Composite carbon material for seawater desalination and preparation method of composite carbon material

A technology of composite carbon and activated carbon, which is applied in chemical instruments and methods, carbon compounds, seawater treatment, etc., can solve the problems of unsatisfactory capacitance performance of activated carbon and limit the application of capacitors, etc., and achieve clear pore structure, improved performance, and good ion transmission channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

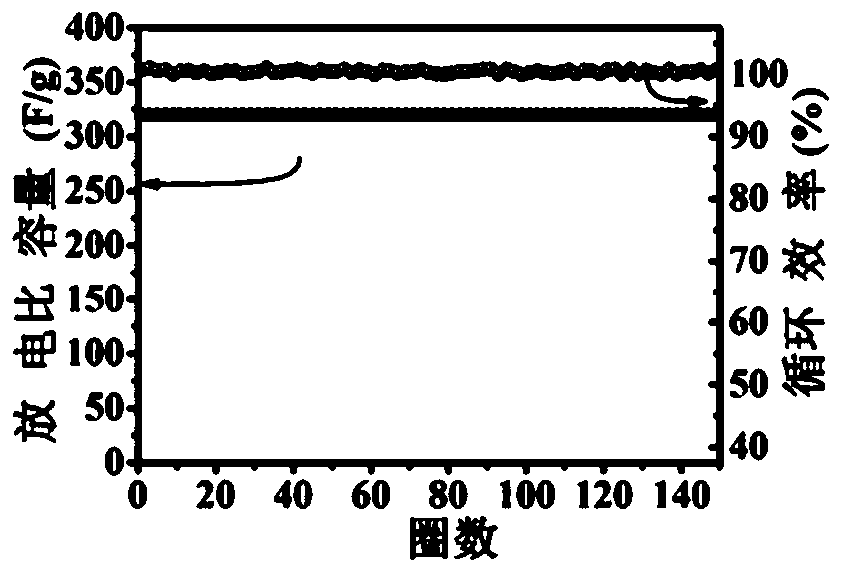

[0027] Embodiment 1 lotus pod as biomass carbon source

[0028] This embodiment prepares the method for composite carbon material to comprise the steps:

[0029] (1) Remove the lotus seeds from the fresh lotus pods, rinse them with tap water, put them into a 3000ml beaker, soak them in deionized water, ultrasonicate for 30 minutes, put them in a blast drying oven at 70°C for 16 hours, and finally put the dried lotus pods with Grinding into fine powder;

[0030] (2) Weigh 4g lotus powder and add it to a 250ml beaker, then weigh 6mol KOH and pour it into a 250ml beaker with 100ml deionized water, stir and dissolve under ultrasonic to prepare a mixed solution;

[0031] (3) Pour the mixed solution into a 100ml high-pressure reaction kettle, tighten it and put it in a blast drying oven, heat it at 1.5Mpa and 120°C for 2 hours, and pour it into two 50ml centrifuge tubes after cooling down After centrifuging at 8000r / min for three minutes, take the solid and put it in a vacuum dryi...

Embodiment 2

[0052] Embodiment 2 shower bar as biomass carbon source

[0053] The basic steps are the same as those in Example 1, except that the biomass carbon source used is shower stems, the activation temperature is 200°C, and the holding temperature of the tube furnace is 500°C.

Embodiment 3

[0059] Embodiment 3 lotus seed pod as biomass carbon source

[0060] The basic steps are the same as in Example 1, except that the carbon source used is lotus seed pods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com