form a core layer material melt;

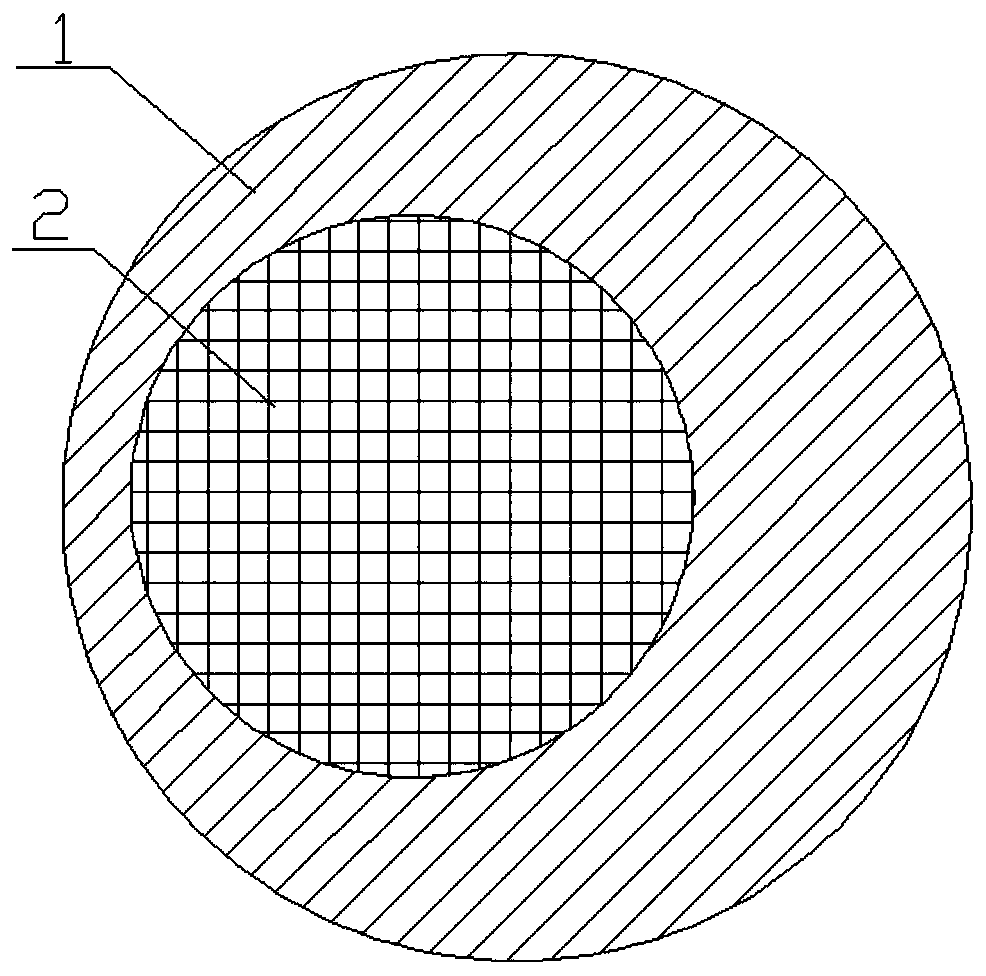

[0037] S3. The melt of the skin layer material and the melt of the core layer material are respectively extruded by their corresponding twin-screw extruders, and after metering, they are sprayed out through the nozzle of the eccentric sheath-core spinning assembly, and the spinning assemb...

Embodiment 1

[0041] The present embodiment provides a kind of preparation method of elastic fiber melt-blown non-woven fabric, comprises the following steps:

[0042] S1. Mix polypropylene elastomer slices, ultra-high molecular weight polyethylene slices, and nano-silicon carbide at a mass ratio of 91:6:3, and dry at 80°C for 4 hours to keep the moisture content below 150ppm, and extrude through twin-screw The machine melts and blends at 220° C. to form a skin layer material melt; the particle size of the nano-silicon carbide is 100 nm.

[0043]S2. Using maleic anhydride grafted polypropylene with a grafting rate of 1% as a compatibilizer, the ether-ester copolymer thermoplastic polyurethane elastomer slices and the compatibilizer are mixed according to a mass ratio of 92:8, and heated at 80°C Dry at low temperature for 4 hours to keep the moisture content below 150ppm, and melt blend at 200° C. through a twin-screw extruder to form a core layer material melt.

[0044] S3. The melt of the...

Embodiment 2~9 and comparative example 1~4

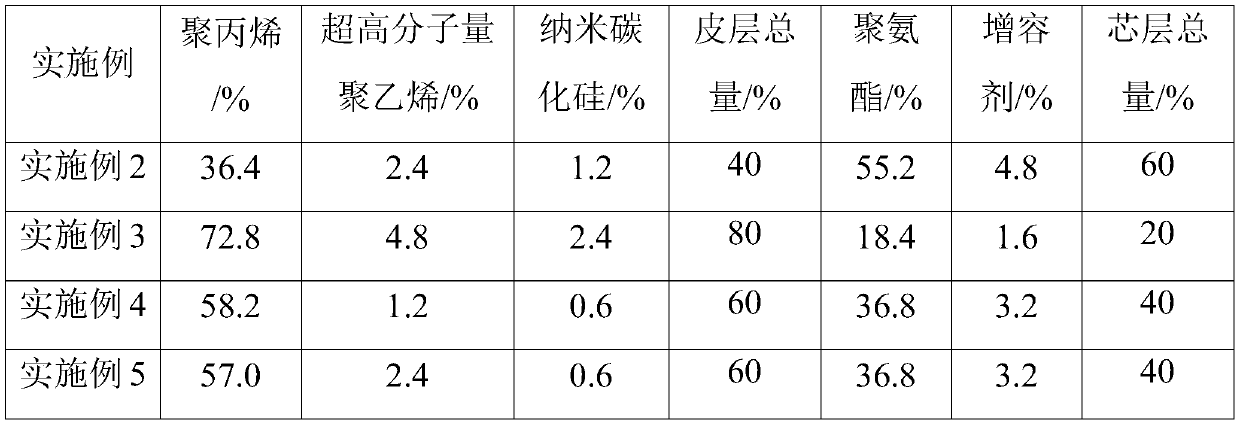

[0053] Examples 2 to 9 and Comparative Examples 1 to 4 respectively provide a method for preparing elastic fiber melt-blown non-woven fabrics. Compared with Example 1, the difference is that the content of each raw material in the composite fiber is changed, and each implementation The percentages of the mass of each raw material in the total mass of composite fibers in Examples and Comparative Examples are shown in Table 2.

[0054] Table 2 The percentage of each raw material mass in the total mass of the composite fiber in Examples 2 to 9 and Comparative Examples 1 to 4

[0055]

[0056]

[0057] The tensile strength, elongation at break and peel strength of the elastic fiber melt-blown nonwoven fabrics prepared in Examples 2-9 and Comparative Examples 1-4 were tested, and the results are shown in Table 3.

[0058] Table 3 The performance parameters of the elastic fiber melt-blown non-woven fabrics prepared in Examples 2-9 and Comparative Examples 1-4

[0059]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com